Method for comprehensive exploitation and utilization of silicon, magnesium, iron, and nickel in laterite-nickel ore

A technology of lateritic nickel ore and roasting method, which is applied in the direction of nickel oxide/nickel hydroxide, magnesium oxide, iron oxide, etc., can solve the problems that organic acids cannot be recycled, affect the process flow, and the production cycle is long, etc., and achieve high added value The effect of comprehensive utilization, simple process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

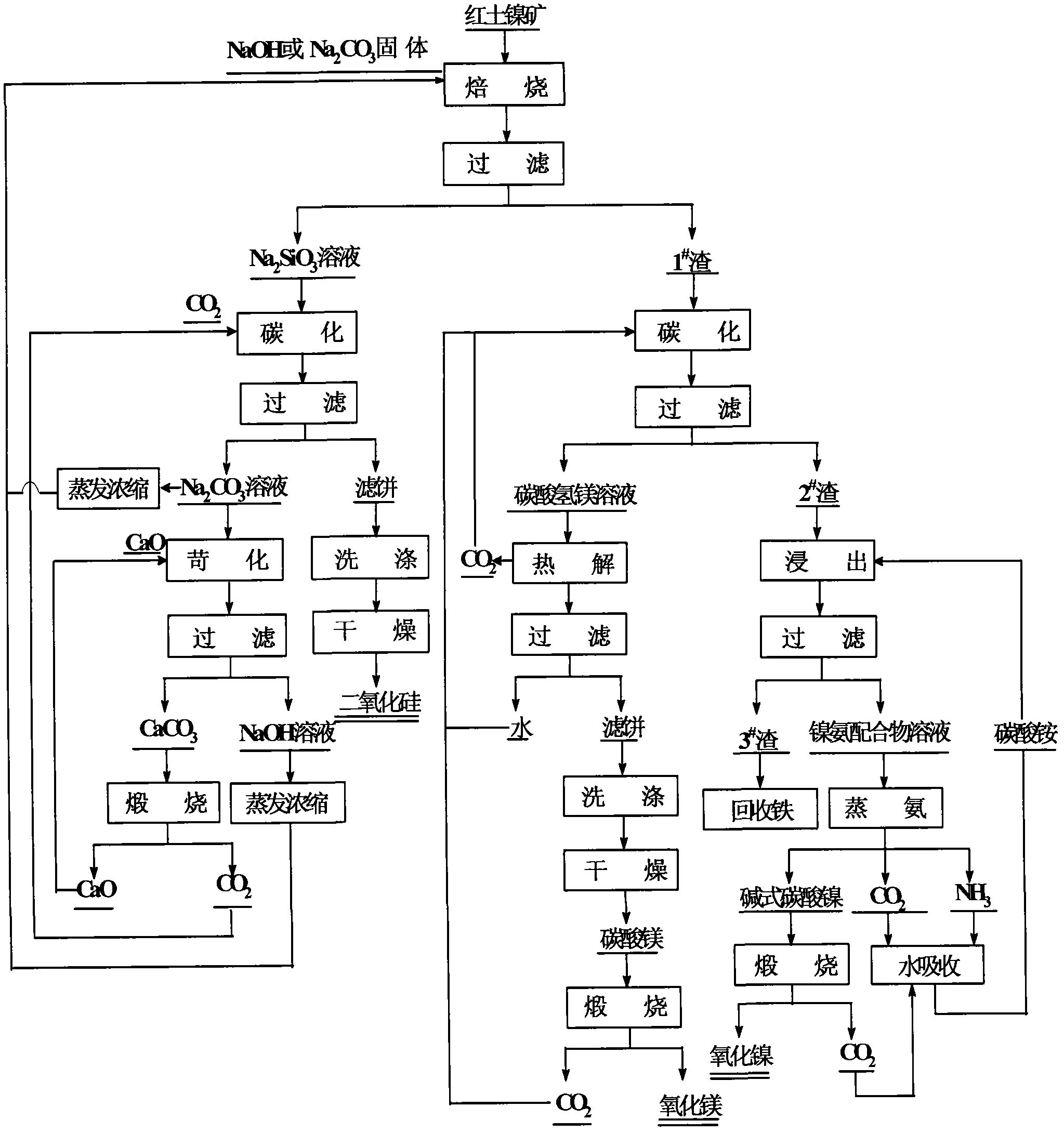

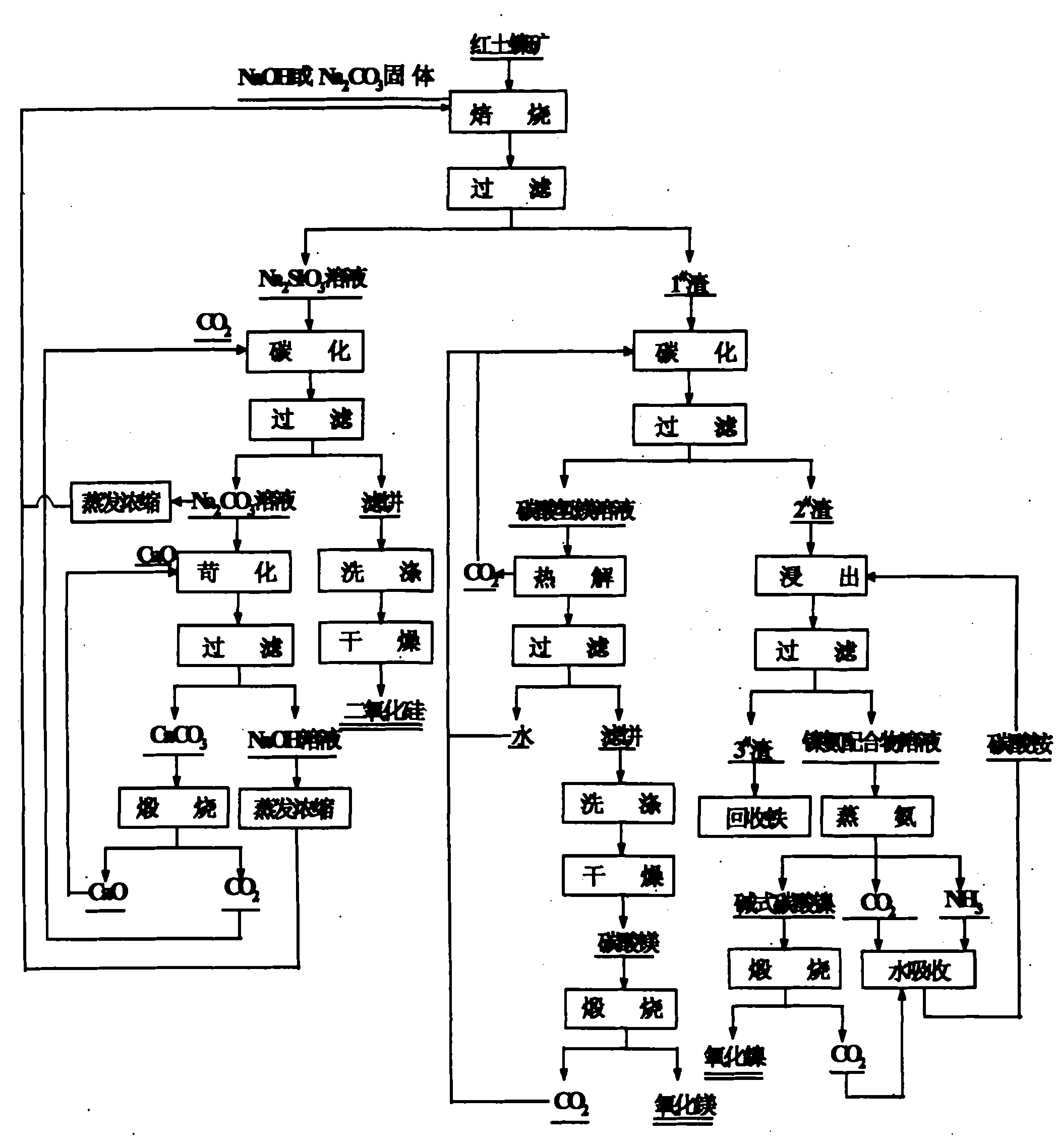

Method used

Image

Examples

Embodiment 1

[0044] The composition of the laterite nickel ore used is: NiO 0.91%, SiO 2 38.74%, MgO 22.53%, Fe 2 o 3 19.82%, Al 2 o 3 4.65%, CaO 0.62%, Cr 2 o 3 0.55%, other impurities 0.78%, loss on ignition 11.4%.

[0045] Mix the laterite nickel ore that is ground to below 80 μm with solid NaOH at a mass ratio of 1:3, roast at 500°C for 4 hours, then stop heating, and when the temperature is lowered to 120°C, take out the clinker, add 4 times the volume of water, and bake at 85°C After boiling and dissolving for 40 minutes at ℃, filter, the filtrate is sodium silicate solution, and the filter cake is 1 # scum.

[0046] Heat the sodium silicate solution to 80°C, under the condition of stirring, pass carbon dioxide gas at a flow rate of 100ml / min, first adjust the pH to 13, filter and separate, remove the silica precipitate with high impurity content, and then continue to pass Carbon dioxide was added to adjust the pH value of the solution to 9, and filtered to obtain a sodium ca...

Embodiment 2

[0051] The composition of the laterite nickel ore used is: NiO 1.03%, SiO 2 40.57%, MgO 20.31%, Fe 2 o 3 18.66%, Al 2 o 3 3.87%, CaO 0.68%, Cr 2 o 3 0.52%, other impurities 0.86%, loss on ignition 13.65%.

[0052] The laterite nickel ore that is ground to below 80μm and solid Na 2 CO 3 Mix according to the mass ratio of 1:3, roast at 1200°C for 3 hours, then stop heating, when the temperature drops to 100°C, take out the clinker, add 3 times the volume of water, boil and dissolve at 80°C for 60min, then filter, the filtrate is sodium silicate solution, filter cake is 1 # scum. The carbon dioxide gas generated during the roasting process is collected as raw material for the carbonization process.

[0053] Heat the sodium silicate solution to 85°C, under stirring conditions, pass in carbon dioxide gas at a flow rate of 150ml / min, first adjust the pH to 13, filter and separate, remove the silica precipitate with high impurity content, and then continue to pass in carbo...

Embodiment 3

[0058] The composition of the laterite nickel ore used is: NiO 1.21%, SiO 2 36.88%, MgO 24.63%, Fe 2 o 3 21.95%, Al 2 o 3 5.05%, CaO 0.57%, Cr 2 o 3 0.61%, other impurities 0.46%, loss on ignition 12.05%.

[0059] Mix the laterite nickel ore that is ground below 80 μm with solid NaOH at a mass ratio of 1:4, roast at 475°C for 5 hours, then stop heating, and when the temperature is lowered to 100°C, take out the clinker, add 3 times the volume of water, and After boiling at 80°C for 60 minutes, filter, the filtrate is sodium silicate solution, and the filter cake is 1 # scum.

[0060] Heat the sodium silicate solution to 90°C, under the condition of stirring strength, pass carbon dioxide gas at a flow rate of 100ml / min, first adjust the pH to 13, filter and separate, remove the silica precipitate with high impurity content, and then continue Add carbon dioxide until the pH value of the solution drops to 9, and filter to obtain sodium carbonate solution and filter cake. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com