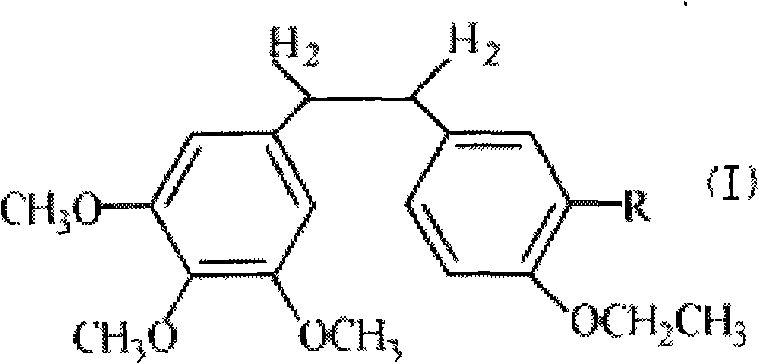

Ethoxy diphenyl ethane derivative and preparation method and application thereof

A technology of ethoxydiphenylethane and ethoxy, which is applied in the field of synthesis of anticancer drugs of diphenylethane derivatives, can solve the problem of reduced anticancer effect, difficulty in preservation and practical application of diphenylethylene compounds, Problems such as large loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

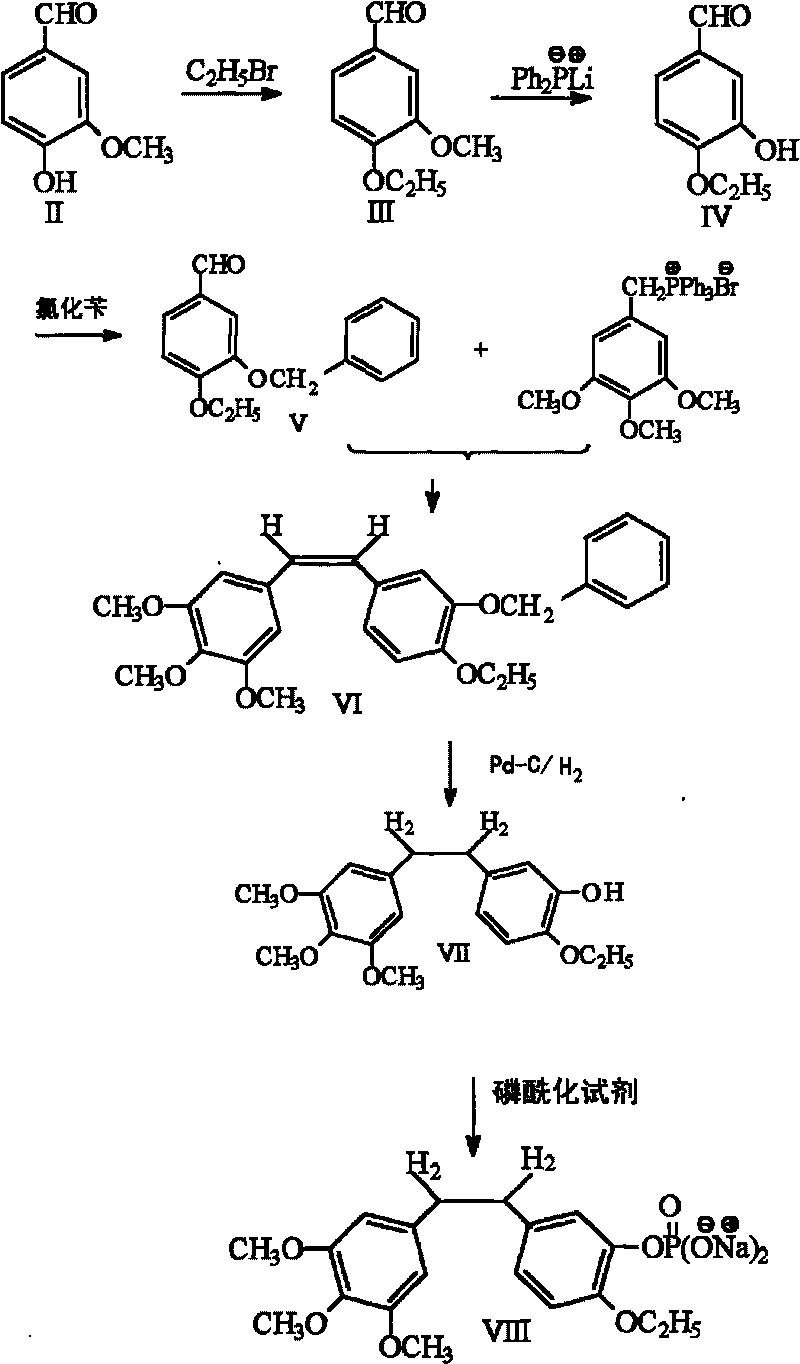

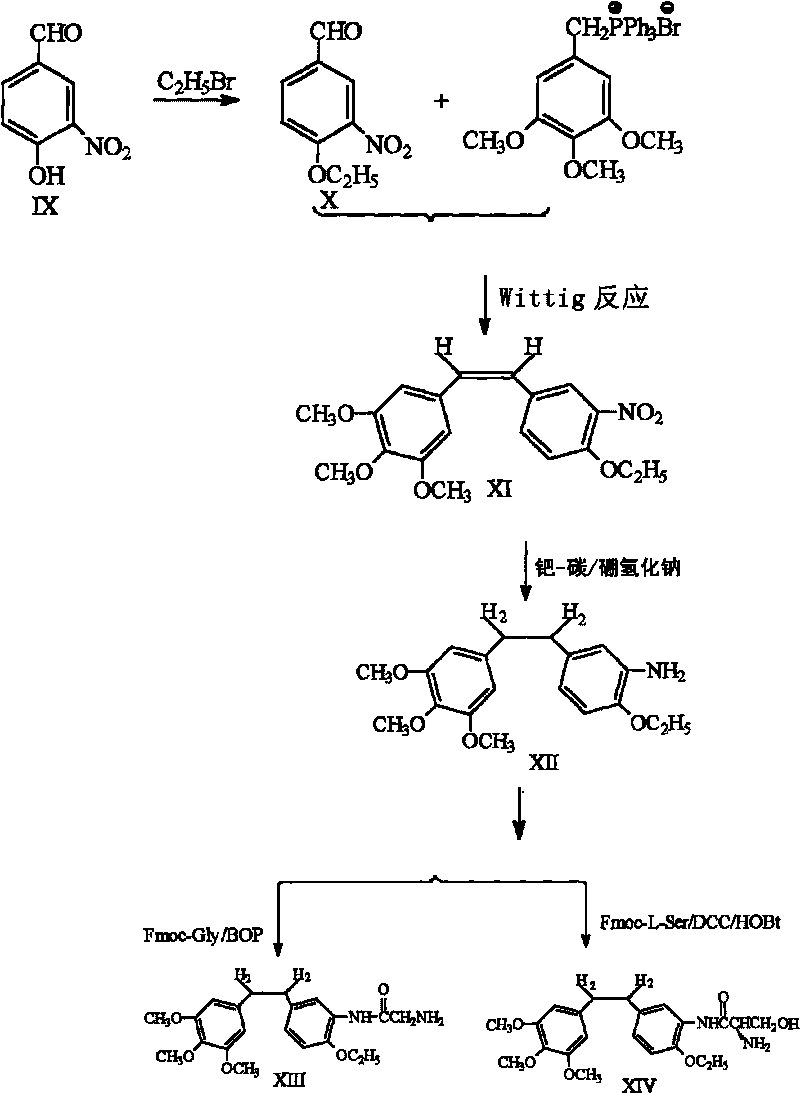

Method used

Image

Examples

Embodiment 1

[0069] Preparation of 4-ethoxy-3-methoxybenzaldehyde:

[0070]Add 76 grams (0.5mol) of 4-hydroxyl-3-methoxybenzaldehyde into the four-necked flask, 500mL isopropanol, stir for 20 minutes, slowly drip 6.5 grams of 18-crown-6 ether and 133 grams of sodium hydroxide in 150 milliliters of aqueous solution, stirred for 30 minutes, heated the reaction system to 60 ° C, at this temperature, added 85 grams of bromoethane dropwise, reacted for 5 to 6 hours, followed by TLC, and cooled the system after the reaction was completed down (15°C), adding 500mL of water to stop the reaction, the product was extracted with diethyl ether (3×300mL), the organic phase was washed with water until neutral, anhydrous MgSO 4 After drying, part of the ether was evaporated, and a large amount of petroleum ether was added to precipitate the crude product. Recrystallization with ether / petroleum ether gave 83 g of 4-ethoxy-3-methoxybenzaldehyde with a yield of 92%.

Embodiment 2

[0072] Preparation of 4-ethoxy-3-hydroxybenzaldehyde:

[0073] Step 1, under the protection of argon, get 54 grams (0.3mol) of 4-ethoxyl-3-methoxybenzaldehyde and join in the three-necked bottle, then add 130 grams (2.1mol) of ethylene glycol, 133 g (0.9 mol) of diethyl orthoformate was refluxed at about 100°C, and 1 ml of boron trifluoride ether solution was added as a catalyst. Reaction for 24 hours, followed by TLC, cooled to room temperature, added 200ml of 15% aqueous sodium hydroxide solution, extracted with 300ml of ether, washed with saturated brine, dried over anhydrous magnesium sulfate, evaporated ethylene glycol and triethyl orthoformate under reduced pressure , a yellow oil was obtained.

[0074] Step 2, in 200ml of 1.28M diphenylphosphine lithium tetrahydrofuran solution, add 56 grams (0.25mol) of the above-mentioned acetal in batches, stir at room temperature for 3-4 hours, TLC tracking, add water to stop the reaction, add 200ml of 30% hydrogen hydroxide After...

Embodiment 3

[0076] The preparation of 4-ethoxy-3-benzyloxybenzaldehyde:

[0077] Add 16.6g (100mmol) of 4-ethoxy-3-hydroxybenzaldehyde in the three-necked flask, 200ml of absolute ethanol, heat to 40°C to dissolve, add 9g of potassium carbonate (65.07mmol), and add 15ml of benzyl chloride ( 130.13mmol), heated to reflux for 1 hr, after TLC detected that the reaction was complete, cooled to 50°C, filtered while it was hot, cooled the filtrate in a refrigerator overnight, crystals were precipitated, filtered with suction, washed the filter cake with 30mL of absolute ethanol, and dried in vacuo, 21.5 g of white needle-like crystals were obtained with a yield of 83.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com