High temperature heat barrier material, coating, molded product and application thereof

A thermal barrier and warming technology, which is applied in the field of high-temperature thermal barrier materials and high-temperature-resistant thermal barrier materials, can solve the problems of porosity of products that are easy to absorb moisture and fall off, difficult to meet complex shapes, and high thermal conductivity of the inner layer, and achieve energy-saving effects Obvious, avoid extension, high heat reflectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: High Temperature Thermal Barrier Material Formulation

[0060] The formula 1 of the high-temperature thermal barrier material is shown in Table 1 below.

[0061] Table 1 High temperature thermal barrier material formula 1

[0062] raw material name Specifications (mm) content(%) Actual weighed weight (kg) Remark High alumina bauxite clinker 0.07 27.0 1.35 clay 0.04 6.0 0.30 Silica powder 0.037 5.5 0.28 boric acid 0.09 5.5 0.28 sodium tripolyphosphate 0.037 1.0 0.05 Silicon carbide 0.03 17.0 0.85 polyacrylamide 0.09 1.0 0.05 F01 solution 28.5 1.43 Deionized water Level 3 test water 8.5 0.43 Total 100 5.00

[0063] Note: "F01 solution" in the table refers to one of the series products "F00 solution" produced by Shilin (Luohe) Metallurgical Equipment Company. "F00 solution" component materials are selected from a group of one ...

Embodiment 2

[0069] Embodiment 2: slurry production process steps

[0070] According to the actual weight of formula 1 or formula 2 in Example 1, take the powder part of various raw materials; add it to the test ball mill, and then add zirconia balls with a diameter of 20mm, and discharge after 2 hours of electrified ball milling. The mixed powder specification is ≥400 mesh.

[0071] According to the mixed powder, one of the corresponding "F00 solutions", and water, weigh the amount of the formula and pour it into a glass beaker, stir and mix with a small medical adjustable stirrer for 30 minutes to form a high-temperature heat barrier slurry, and then put it into storage The container is ready to use.

[0072] The specific steps of making the slurry are as follows:

[0073] 1. Weigh the weight of the main inorganic metal salt or organometallic compound solution;

[0074] 2. Weigh out the weight of various additives and mix them;

[0075]3. Mix the additive with the main inorganic meta...

Embodiment 3

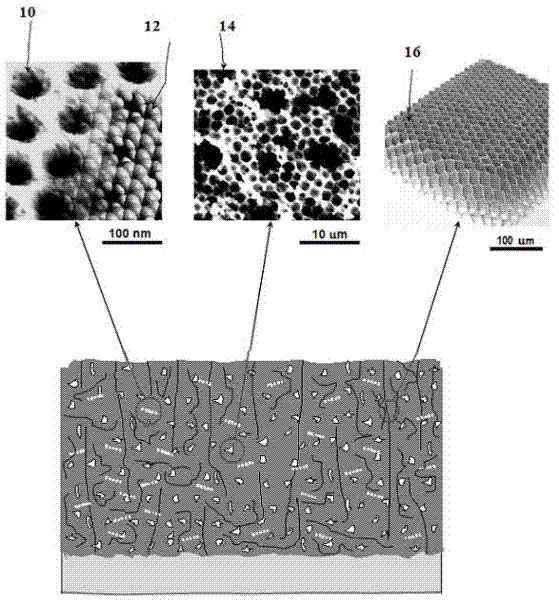

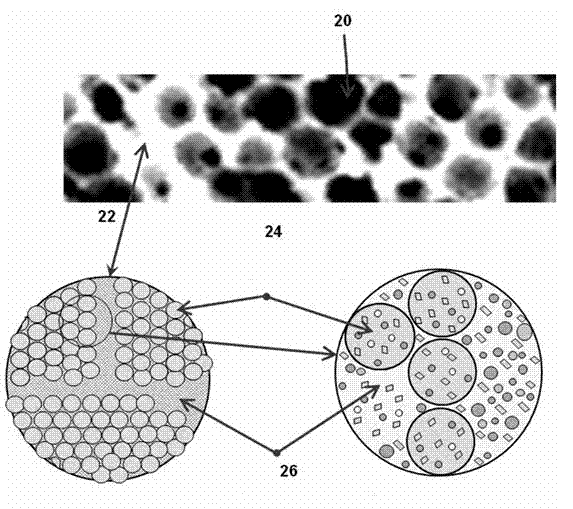

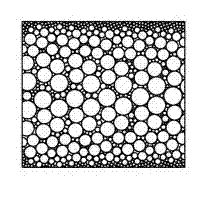

[0083] Embodiment 3: make porous (honeycomb) nano-coating

[0084] The slurry of Example 2 was painted on the surface of a 1 square foot ceramic coupon with a thickness of 2 inches. Ceramic test pieces were cleaned with acetone and then allowed to dry. Put the cleaned test piece into the muffle furnace and heat it to 400 °C. After removal from the muffle furnace, brush a thin layer of slurry on the hot surface of the ceramic coupon. After cooling, several thin layers of slurry are painted on it in order, and a porous (honeycomb) nano-coating can be formed after drying.

[0085] Next, the coated surface was sectioned with a sample cutter. Microstructural analysis of cross-sectional samples is carried out by appropriate metallographic procedures. SEM micrographs of cross-sectional samples as Figure 4 shown. 44 in the figure refers to a smooth surface with porosity; 40 refers to a good bonding interface between the coating and the substrate; 42 refers to the internal coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com