Preparation method for borate antibacterial glass coating with bioactivity and application thereof

A borate glass and bioactive technology, applied in coatings, medical science, prostheses, etc., can solve the problems of non-antibacterial properties and inability to fully adapt to surgical requirements, achieve high antibacterial efficiency, and reduce diseases caused by bacteria , the effect of little harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

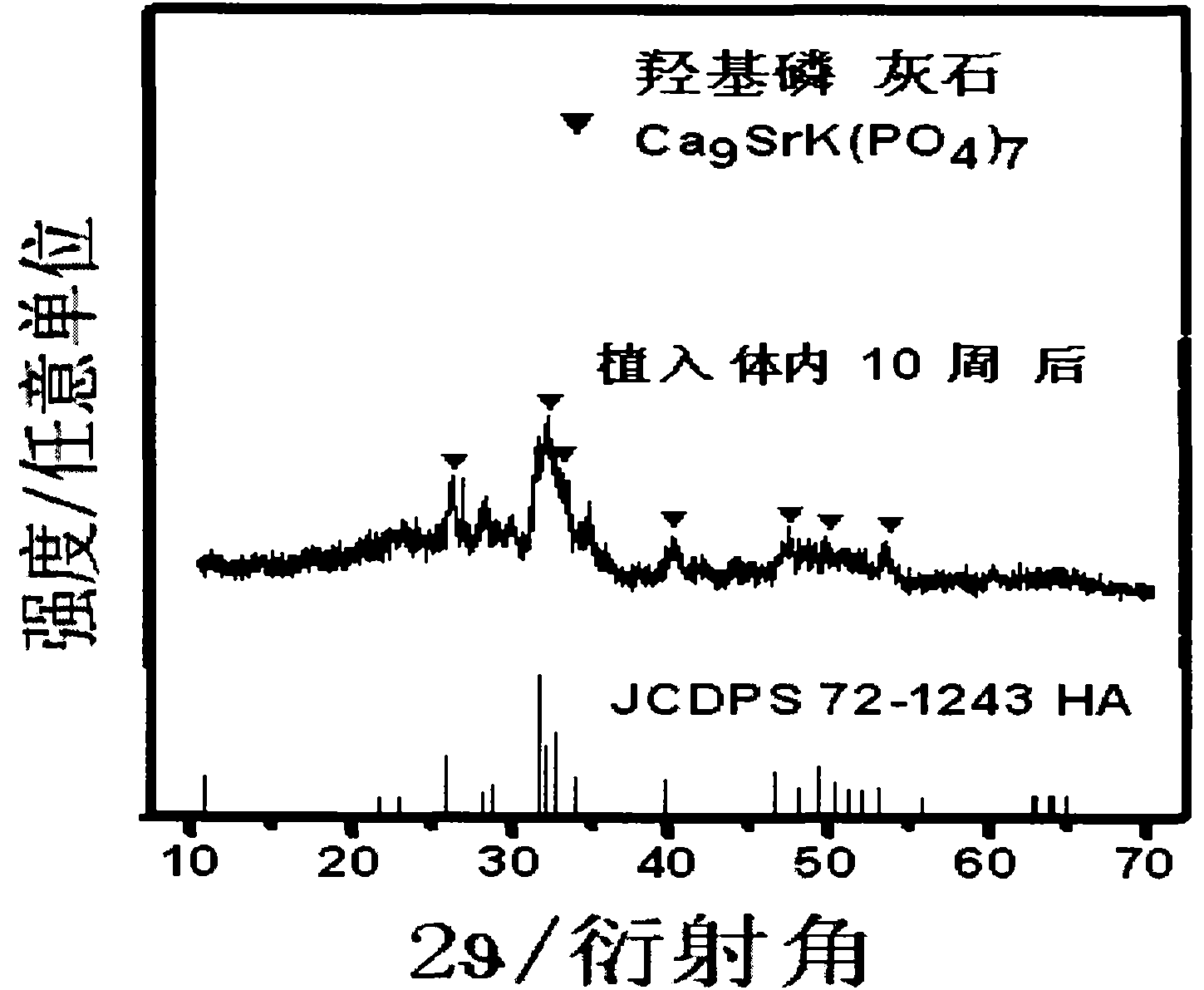

[0018] Embodiment 1 Preparation of silver-containing borate glass coating

[0019] (1) Preparation of borate glass with 1.0% silver content

[0020] Weigh 2.926g anhydrous sodium carbonate, 7.107g anhydrous potassium carbonate, 4.995g basic magnesium carbonate, 10.294g calcium carbonate, 5.694g strontium carbonate, 6.951g silicon dioxide, 29.473g boric acid, 3.419g sodium dihydrogen phosphate , 0.529g silver phosphate. After grinding, mix well to get the raw ingredients.

[0021] After putting the ingredients into a platinum crucible, put it in a temperature of 1150°C for 120 minutes, and then pour the obtained clear glass liquid on a preheated steel plate to obtain a glass block.

[0022] The glass block is crushed and sieved to obtain glass particles with an average particle size of about 2-50um.

[0023] (2) The preparation of the coating adopts any of the following methods:

[0024] (1) After washing and drying the glass particles obtained in step (1), weigh 0.15 g and...

Embodiment 2

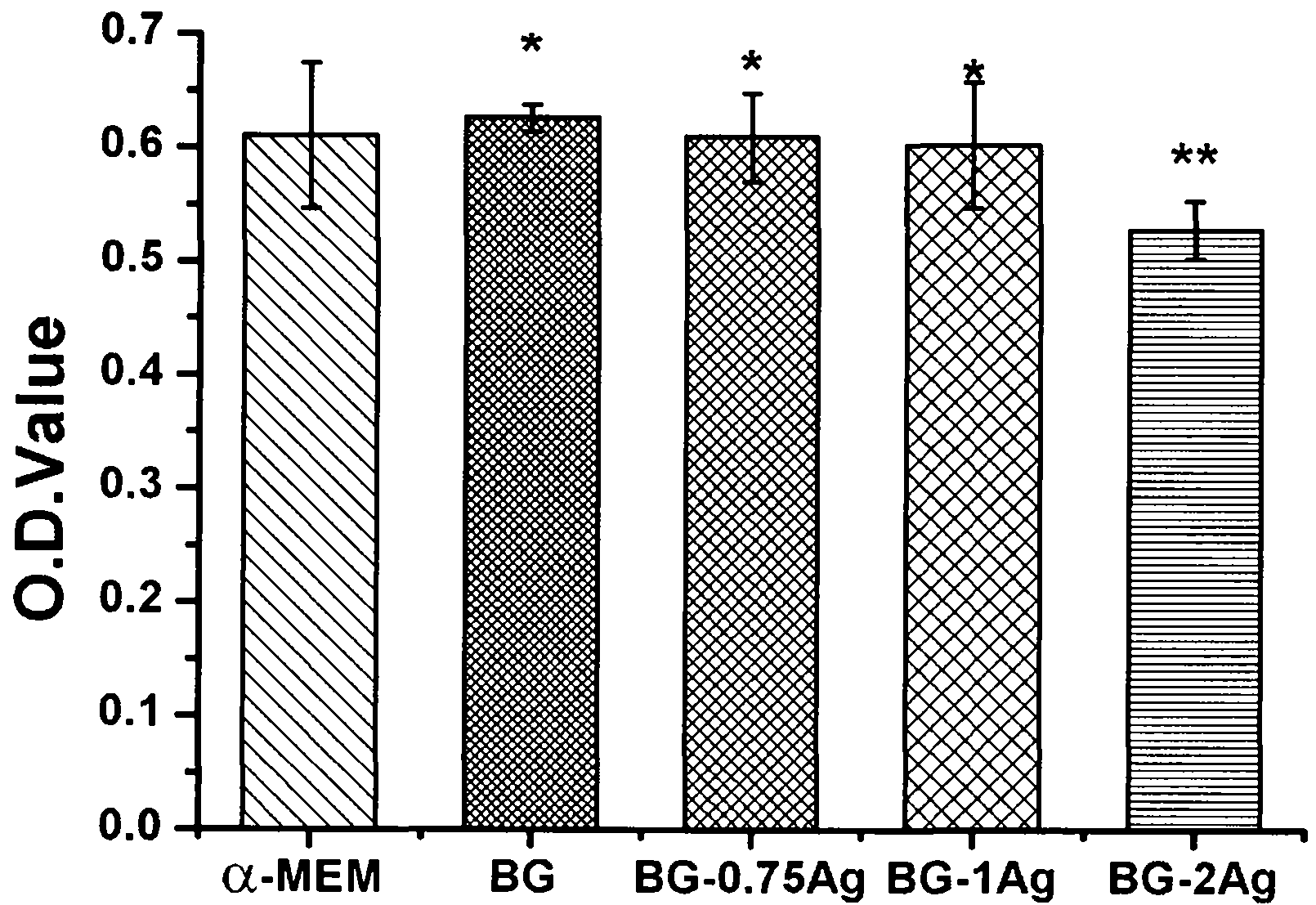

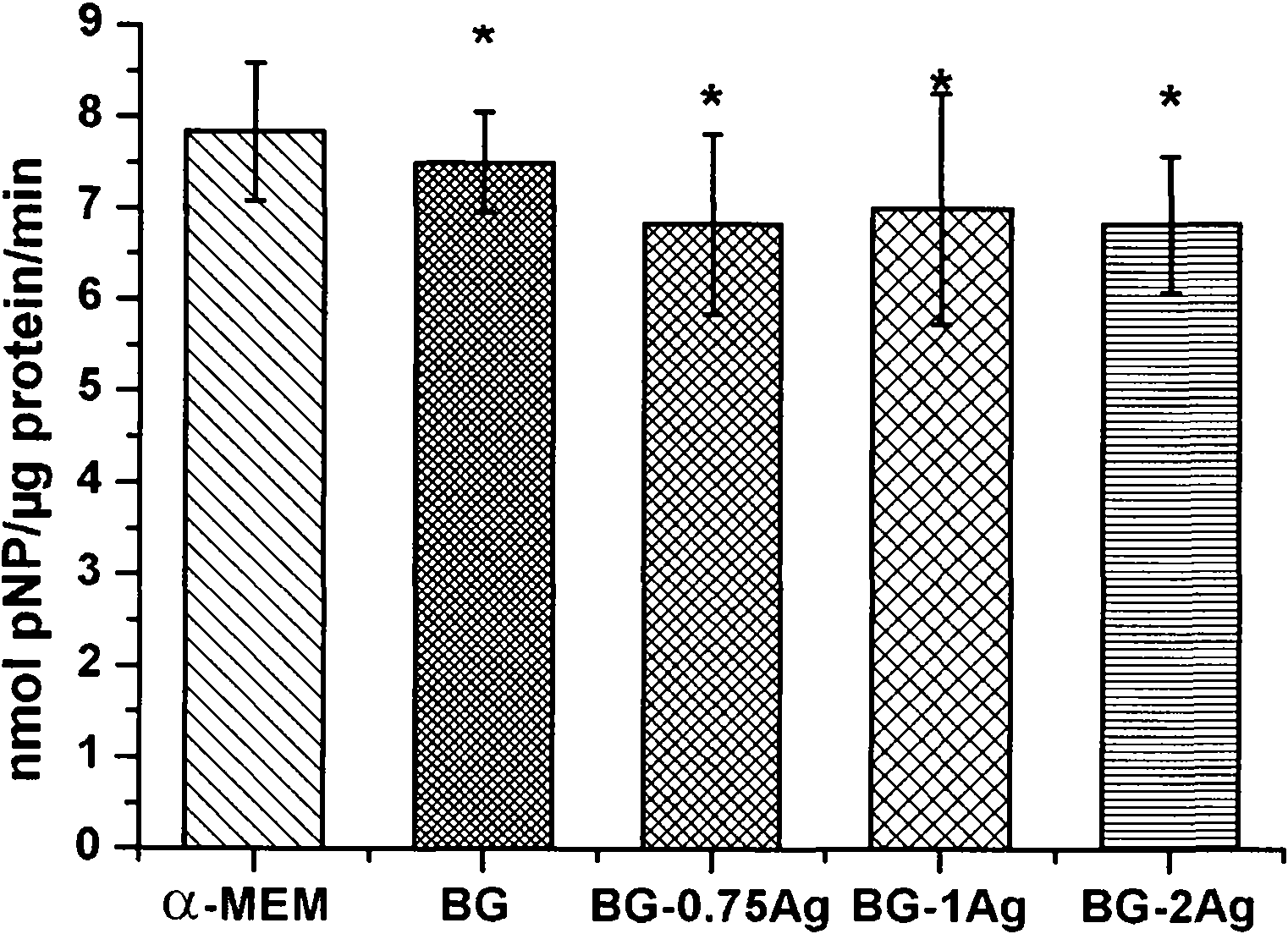

[0033] Example 2: Antimicrobial properties of coatings containing silver borate glass coatings

[0034] According to the method of Example 1, 0.265g, 0.529g, 0.794g, and 1.058g of silver phosphate were added to the formula of the glass to prepare four kinds of glass blocks containing AgO of 0.5, 1.0, 1.5 and 2.0wt%, respectively. According to the method of Example 2, four kinds of leaching solutions of glass coating blocks were obtained. Separately place Escherichia coli ATCC259 and Staphylococcus aureus ATCC25923 on the blood agar plate before the test, incubate at 35°C for 18 hours, then pick 2 to 3 colonies of Escherichia coli and Staphylococcus aureus on the blood plate and place them in the broth , 35 ℃ egg incubation 2h. Use a micro-sampler to take a certain amount of bacterial liquid and add it to the extracts arranged from low concentration to high concentration in sequence. The results show that the lowest concentration of the extract without visible growth is its an...

Embodiment 3

[0038] Embodiment 3: Bacteriostatic properties of copper-containing and zinc-containing borate glass coatings

[0039] According to the method described in Example 1, in the glass formulation, silver phosphate is replaced by copper sulfate, and 6.818g, 13.636g, and 20.454g CuSO are added respectively to make three kinds of borate glasses with different copper contents, and then Copper-containing borate glass coatings with 5%, 10%, and 15% copper ion mass percentages were prepared. In the same way, 2.172g, 4.344g, and 6.516g of zinc oxide were added to the glass batch material respectively, and three kinds of zinc-containing borate glasses with 5%, 10%, and 15% zinc ion mass percentages were prepared in the same way. coating.

[0040] Add sterilized common nutrient agar medium into a sterile petri dish to cover the entire bottom of the petri dish with a thickness of about 2.5mm, and then evenly coat the medium at a concentration of 10 7 cfu / ml of Escherichia coli (Escherichia c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com