Method of preparing transition metal oxide nano-particles

A technology of transition metals and nanoparticles, applied in the direction of nanostructure manufacturing, rare earth metal compounds, chromium oxide/hydrate, etc., can solve the problems of mass production obstacles, reproducibility reduction, pollution hazards, etc., and achieve easy reactivity, easy Controlling, Response Stabilizing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A peroxide-metalate solution having a Ti concentration of 0.14M was prepared by dissolving Ti metal powder (Aldrich, 268496) in a 30 wt% aqueous hydrogen peroxide solution. Then, isopropanol:water:nitric acid was mixed at a volume ratio of 1:1:0.1 to prepare a reaction solution, and 5 mL of the peroxide-metalate solution and 5 mL of the prepared reaction solution were mixed to prepare a mixed solution.

[0030] After filling the prepared mixed solution into an autoclave, a hydrothermal reaction was performed in an oven at 120°C for 2 hours to produce TiO 2 Anatase nanoparticles.

Embodiment 2

[0032] A peroxide-metalate solution having a Ti concentration of 0.005M was prepared by dissolving W metal powder (Aldrich, 510106) in a 30 wt% aqueous hydrogen peroxide solution. Then, isopropanol:water:nitric acid was mixed at a volume ratio of 1:1:0.14 to prepare a reaction solution, and 36 mL of the peroxide-metalate solution and 72 mL of the prepared reaction solution were mixed to prepare a mixed solution.

[0033] After filling the prepared mixed solution into an autoclave, a hydrothermal reaction was carried out in an oven at 98°C for 1 hour to produce WO with a hexagonal structure. 3 Nanoparticles.

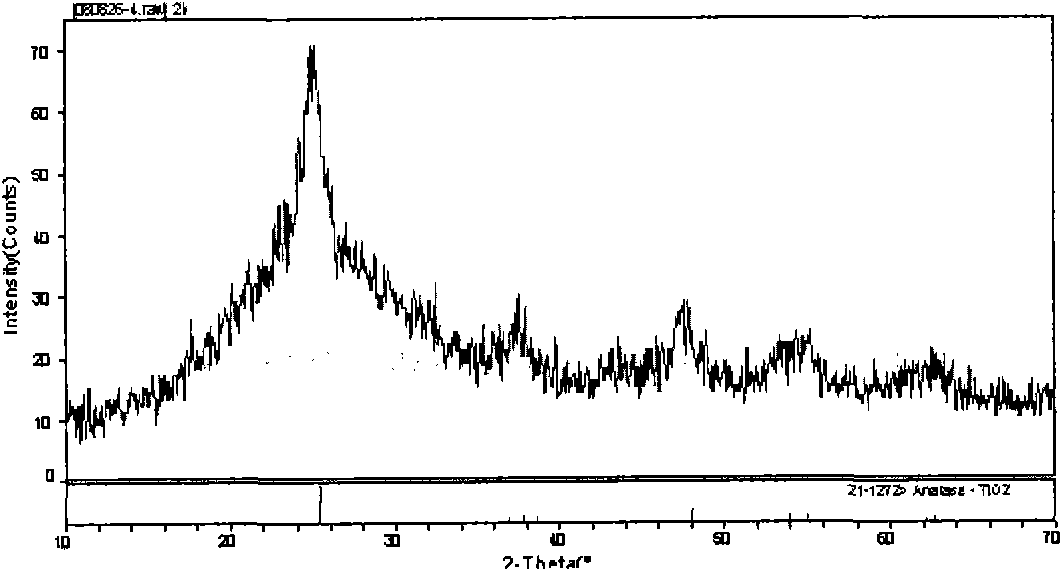

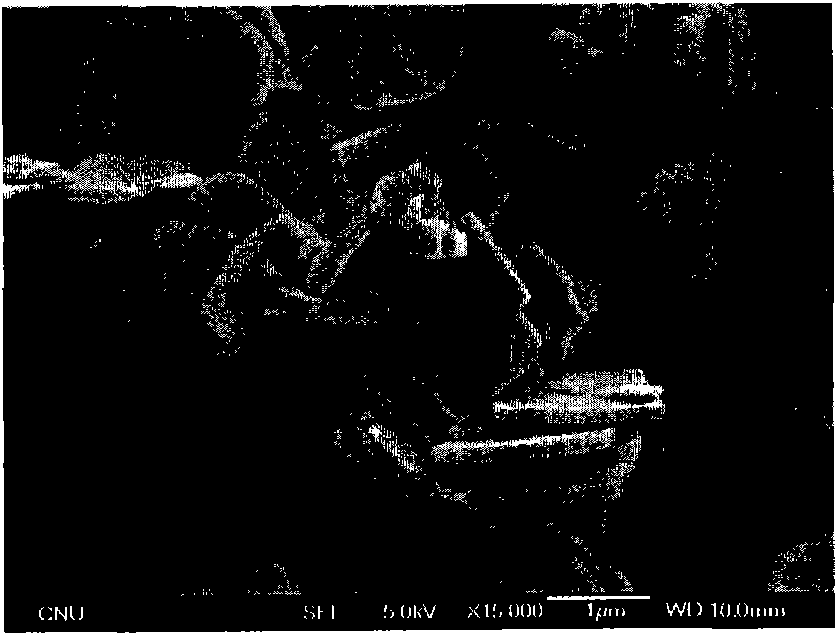

[0034] figure 1 is a scanning electron micrograph of titanium dioxide manufactured in Example 1 of the present invention, figure 2 is the X-ray diffraction analysis result of titanium dioxide produced in Example 1, image 3 It is a scanning electron micrograph of tungsten oxide produced in Example 2.

[0035] Depend on figure 1 with image 3 It can be seen from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com