Anti-degradation antibacterial biological coating, and preparation method and application thereof

A bio-coating, anti-degradation technology, applied in coatings, metal material coating technology, medical science, etc., can solve the problem that Ti coatings do not have biological activity, long-term stability needs to be improved, and coatings do not have antibacterial properties and other issues, to achieve the effect of excellent biological activity and biocompatibility, good resistance to degradation, and obvious antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Preparation of Ca by sol-gel method 2 ZnSi 2 o 7 powder

[0024] Tetraethyl orthosilicate (TEOS), ethanol (C 2 h 5 OH), 2M nitric acid (HNO 3 ) according to the molar ratio of 1:8:0.16, after stirring at room temperature for 30 minutes, the pH value of the solution was about 1; adding Zn(NO 3 ) 2 , Ca(NO 3 ) 2 powder, where Zn(NO 3 ) 2 , Ca(NO 3 ) 2 , TEOS molar ratio is 0.5:1:1, stirred at room temperature for 5 hours to obtain a clear solution; 60 ° C for one day to obtain a wet gel; 120 ° C for two days to obtain a dry gel; 1300 ° C for 1 hour to obtain Ca 2 ZnSi 2 o 7 Powder; pass through a 80-mesh sieve, dry at 100-120°C, and set aside. 【References: Ceramics International, 2005(31), 27-31】

[0025] B. Preparation of Ca by plasma spraying technology 2 ZnSi 2 o 7 coating

[0026] After the surface of pure titanium or Ti-6Al-4V alloy is sandblasted or sanded, ultrasonically 1-2 times in absolute ethanol solution, 3-5 minutes each time, and then ...

Embodiment 2

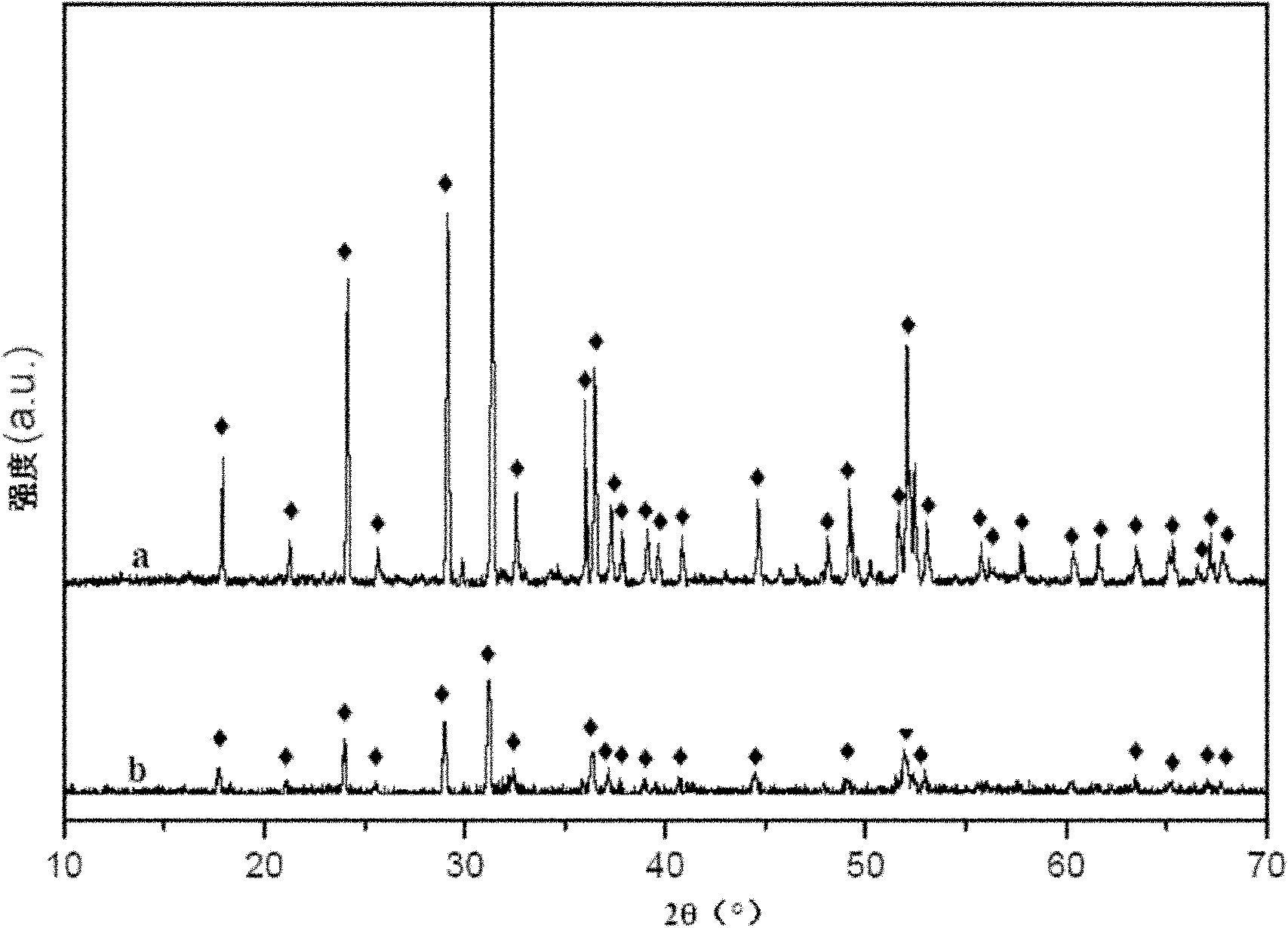

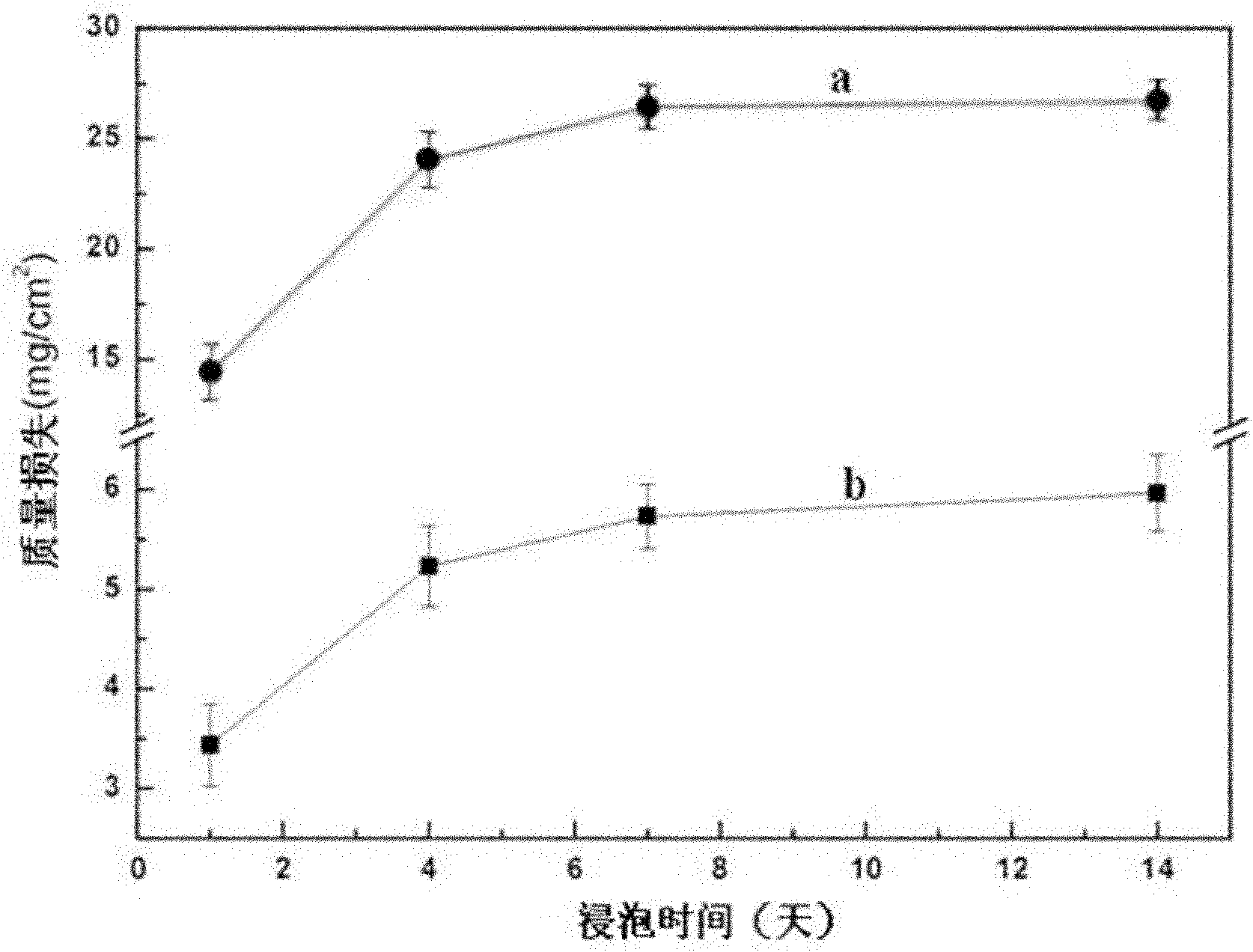

[0030] Example 2: Ca 2 ZnSi 2 o 7 Degradation resistance test of coating

[0031] Ca 2 ZnSi 2 o 7 coating with zinc-free Ca 2 SiO 4 The coatings were respectively soaked in Tris-HCl buffer solution, and the mass loss per unit area of the coatings was compared with time.

[0032] The result is as image 3 shown by image 3 Visible: soaking day 1, Ca 2 SiO 4Coating mass loss per unit area up to 15mg / cm 2 , while Ca 2 ZnSi 2 o 7 The coating is less than 3.5mg / cm 2 , significantly lower than the former; after soaking for 14 days, Ca 2 ZnSi 2 o 7 The mass loss per unit area of the coating is less than 6mg / cm 2 , while Ca 2 SiO 4 Coating exceeds 25mg / cm 2 . By comparison, it can be known that doping Zn into calcium silicate-based ceramics synthesizes Ca 2 ZnSi 2 o 7 Can improve the degradability of calcium silicate based coatings.

Embodiment 3

[0033] Example 3: Ca 2 ZnSi 2 o 7 Antibacterial test of coating

[0034] The antibacterial performance of the material was quantitatively detected by the oscillation method: the standard Staphylococcus aureus was used as the test strain; the strain was inoculated on the surface of nutrient agar, and cultivated in an incubator for 18 hours; with reference to the bacterial standard turbidimetric tube, diluted to 2 × 10 8 Bacteria / ml, serially diluted 10 times to 10 -2 Bacterial solution with high concentration; after high-temperature sterilization, in a conical flask filled with 20ml of PBS, pure Ti (control piece) with a diameter of 16mm and a thickness of 2mm, Ca 2 ZnSi 2 o 7 4 coated discs each; add 0.2ml bacterial solution to the Erlenmeyer flask, shake at constant temperature for 18h. Take the liquid in 0.5ml Erlenmeyer flask respectively, carry out 10 -2 、10 -3 After dilution, 0.2ml each was inoculated into nutrient agar and cultured for 48h.

[0035] Figure 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com