Solar battery for staggered power generating in situ

A solar cell and time-staggered technology, applied in photovoltaic power generation, circuits, fuel cell half-cells and primary battery-type half-cells, etc., to achieve real-time storage and use, easy miniaturization, and no carbon dioxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

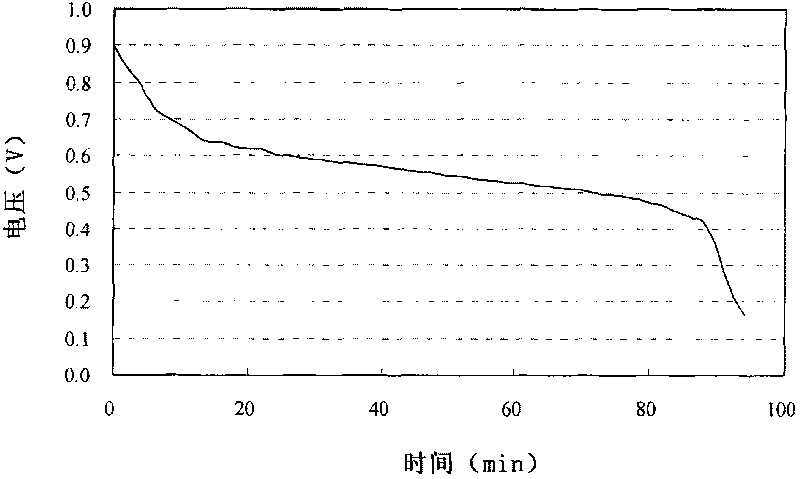

Embodiment 1

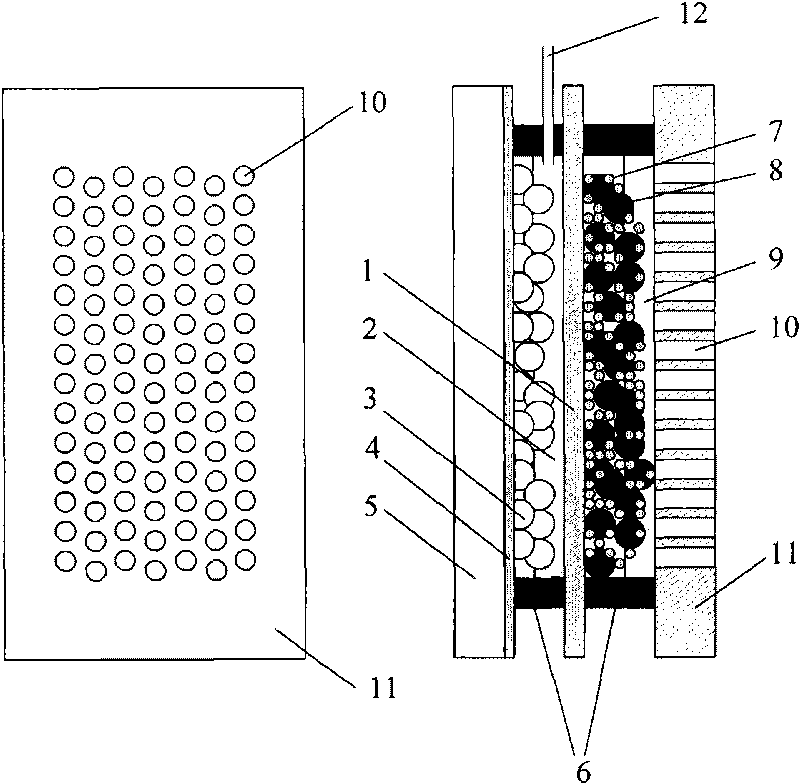

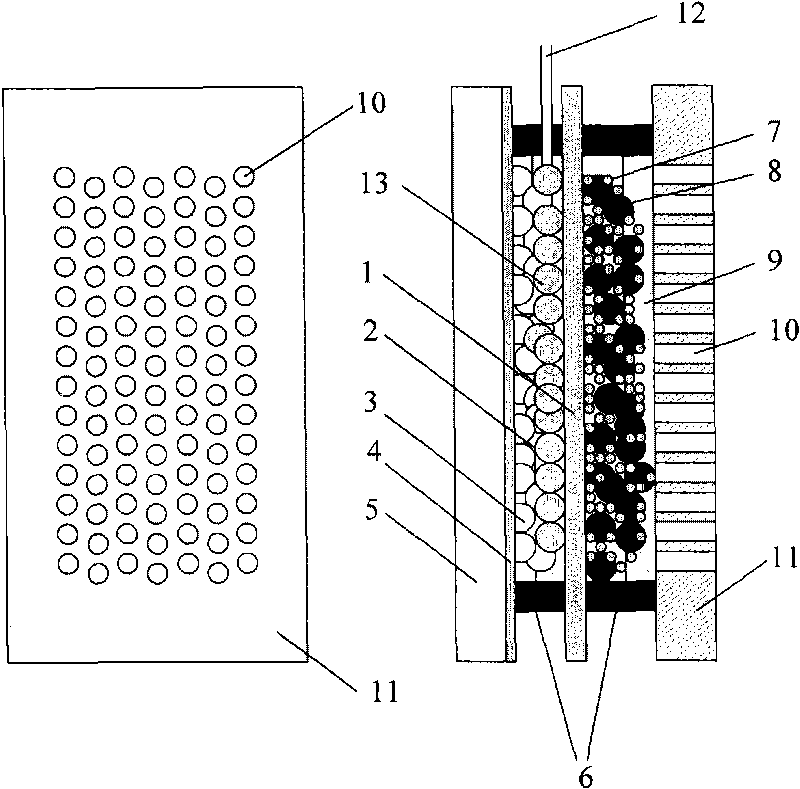

[0056] Example 1: Single layer photolysis of water hydrogen storage material negative electrode

[0057] Take TiCr with a particle size of about 100nm 2 The alloy powder was heat-treated at 800°C for 0.2 hours in an argon-oxygen mixed atmosphere with an oxygen content of 5%, and the obtained powder was immersed in a 30wt% NaOH solution at a temperature of 50°C, stirred and impregnated for 1 hour, and used After washing with ion water and vacuum drying, anatase TiO with a film thickness of 5 nm was obtained. 2 A photolytic water-splitting hydrogen storage material that forms a thin film with metal Cr particles. Take 0.5 g of the photolytic water hydrogen storage material and put it into a mortar, grind and mix it with binder: polypropylene alcohol (PVA) aqueous solution (concentration: 5wt.%), and apply it to a carbon paper with an area of 1.5×1.0 square centimeters Above, the mass ratio of photolytic water-splitting hydrogen storage material to PVA is 1:0.1. After drying,...

Embodiment 2

[0058] Example 2: A multilayer negative electrode composed of photolytic water hydrogen storage materials and general hydrogen storage materials

[0059] Take general hydrogen storage material LaNi 4.5 al 0.5 (4.5 al 0.5 The mass ratio to PVA is 1:0.1, and it is ready to use after drying.

[0060] Take TiCoAl with a particle size of about 100nm 0.1 The alloy powder was heat-treated at 600°C for 3 hours in an argon-oxygen mixed atmosphere with an oxygen content of 1%. The obtained powder was immersed in a NaOH solution containing 30 wt% at a temperature of 90 °C, stirred and impregnated for 0.2 hours, washed with deionized water and dried in vacuum to obtain anatase TiO with a film thickness of 20 nm. 2 A photo-splitting water-splitting hydrogen storage material that forms a thin film with Co metal particles. Take 0.5 g of the photolytic water hydrogen storage material and put it into a mortar, grind and mix it with binder: polypropylene alcohol (PVA) aqueous solution (con...

Embodiment 3

[0061] Example 3: Positive Electrode Fabrication

[0062] Add 10 grams of carbon material to 300 ml of water to form a suspension, add 5 g of glacial acetic acid and stir at room temperature for 20 minutes, and adjust the pH to 3.0. Then add 2g of pyrrole monomer and stir for 5min, then add 10ml of 30wt.%H 2 o 2 As a polymerization initiator, stir at room temperature for 3h. The product was washed with warm deionized water, and dried under vacuum at 90° C. for 12 hours to obtain a polypyrrole-modified carbon material with a polypyrrole content of 15 wt.%.

[0063]Mix the carbon-supported cobalt hydroxide catalyst modified by polypyrrole, water, polytetrafluoroethylene emulsion and absolute ethanol according to the mass ratio of 1:4.5:7:4.5 to prepare a slurry, and then evenly apply it to an area of 1.5× 1.0 square centimeters of carbon cloth after hydrophobic treatment, baked at 350 ° C for 1 hour, and naturally cooled to room temperature to prepare a positive electrode w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com