Clean production method for preparing xylitol by using agricultural and forestry waste

A technology of agricultural and forestry waste and xylitol, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as high energy consumption, high pollution, and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

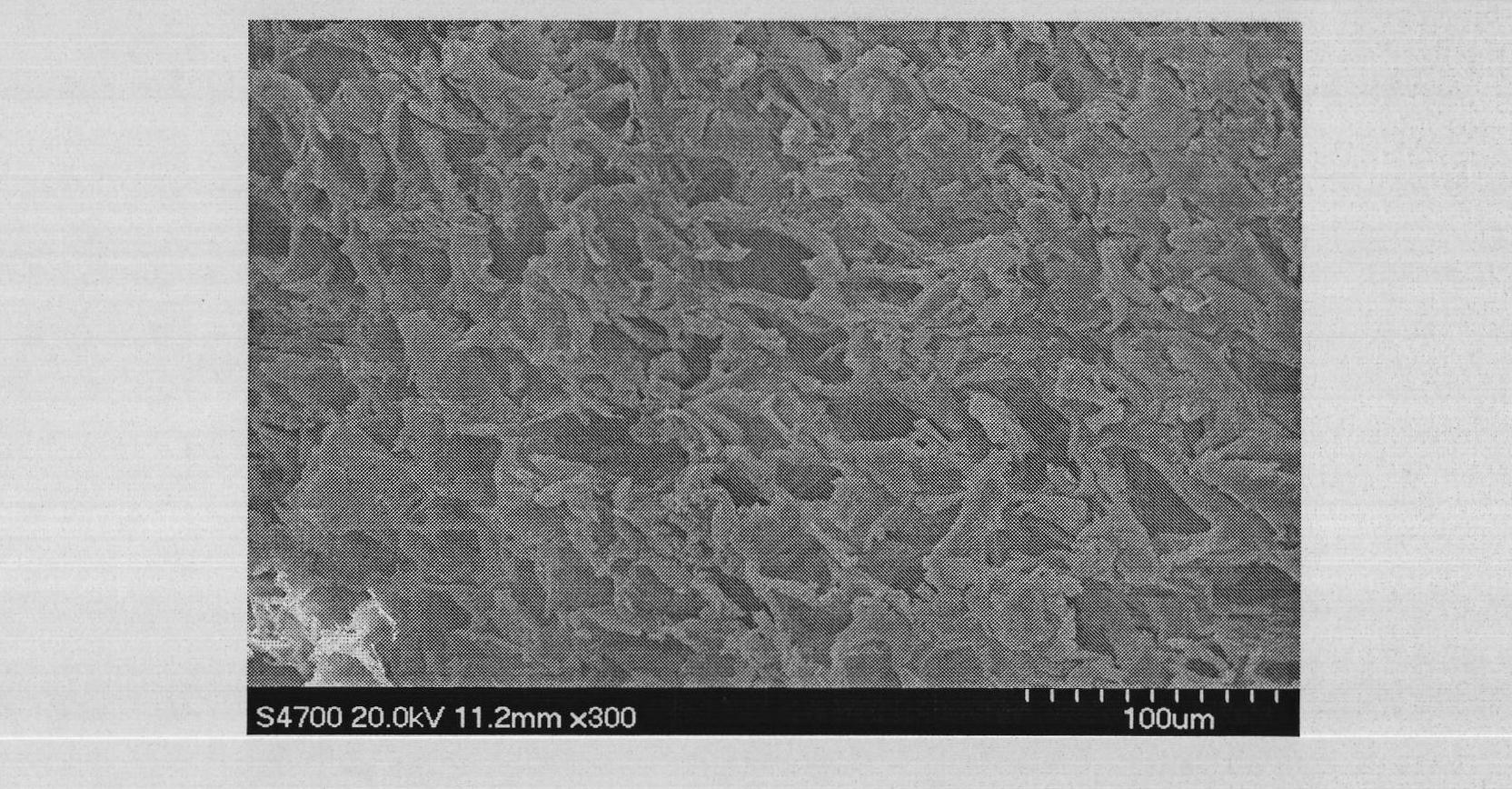

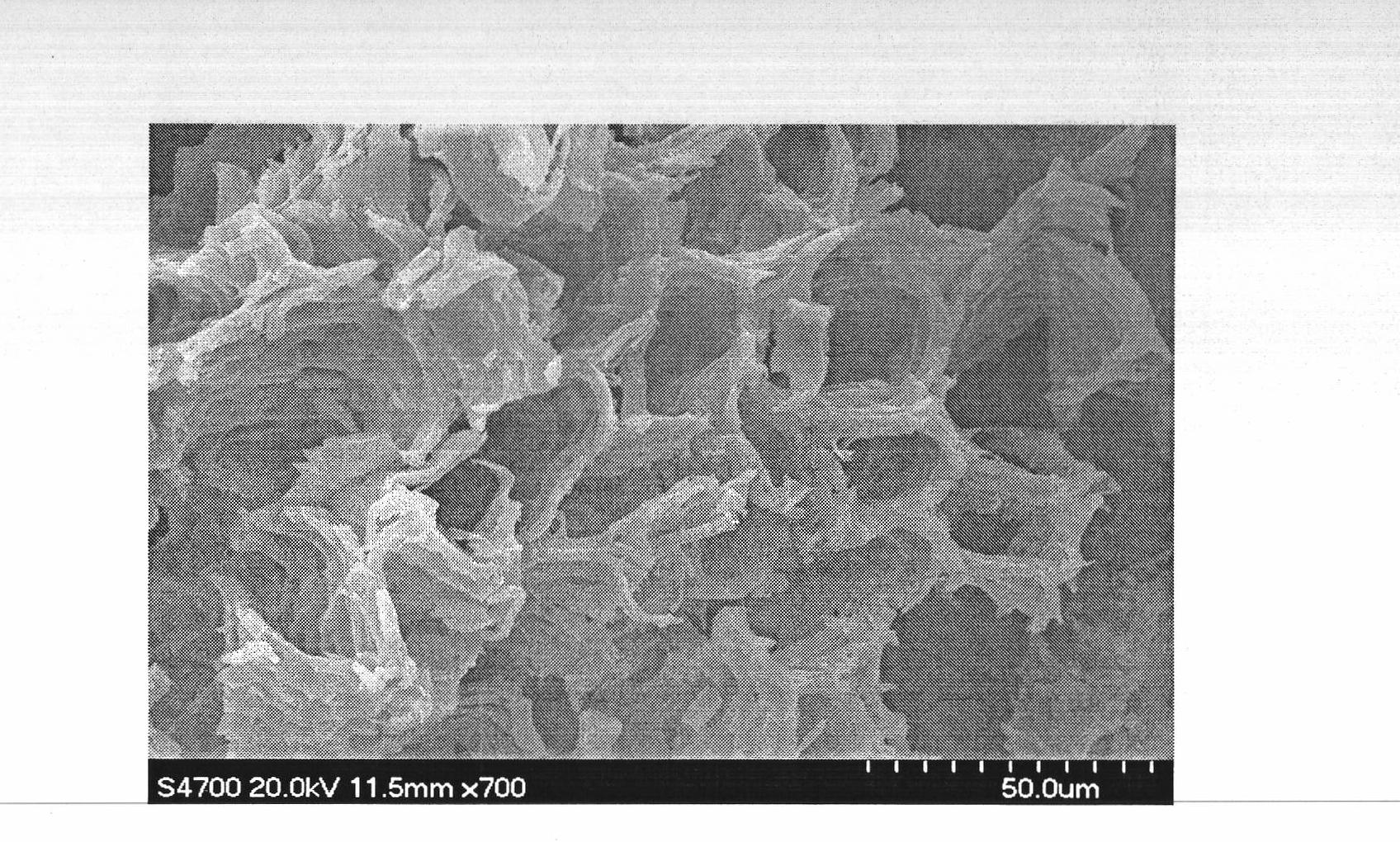

[0056] Corn cob pretreatment process

[0057] After crushing, dedusting, and water washing pretreatment, the corncob particles weighed 10Kg after being air-dried, added 50L of sulfuric acid solution with a mass fraction of 0.2%, soaked in a water bath at 50°C for 24 hours, and could be left standing or stirred appropriately to make the pigment Dissolution, particle swelling; plate filter to collect dilute acid solution for reuse, filter to obtain corn cob solids, wash the corn cob with a certain amount of deionized water, wash off the attached acid solution, and adjust the surface and internal ions of the corn cob strength.

[0058] Preparation of hydrolyzate by high temperature cooking

[0059] The granular corncobs (dry weight 6Kg) that have been pretreated and soaked in dilute acid are added to a high-temperature reactor, 75L of tap water is added, sealed and heated at high pressure, the temperature is set at 165°C, and the temperature is kept at a stirring speed of 60-150...

Embodiment 2

[0082] Example 2. Preparation of xylitol by fermentation in a cooking liquid fermenter

[0083] The seed liquor cultivated in the seed tank of Example 1 is pumped into the fermenter, the inoculation amount is 10% (volume fraction), and the temperature in the fermenter is maintained at 30°C; potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer salt is added The pH of the fermentation broth in the tank is controlled at 6.0; the ventilation rate adopts the three-step method of dissolved oxygen regulation method: the dissolved oxygen level in the fermentation tank is controlled in three ways of ventilation rate in different periods during the whole fermentation process. Adjust the ventilation in the tank to 1.1vv in the early stage of fermentation -1 m -1 , the rotation speed is 250rpm, when the wet weight of the bacteria reaches 25g / L, that is, when the fermentation time is 16h, adjust the ventilation in the tank to 0.6vv -1 m -1 , the rotation speed is 210rpm,...

Embodiment 3

[0085] Embodiment 3. Shake flask multi-batch fermentation prepares xylitol

[0086] According to the fermentation results of a single batch in Example 1, the yeast after the fermentation was reverted to produce xylitol by continuous fermentation. The method adopted for batch fermentation can adopt the following two methods: one is to put the empty triangular flask and the fresh medium to be batched into the ultra-clean bench, and sterilize it for 15 minutes by ultraviolet light. The shake flask completed for the first time is left to stand for about 15 minutes, so that the bacteria naturally settle to the bottom of the bottle, and then perform aseptic operation in the ultra-clean bench, pour out about 75% of the supernatant of the fermentation broth that the previous batch of fermentation has completed, and then pour it into The same volume of fresh culture medium is used for the next batch of fermentation. Pay attention to be careful during the pouring process, and do not sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com