Synthesis method of gamma-thiopropyl trimethoxy silane

A technology of mercaptopropyltrimethoxysilane and chloropropyltrimethoxysilane, which is applied in the field of synthesis of γ-mercaptopropyltrimethoxysilane, can solve problems such as uneven distribution, many by-products, and slow reaction. To achieve the effect of strengthening the uniformity of reaction, sufficient reaction and strengthening the uniformity of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

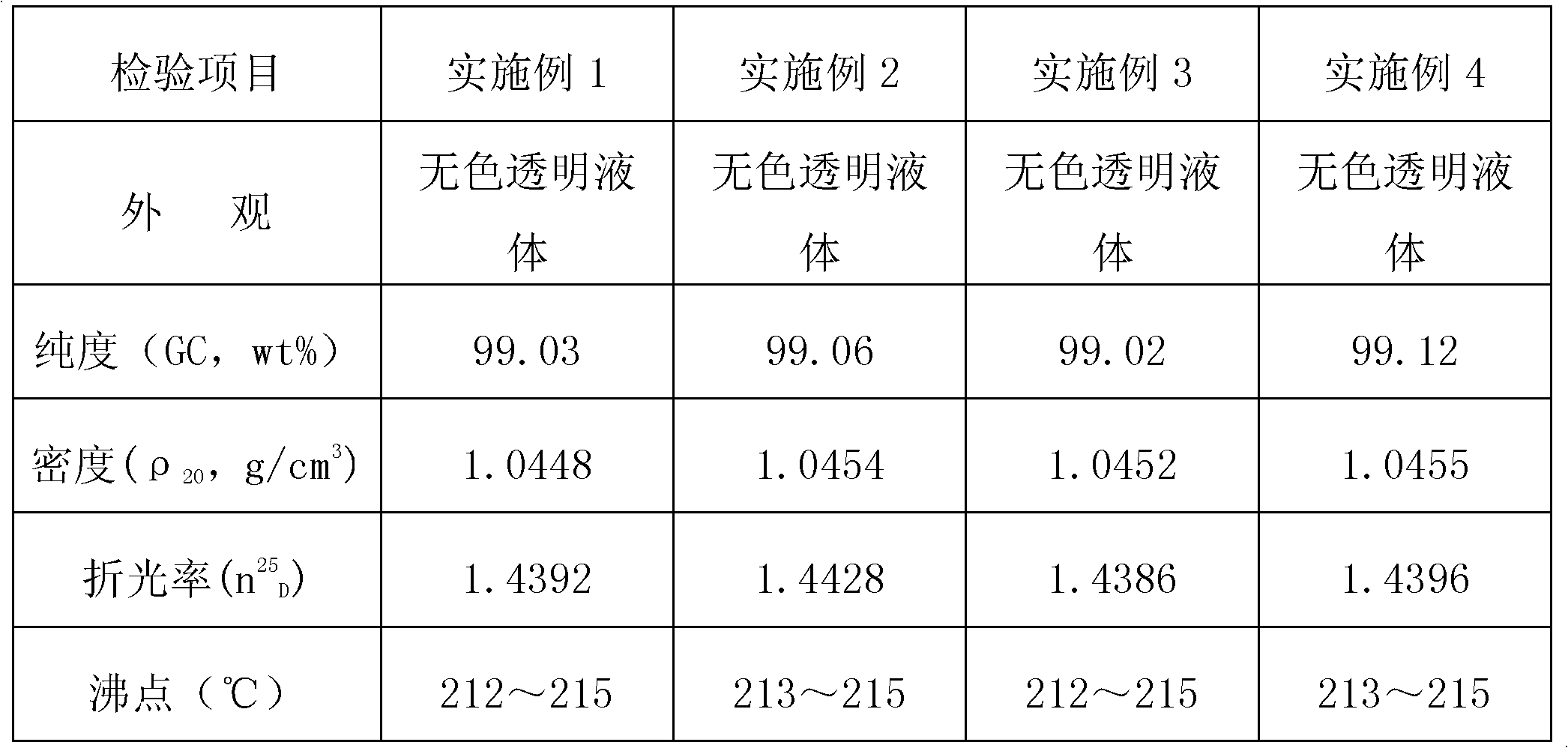

Examples

Embodiment 1

[0057] (1) 140Kg solid industrial product NaHS is added to the dissolving kettle, then add 137Kg water and stir and dissolve for 20 minutes, the stirring speed is 67 rpm, after dissolving completely, add 30wt% hydrochloric acid 5Kg, citric acid 4Kg and sodium citrate 2.5Kg, Stir for 25 minutes to adjust the pH value below 7.0, and then put it into the high tank.

[0058] (2) γ-chloropropyltrimethoxysilane 300Kg, ethanol 8Kg, phase transfer catalyst dodecyltrimethylammonium chloride 7Kg and tetrabutylammonium bromide 8.5Kg, stabilizer thiaphenazine 1.5Kg and propylene glycol 0.8Kg, stir for 25 minutes to mix evenly, and then pour into the high tank.

[0059] (3) The synthesis reactor is evacuated to a stable pressure of 0.98Mpa, kept for 12 minutes, and the volume ratio of 1:0.35 N 2 and CO 2 The mixed gas, until the pressure in the reactor is stable at 0.1MPa, stop feeding N 2 and CO 2 , turn on the plunger pump, open the jacket steam valve at the same time, adjust the tem...

Embodiment 2

[0062] (1) Add 160Kg of solid industrial product NaHS to the dissolving kettle, then add 145Kg of water and stir and dissolve for 30 minutes at a stirring speed of 80 rpm. After the dissolution is complete, add 5.5Kg of 30wt% hydrochloric acid, 5Kg of citric acid and 3.2Kg of sodium citrate , Stir for 25 minutes to adjust the pH value below 7.0, and then put it into the high tank.

[0063] (2) γ-chloropropyltrimethoxysilane 320Kg, ethanol 9.5Kg, phase transfer catalyst dodecyltrimethylammonium chloride 7.5Kg and tetrabutylammonium bromide 9.5Kg, stabilizer thiaphenazine 1.6Kg With 0.9Kg of propylene glycol, stir for 25 minutes to mix evenly, then pour into the head tank.

[0064] (3) The synthesis reactor is evacuated to a stable pressure of 0.96Mpa, and kept for 15 minutes, and the volume ratio of 1:0.37 N 2 and CO 2 The mixed gas, until the pressure in the reactor is stable at 0.11MPa, stop feeding N 2 and CO 2 , turn on the plunger pump, open the jacket steam valve at t...

Embodiment 3

[0067] (1) Add 150Kg of solid industrial product NaHS to the dissolving kettle, then add 160Kg of water and stir and dissolve for 30 minutes at a stirring speed of 90 rpm. After the dissolution is complete, add 30wt% hydrochloric acid 6Kg, citric acid 5.5Kg and sodium citrate 3.5KgpH Conditioner, stir for 30 minutes, then pour into overhead tank.

[0068] (2) γ-chloropropyltrimethoxysilane 350Kg, ethanol 11Kg, phase transfer catalyst dodecyltrimethylammonium chloride 8.2Kg and tetrabutylammonium bromide 10.5Kg, stabilizer thiaphenazine 1.7Kg and Propylene glycol 1.2Kg, stir for 30 minutes to mix evenly, and then put it into the head tank.

[0069] (3) The synthesis reactor is evacuated to a stable pressure of 0.97Mpa, kept for 10 minutes, and the volume ratio of 1:0.4 N 2 and CO 2 The mixed gas, until the pressure in the reactor is stable at 0.12MPa, stop feeding N 2 and CO 2 , turn on the plunger pump, open the jacket steam valve at the same time, adjust the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com