Catalyst for deeply removing CO at low temperature as well as preparation and activation methods and application thereof

A technology of catalyst and composite catalyst, which is applied in the direction of chemical change purification/separation, nitrogen purification/separation, etc. It can solve the problems of no clear activation method and unclear service life of adsorbed substances, so as to achieve excellent CO removal performance and reduce equipment investment , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

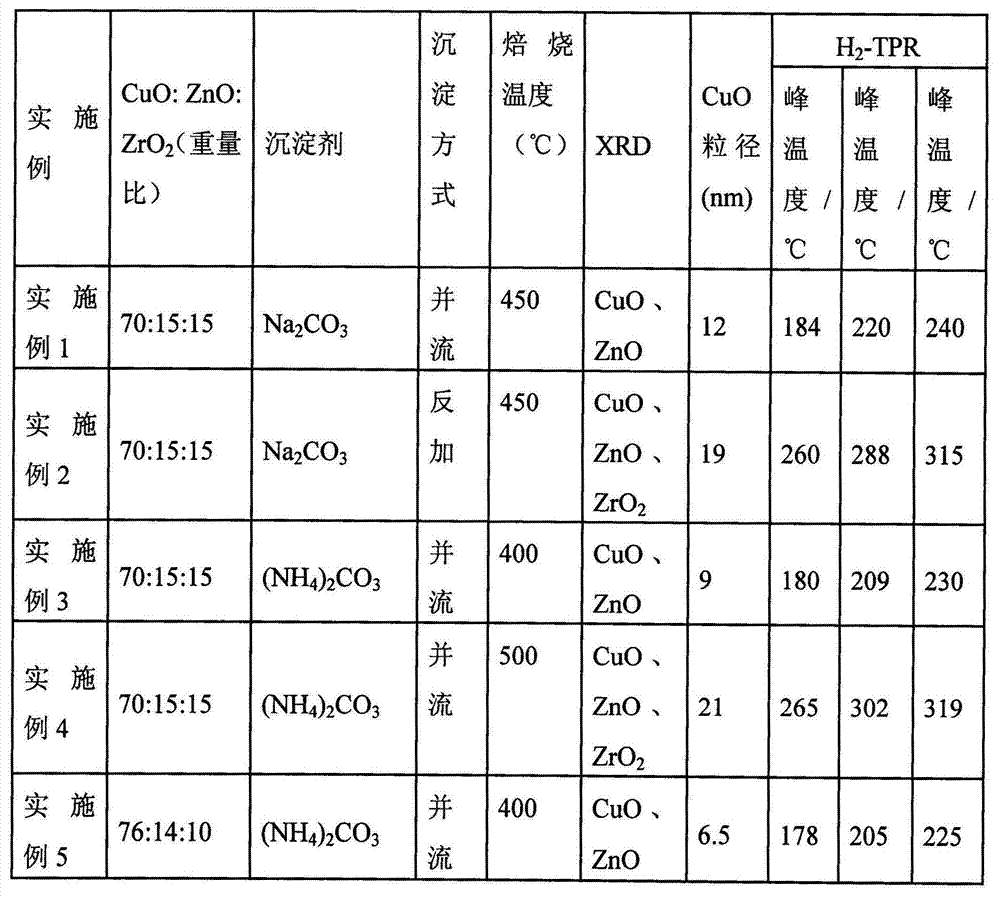

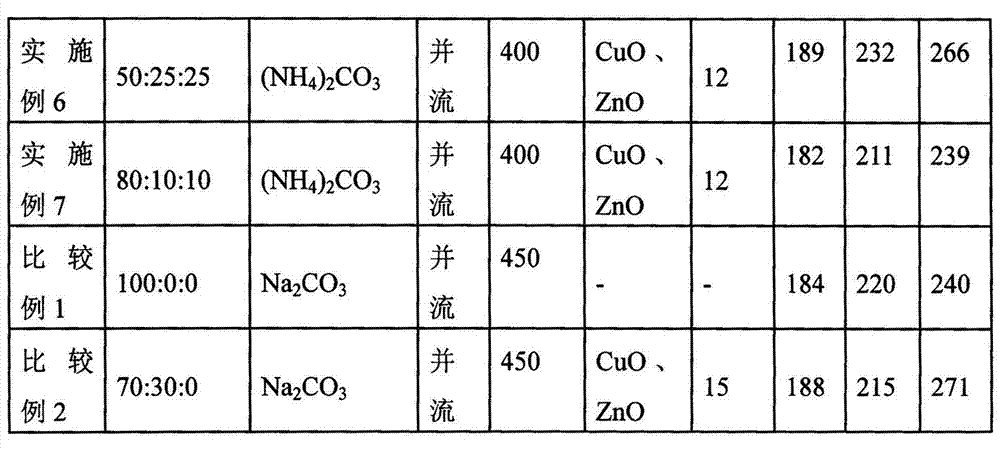

[0044] CuO / ZnO / ZrO 2 Preparation of composite oxide catalyst precursor

[0045] According to the ratio: CuO: ZnO: ZrO 2 =x:y:(1-x-y) Weigh the raw materials, and the values of x and y are percentages by weight, as shown in Table 1.

[0046] Prepare Cu, Zn, Zr metal nitrates into solutions of a certain concentration, and mix them evenly under stirring; through a certain precipitation method, precipitate with ammonium carbonate solution under stirring and a certain temperature, after the precipitation is completed, adjust the pH value of the system ; Aging the obtained catalyst precursor at a certain temperature, fully stirring; taking out the solid product, washing it repeatedly with deionized water at a certain temperature, centrifuging, and placing it in a drying oven at 110°C for overnight drying; at 350-550°C Calcined for 6.0 hours and cooled to room temperature to obtain calcined CuO / ZnO / ZrO 2 Composite oxide products;

[0047] The precipitation methods include co-cu...

Embodiment 8~11

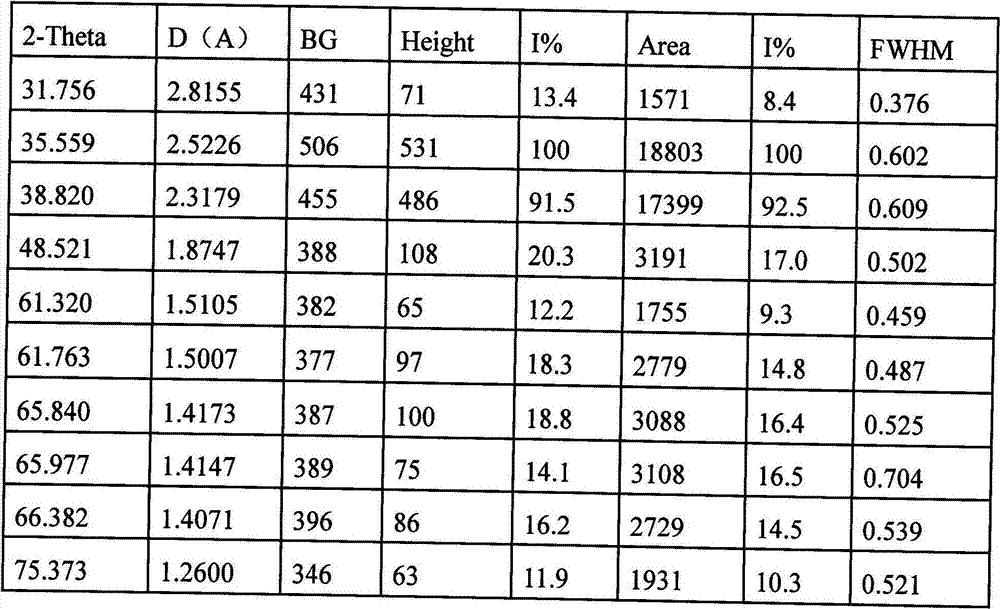

[0060] CuO / ZnO / ZrO 2 Activation of composite oxide catalysts

[0061] After compressing and crushing the composite oxide catalyst prepared in Embodiment 5, sieve molecular sieve particles with a particle size of 80-100 mesh for activation.

[0062] The activation adopts a fixed bed catalytic reaction device, and the reactor is a stainless steel tube. The catalyst prepared in Example 5 is reduced and activated. The process conditions used for activation are: catalyst loading 3mL, activation temperature is 100-200 ° C, and the pressure is normal pressure. Activation time 4h, raw material is 10%H 2 / N 2 , with a volumetric space velocity of 4000 hours -1 . After characterization, the effects of different activation temperatures on the reduction degree of the catalyst are shown in Table 3.

[0063] Table 3 activation results

[0064]

Embodiment 12

[0066] Evaluation of Low Temperature Removal of Trace CO in Hydrocarbons

[0067] A fixed-bed catalytic reaction device is adopted, and the reactor is a stainless steel tube. The catalysts of Examples 8 to 11 are respectively evaluated for CO removal performance. The process conditions used for the evaluation are: the catalyst loading is 3 mL, the reaction temperature is 40 ° C, and the reaction pressure is 3MPa, the raw material is liquid phase propylene containing 20ppm CO, and the liquid phase space velocity is 8.0 hours -1 . After the product was decompressed, it was analyzed online with a helium ion detector GC9560, and the evaluation results are shown in Table 4.

[0068] Table 4 The results of trace CO removal in liquid phase propylene

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com