Glass for photo-thermal generation heat-collecting pipe

A technology of photothermal power generation and heat collecting tubes, applied in the field of large-diameter glass materials, can solve the problems of poor airtightness, poor exposure resistance, and inability to use outdoors, and achieve wettability, good bonding strength, and improved airtightness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

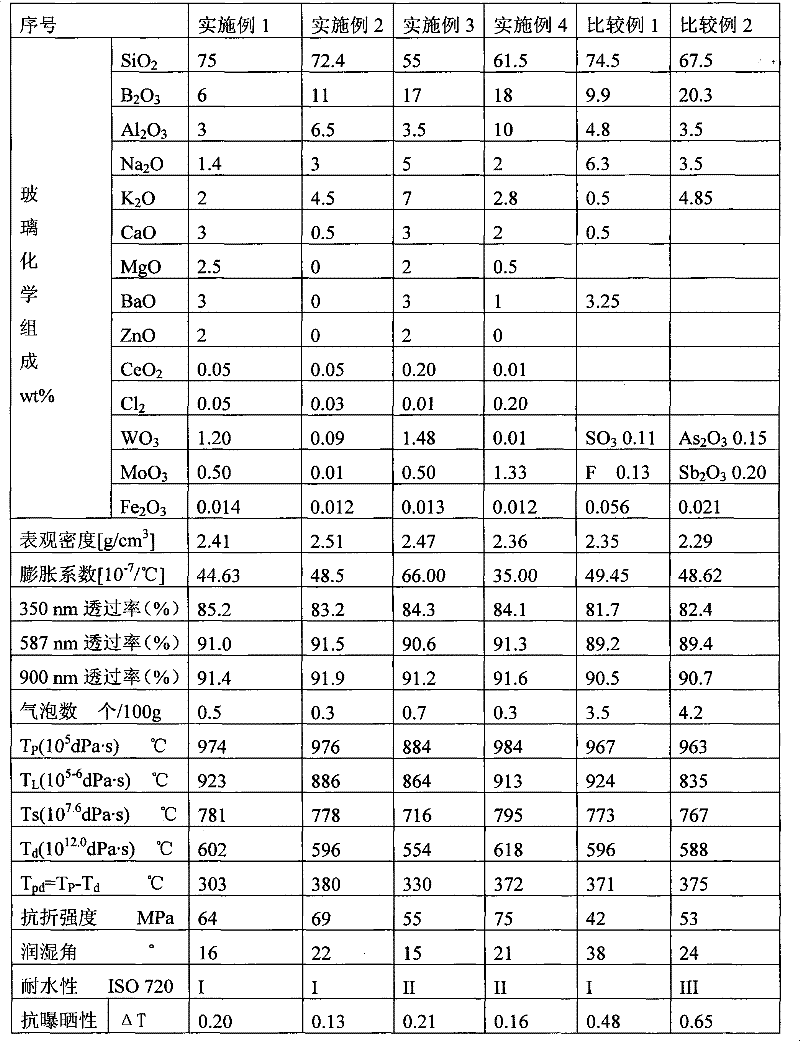

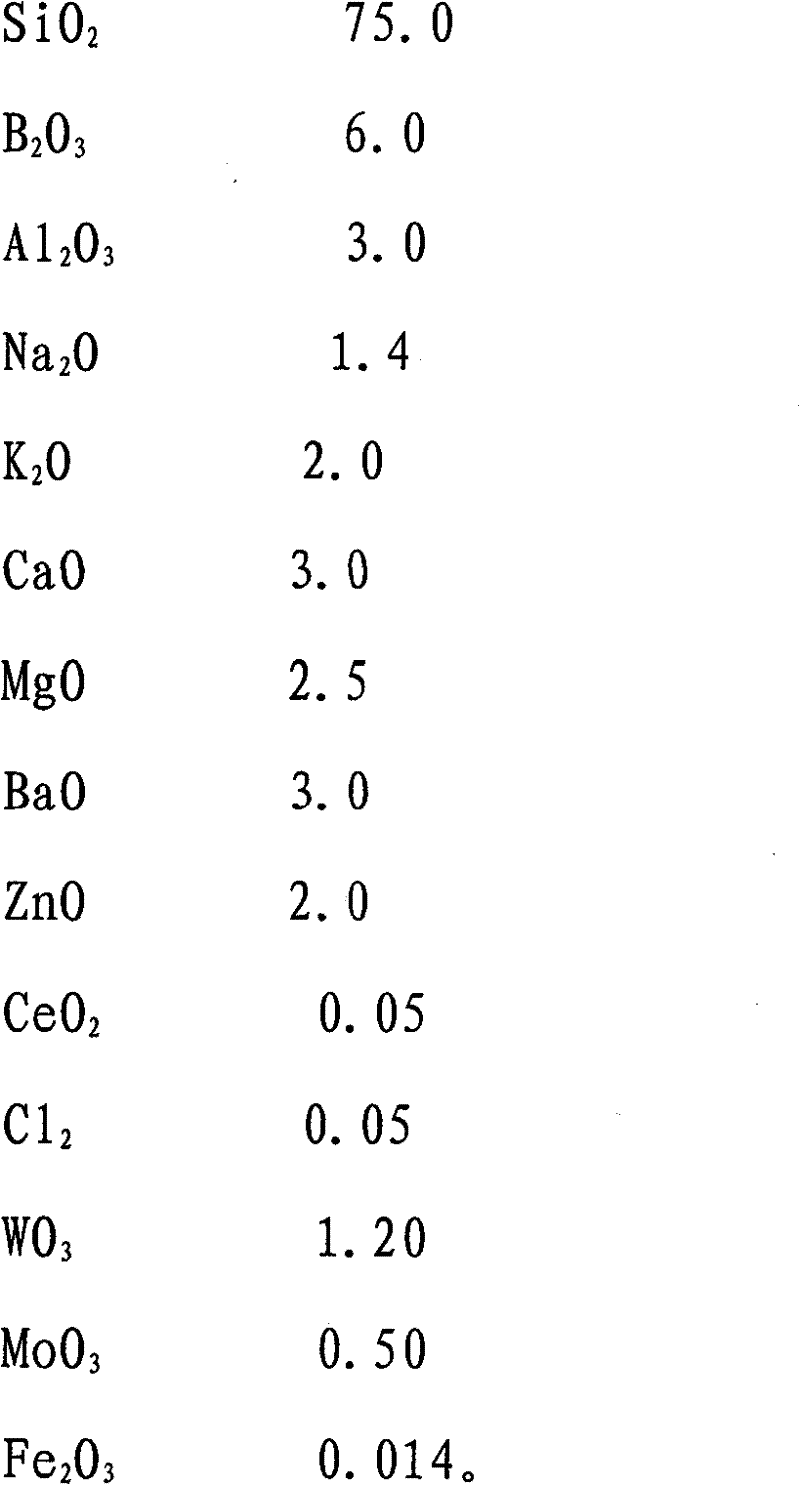

[0045] The present invention is described based on the embodiments, and Table 1 is the composition and performance of the embodiments of the present invention and comparative examples.

[0046] The chemical composition and performance table of table 1 embodiment and comparative example

[0047]

[0048] First, select the raw material according to the glass composition of Example 1 in Table 1, the raw material requirements, quartz sand (the 150 μm sieve is less than 1%, the 45 μm sieve is less than 30%, Fe 2 o 3 content less than 0.010wt%), aluminum hydroxide or aluminum oxide (average particle size 50μm), boric acid or borax (400μm sieve is less than 10%, 63μm sieve is less than 10%), calcium carbonate (average particle size 250μm ), barium carbonate (average particle size 50 μm), zinc oxide (average particle size 10 μm sieve 1% or less), as other glass components, use reagent grade magnesium carbonate, magnesium oxide, sodium chloride, ammonium chloride , barium chloride...

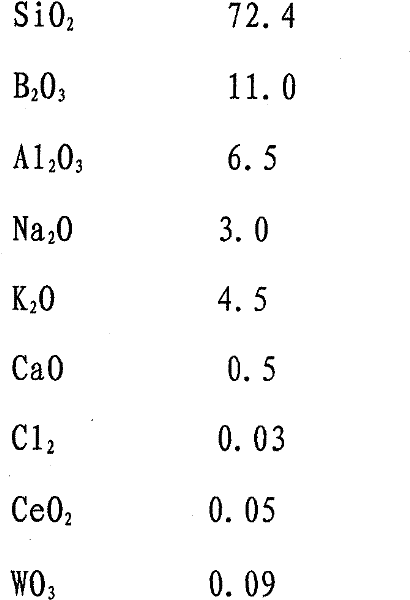

Embodiment 2

[0064] The actual composition of the glass refers to Example 2 of Table 1, using the same raw materials and raw material requirements as in Example 1, the clarifiers selected are sodium chloride and cerium carbonate, the amount of sodium chloride is 0.10%, and the remaining Cl in the glass 2 The amount is 0.03%; the amount of cerium carbonate is 0.10%, and the amount of sodium nitrate is 0.8%, so that the ingredients meet the glass composition in Table 1, and then use a platinum crucible to melt at a temperature of 1580 ° C for 24 hours. After melting, the melt is hydroformed to the specified test article requirements and then annealed. The basic properties of the samples are shown in Table 1.

[0065] On the whole, compared with Comparative Example, the glass of Example 1 has a better clarification effect, the number of bubbles per 100 grams of glass is less than 1, has a good spectral transmittance, has a moderate expansion coefficient, and can be applied to molybdenum metal...

Embodiment 3

[0067] The actual composition of the glass refers to Example 3 of Table 1, using the same raw materials and raw material requirements as in Example 1, the clarifiers selected are ammonium chloride and cerium oxide, the amount of ammonium chloride is 0.05%, and the remaining Cl in the glass 2 The amount is 0.01%; the amount of cerium oxide is 0.20%, and the amount of sodium nitrate is 1.0%, so that the ingredients meet the glass composition in Table 1, and then use a platinum crucible to melt at a temperature of 1580 ° C for 24 hours. After melting, the melt is hydroformed to the specified test article requirements and then annealed. The basic properties of the samples are shown in Table 1.

[0068] On the whole, compared with the comparative example, the glass of Example 1 has a better clarification effect, the number of bubbles per 100 grams of glass is less than 1, and it has a good spectral transmittance. With a moderate expansion coefficient, it can be applied to the seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com