Preparation method and application of silicon rubber/collagen-based porous skin scaffold material

A technology of scaffold material and silicone rubber, which is applied in the field of composite porous scaffold and its preparation, can solve the problems of difficult to control the pore size, unfavorable enzymatic stability of materials, and inappropriate pore size, so as to improve hydrophilicity and improve Biocompatibility, effect of securing material stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: In this example, ammonia plasma modified silicone rubber is selected, and the collagen solution is directly coated, and the dehydrating agent is a mixture of EDC / NHS. The specific steps are as follows:

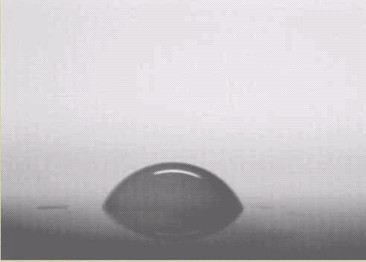

[0031] The first step, plasma modification of the surface of silicone rubber: place the silicone rubber film in the plasma surface treatment instrument, open the ammonia gas valve, start the power at 30 w, and treat for 2 min, see the attached figure 1, the surface hydrophilicity of the modified silicone rubber is improved;

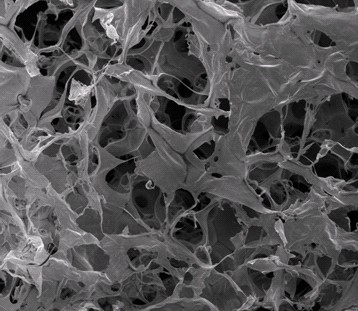

[0032] The second step, the coating of collagen-based biomacromolecules: Prepare 0.6% collagen solution and coat it on the surface of the treated silicone rubber film, use a freeze dryer to extract the solvent (treatment time is 10h), see attached figure 2 , the macroporous structure of the collagen layer can be seen clearly from the scanning electron microscope;

[0033] The third step, the cross-linking of the collagen layer: put the...

Embodiment 2

[0035] Embodiment 2: the present embodiment selects oxygen plasma modified silicone rubber, and directly coats the mixed solution of collagen and chitosan, and dehydrating agent selects the mixture of EDC / NHS, and concrete steps are as follows:

[0036] In the first step, the silicone rubber film is subjected to plasma treatment: place the silicone film in a plasma surface treatment instrument, open the oxygen valve, start the power at 30w, and treat for 10 minutes;

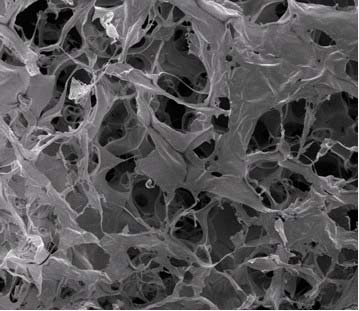

[0037] The second step, the coating of collagen-based biomacromolecules: prepare a 1.0% mixed solution of collagen and chitosan (the mass ratio of collagen / chitosan is 6:4), and coat it on the treated silicon On the surface of the rubber film, use a freeze dryer to extract the solvent (treatment time is 12 hours);

[0038] The third step, the cross-linking of the collagen layer: put the lyophilized silicone rubber / collagen-based porous scaffold into ethanol / H containing 100mM EDC / NHS (molar ratio 1 / 1) 2 O volume...

Embodiment 3

[0040] Embodiment 3: In this embodiment, hydrazine gas plasma modified silicone rubber is selected, and the collagen solution is directly coated, and the dehydrating agent is DMTMM, and the specific steps are as follows:

[0041] In the first step, the silicone rubber film is subjected to plasma treatment: the obtained silicone film is placed in a plasma surface treatment instrument, the hydrazine gas valve is opened, the starting power is 60w, and the treatment is 6 minutes;

[0042] The second part, the coating of collagen-based biomacromolecules: prepare 1.0% collagen solution, and coat it on the surface of the treated silicone rubber film, use a freeze dryer to extract the solvent, (treatment time is 12h);

[0043] The third step, cross-linking of the collagen layer: put the lyophilized silicone rubber / collagen-based porous scaffold into ethanol / HO containing 100mM DMTMM 2 O volume ratio is in the mixed solvent of 7 / 3, after reacting at room temperature for 6 hours, soak a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com