Aqueous ultraviolet cured epoxy acrylic resin and preparation method thereof

A technology of epoxy acrylate and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of high freezing point, low gloss of cured film, and influence on dispersion, and achieve the effect of less environmental pollution and simplified operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

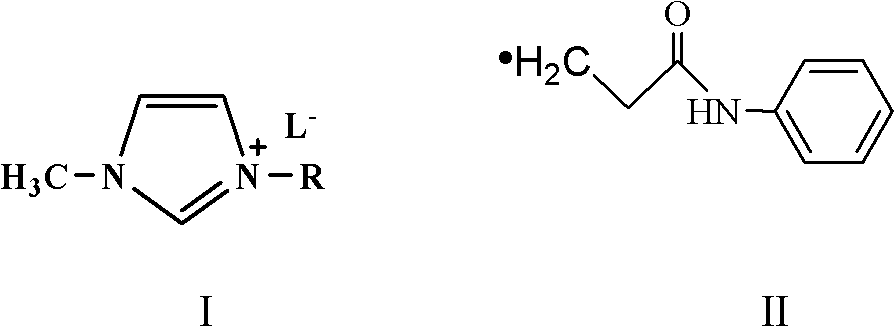

[0065] The preparation of embodiment 1 ionic liquid catalyst

[0066] Taking 1-octyl-3-methylimidazolium tetrafluoroborate ionic liquid as an example, the preparation method is: add 1 mole of bromooctane (reactant A) and 1 mole of N-methylimidazole (reactant B) In the three-necked flask, heat and reflux for 10 hours, after cooling to room temperature, add 5 times the volume of the reaction solution in water, then add 1mol sodium tetrafluoroborate (reactant C), stir at room temperature for 10 hours, extract with dichloromethane, no Dry over sodium sulfate, filter and concentrate to obtain 1-octyl-3-methylimidazolium tetrafluoroborate ionic liquid.

[0067] The ionic liquids a to c were prepared according to the above method steps, the difference was that the raw materials were changed, wherein the reactant A, reactant B and reactant C are shown in Table 1 below.

[0068] Table 1:

[0069] Numbering

ionic liquid

Reactant A

Reactant B

Reactant C

...

Embodiment 2

[0072] Embodiment 2 Preparation of water-based UV-curable epoxy acrylate resin

[0073] Using 3-(N-phenylcarbamoylethyl)-1-methylimidazolium hexafluorophosphate ionic liquid

[0074] In a four-neck flask equipped with a stirrer, condenser, constant pressure funnel, and thermometer, add 4 grams of hydroquinone polymerization inhibitor and 340 grams of bisphenol A epoxy resin, heat to 70 ° C, and start to drop under stirring Add 144 grams of acrylic acid and 7 grams of catalyst 3-(N-phenylcarbamoylethyl)-1-methylimidazolium hexafluorophosphate ionic liquid. After the addition is complete, the temperature is raised to 85° C., and samples are taken every half hour to determine the acid concentration. Value once, until the acid value is 4.5mgKOH / g, stop the reaction and lower the temperature. When the temperature of the above system drops to 70°C, add 7 grams of catalyst, and after fully stirring evenly, add 4 grams of hydroquinone polymerization inhibitor and 196 grams of maleic ...

Embodiment 3

[0075] Embodiment 3 Preparation of water-based ultraviolet light curing epoxy acrylate resin

[0076] Using 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid

[0077] In a four-neck flask equipped with a stirrer, condenser, constant pressure funnel, and thermometer, add 2 grams of hydroquinone polymerization inhibitor and 340 grams of bisphenol A epoxy resin, heat to 60 ° C, and start to drop under stirring Add 144 grams of acrylic acid and 2 grams of catalyst 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid, raise the temperature to 80°C after the dropwise addition, and measure the acid value by sampling every half hour until the acid value is 4.9mgKOH / g, stop the reaction and cool down. When the temperature of the above-mentioned system drops to 60°C, add 2 grams of catalyst, and after fully stirring evenly, add 2 grams of hydroquinone polymerization inhibitor and 196 grams of maleic anhydride, raise the temperature to 80°C, and measure the acid conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com