Composite premixed feed for reducing heavy metal residue in animal products as well as preparation method and application thereof

A technology for pre-mixed feed and animal products, applied in animal feed, animal feed, application, etc., can solve problems such as inability to effectively reduce heavy metal residues, single action target, and influence on the metabolism of essential trace elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

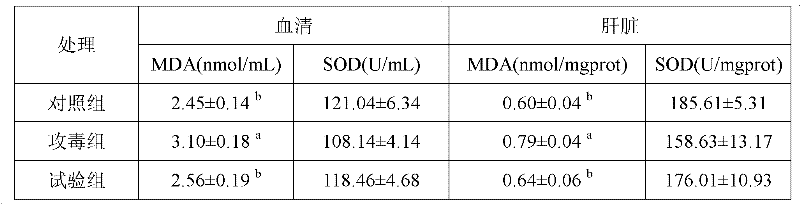

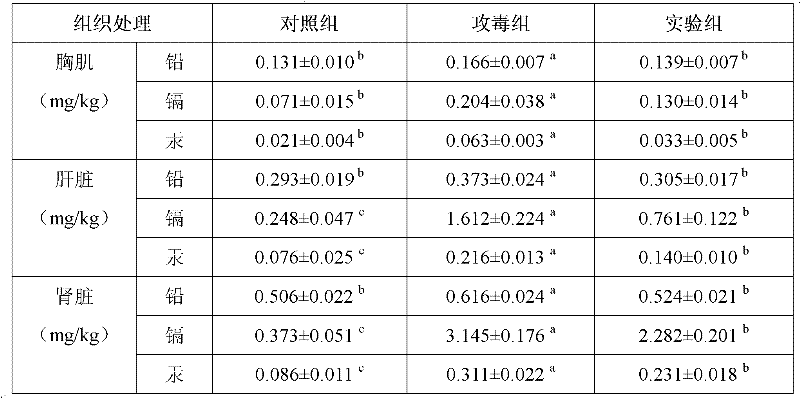

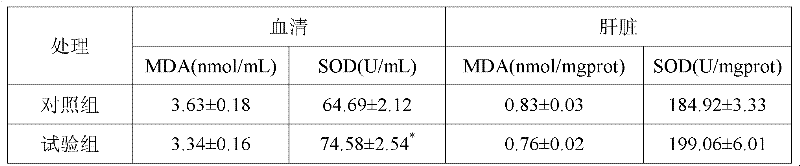

Examples

Embodiment 1

[0034] Get 20g chitosan, add 400g 3% (volume fraction) acetic acid solution, fully stir to make chitosan dissolve completely, adjust the pH to 5.5, stir at a constant speed under the condition of 50 ℃, directly add 100g of attapulgite clay, at 60 Stir at ℃ for 4 hours, centrifuge to separate the precipitate, wash twice with distilled water, filter with suction, dry at 70 ℃, pulverize, and pass through a 200-mesh sieve to obtain chitosan-attapulgite clay composite A. The chitosan used is oligomeric chitosan produced by Zhejiang Jiaxing Kerui Biotechnology Co., Ltd. by physical irradiation degradation method. Its relative molecular mass ranges from 5000 to 50000 Daltons, the degree of deacetylation is greater than 85%, and the particle size is less than 25 microns. Attapulgite clay is an acid-modified product provided by a company in Xuyi, Jiangsu, which contains more than 70% attapulgite.

[0035] In vitro simulated intestinal adsorption test was carried out on the product. Th...

Embodiment 2

[0037] Composite premixed feed quality of the present invention is calculated in 100 parts, obtains the premixed feed that reduces heavy metal residues in animal products according to the ratio of mass and number as described below and the preparation method: 0.5 part of chitosan, 0.00033 parts of selenium (derived from methionine selenium) and 0.5 parts of vitamin C and 3.3 parts of attapulgite clay are mixed step by step in a high-efficiency mixer to obtain mixture 1; the remaining 39 parts of attapulgite clay, 16.7 parts of zeolite, 10 parts of bentonite, 6.7 parts of yeast , 13.3 parts of chitosan-attapulgite clay compound and 10 parts of ultrafine pulverized tea powder are mixed in a high-efficiency mixer to obtain mixture 2; add mixture 2 and mixture 1 in sequence, and mix 2.5 After 10 minutes, the resulting mixture is packaged, which is a compound premixed feed for chickens that reduces heavy metal residues in animal products, and is recorded as premixed feed product B. ...

Embodiment 3

[0039] The compound premixed feed quality of the present invention is calculated in 100 parts, obtains the premixed feed that reduces animal product heavy metal residue by the mass fraction ratio and preparation method described below: 0.6 part of chitosan, 0.0005 part of selenium (derived from methionine selenium) and 0.75 parts of vitamin C and 3.15 parts of attapulgite clay were mixed step by step in a high-efficiency mixer to obtain mixture 1; the remaining 43 parts of attapulgite clay, 15 parts of zeolite, 10 parts of sepiolite, 7.5 1 part of yeast, 10 parts of chitosan-attapulgite clay compound and 10 parts of superfine pulverized tea powder are mixed in a high-efficiency mixer to obtain mixture 2; After mixing for 2.5 minutes, the resulting mixture is packaged. In order to reduce the compound premixed feed for pigs with heavy metal residues in animal products, it is recorded as premixed feed product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com