Method for preparing graphene material based on chemical deposition

A chemical deposition method and chemical deposition technology, which are applied in the field of batch preparation of graphene, can solve the problems of many surface defects of graphene materials, unable to realize batch preparation, and fail to realize batch production, etc., and achieve fewer defects, complete crystal structure, Realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

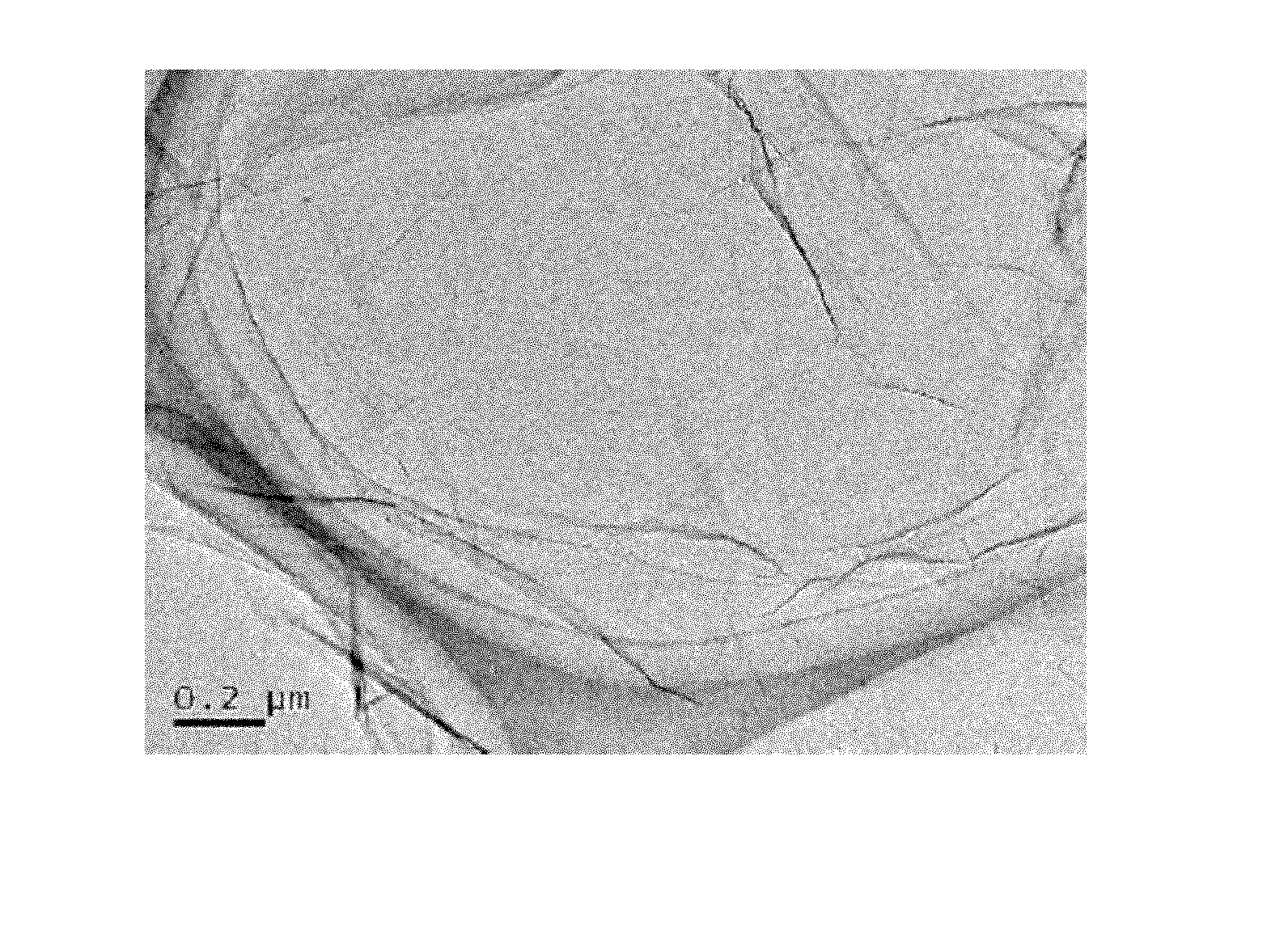

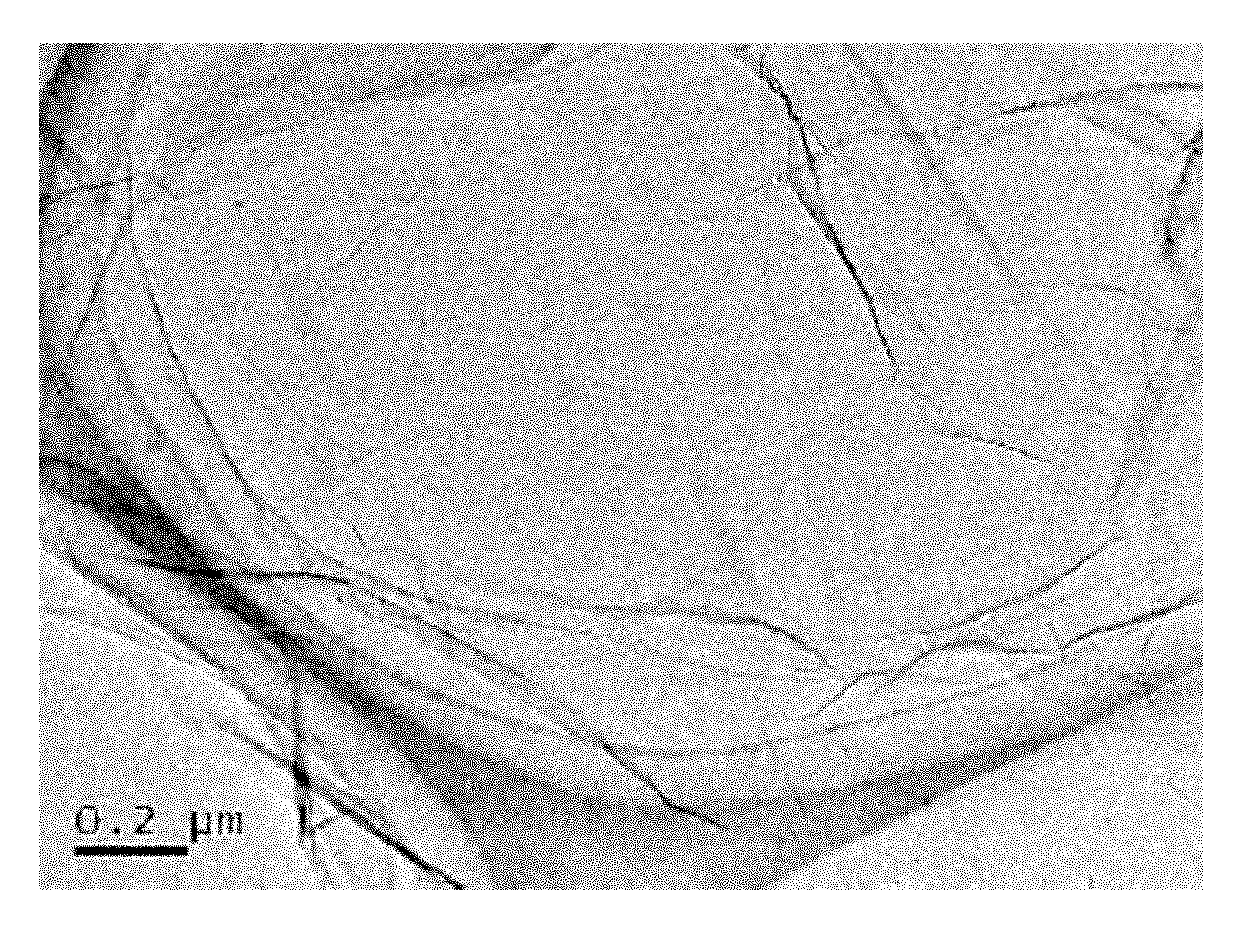

Image

Examples

Embodiment 1

[0022] With the quartz substrate as the substrate, put it into the reactor, raise the temperature to 800 °C under the nitrogen atmosphere, and put the CoCl 2 Mix it with polypropylene and acetone at a ratio of 0.001:1:1 and pass it into the reactor for 30 minutes. After cooling, take out the substrate, put it in dilute hydrochloric acid and ultrasonically wash it thoroughly, filter and wash it until neutral, and dry the obtained graphene material.

Embodiment 2

[0024] Based on the ceramic ball whose main composition is zirconia, put it into the reactor, raise the temperature to 1000℃ under the argon atmosphere, and put the NiCl 2 Mix it with polyethylene and ethyl acetate in a ratio of 10:1:100 and pass it into the reactor for 2 minutes. After cooling, take out the substrate, put it in dilute hydrochloric acid and ultrasonically wash it thoroughly, filter and wash it until neutral, and dry the obtained graphene. Material.

Embodiment 3

[0026] Based on the ceramic ball whose main composition is Al2O3, it is put into the reactor, and the temperature is raised to 500 ° C under the helium atmosphere, and the FeSO 4 Mix it with polystyrene and benzene at a ratio of 0.01:1:50 and pass it into the reactor for 1 hour of reaction. After cooling, take out the substrate, place it in dilute hydrochloric acid and ultrasonically wash it thoroughly, filter and wash it until neutral, and dry the obtained graphene material. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com