Preparation method of oil/rosin base liquid calcium-zinc composite stabilizing agent used for PVC (Polyvinyl Chloride)

A technology of compounding heat stabilizer and liquid calcium and zinc, applied in the field of plastic additives, can solve the problem of price fluctuation of stabilizer, and achieve the effects of excellent thermal stability, reduced pollution, good thermal stability and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

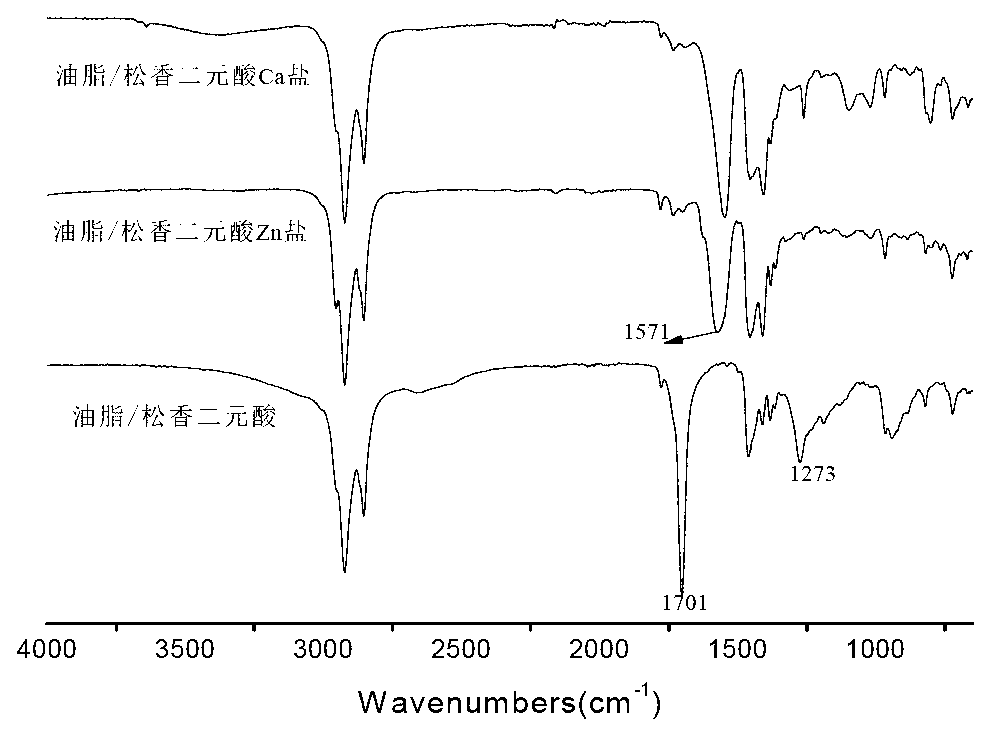

[0030] (1) In an autoclave equipped with a stirring device and a thermometer, add 282g of industrial fatty acid and 302g of rosin, the catalyst aluminum oxide accounts for 4% of the total mass of industrial fatty acid and rosin, and the cocatalyst active clay accounts for 4% of the total mass of industrial fatty acid and rosin 50%, maintain a pressure of 0.5MPa, stir and heat to 200°C, after 6 hours of reaction, stop heating, cool to 80°C; adjust the pH of the system to 7, filter, wash with water, and then distill at 230°C / 1~2mmHg, The unreacted rosin and fatty acid are steamed out, and what remains in the distillation bottle is oil / pine resin-based compound dibasic acid.

[0031] (2) Add 1 mol of oil / pine resin-based compound dibasic acid, propylene glycol methyl ether in an amount of 40% of the mass of oil / pine resin-based compound dibasic acid and 50% of the mass of oil / pine resin-based compound dibasic acid 1, 4-dioxane, after stirring evenly, add 1mol zinc oxide, keep war...

Embodiment 2

[0037] (1) In an autoclave equipped with a stirring device and a thermometer, add 846g of industrial fatty acid and 302g of rosin, the catalyst lithium carbonate accounts for 3% of the total mass of industrial fatty acid and rosin, and the cocatalyst montmorillonite accounts for 3% of the total mass of industrial fatty acid and rosin 30%, maintain a pressure of 0.4MPa, stir and heat to 250°C, after 4 hours of reaction, stop heating, cool to 80°C; adjust the pH of the system to 7, filter, wash with water, and then distill at 250°C / 1~2mmHg, The unreacted rosin and fatty acid are steamed out, and what remains in the distillation bottle is oil / pine resin-based compound dibasic acid.

[0038] (2) Add 1 mol of oil / pine resin-based compound dibasic acid, propylene glycol methyl ether in an amount of 50% of the mass of oil / pine resin-based compound dibasic acid, and 50% of the mass of oil / pine resin-based compound 1,4-Dioxane, after stirring evenly, add 0.95mol zinc oxide, keep it at ...

Embodiment 3

[0042] (1) In an autoclave equipped with a stirring device and a thermometer, add 564g of industrial fatty acid and 302g of rosin. The catalyst strong acidic cation exchange resin accounts for 5% of the total mass of industrial fatty acid and rosin, and the cocatalyst active clay accounts for 5% of the total mass of industrial fatty acid and rosin. 20% of the mass, maintain a pressure of 1MPa, stir and heat to 280°C, after 3 hours of reaction, stop heating, cool to 70°C; adjust the pH of the system to 7, filter, wash with water, and then distill at 280°C / 1~2mmHg , steam out unreacted rosin and fatty acid, and what remains in the distillation bottle is grease / rosin-based compound dibasic acid.

[0043] (2) Add 1 mol of oil / pine resin-based compound dibasic acid, high-boiling point petroleum ether in an amount equal to 50% of the mass of the oil / pine resin-based compound dibasic acid in the reaction bottle, stir evenly, add 0.8 mol of zinc oxide, and heat at 150°C After keeping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com