Phosphate-coated nano-grade lithium iron phosphate cathode material and preparation method thereof

A cathode material, phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as poor kinetic performance, and achieve the effects of cheap raw materials, easy availability of raw materials, and convenient manufacturing process operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to iron, phosphorus, lithium, aluminum molar ratio is 1: 1.05: 1.1: 0.05, take ferric phosphate, lithium carbonate, aluminum phosphate and mix, add to the water-based solvent that contains mass fraction and be 4% PVP ball mill, milling speed is 1500r / min, ball milling 2h. The slurry was transferred to an 80°C drying oven for vacuum drying, and the dried precursor was transferred to an inert atmosphere protection furnace with nitrogen protection, and the temperature was raised to 350°C at a rate of 5°C / min. The heating rate of ℃ / min is raised to 700℃, kept for 18h, and LiAlP is obtained after cooling 2 o 7 Coated Nano LiFePO 4 Lithium-ion battery cathode material.

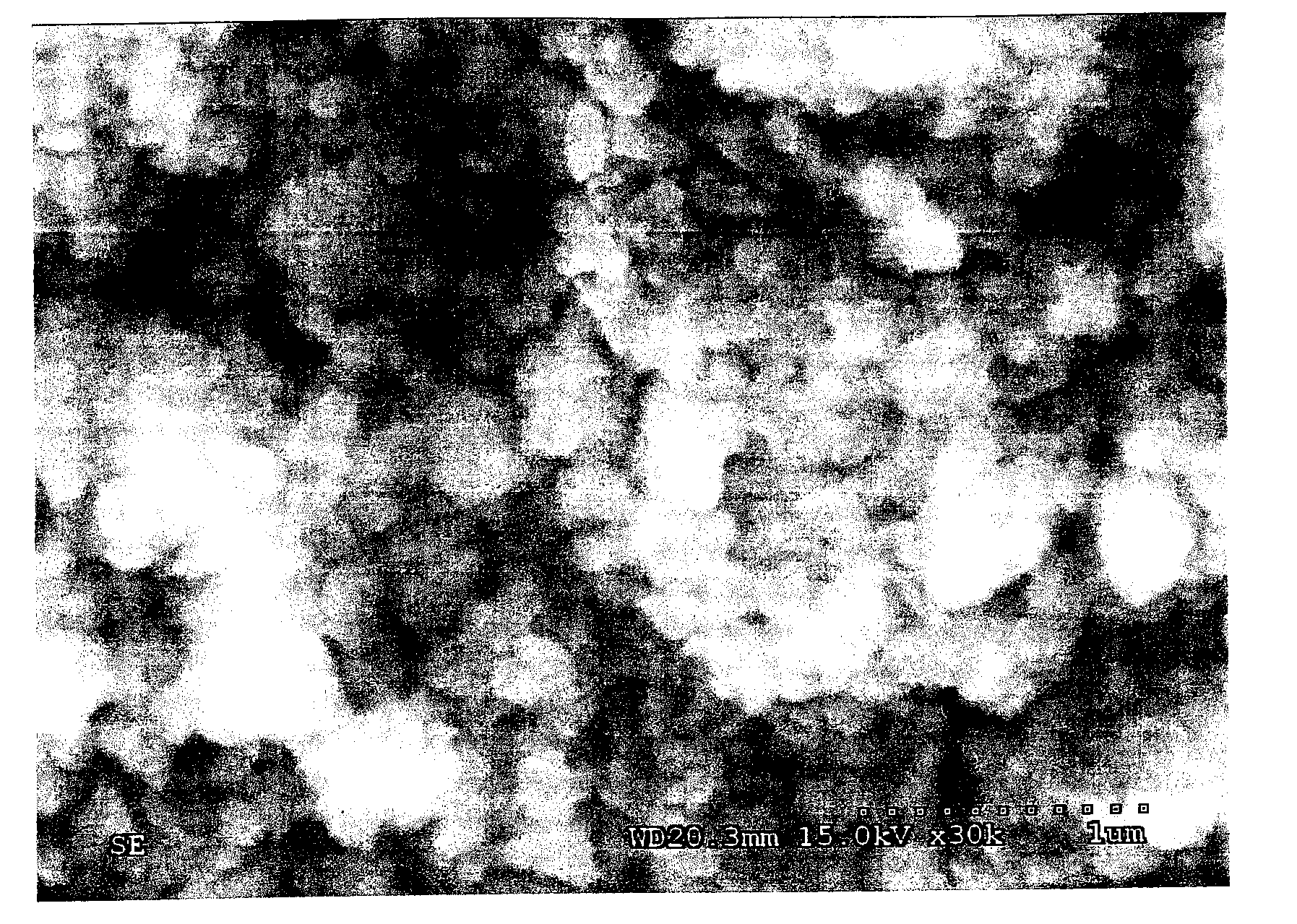

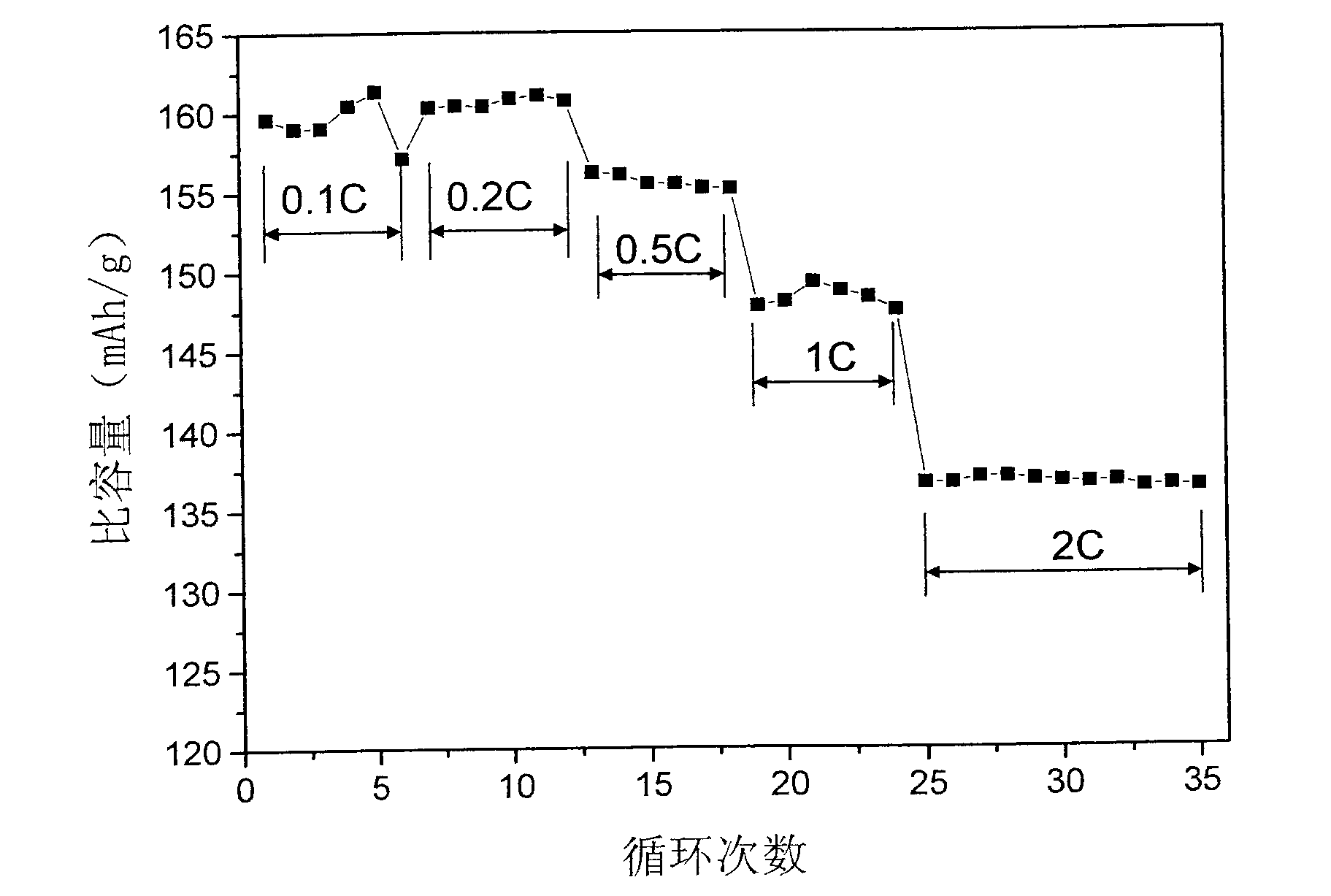

[0018] figure 1 It is a scanning electron microscope picture of the obtained sample. It can be seen from the figure that the obtained sample particles are uniform and fine, and the primary particle is about 100nm. figure 2 is LiAlP obtained by the above method 2 o 7 Coated Nano LiFePO 4 Li...

Embodiment 2

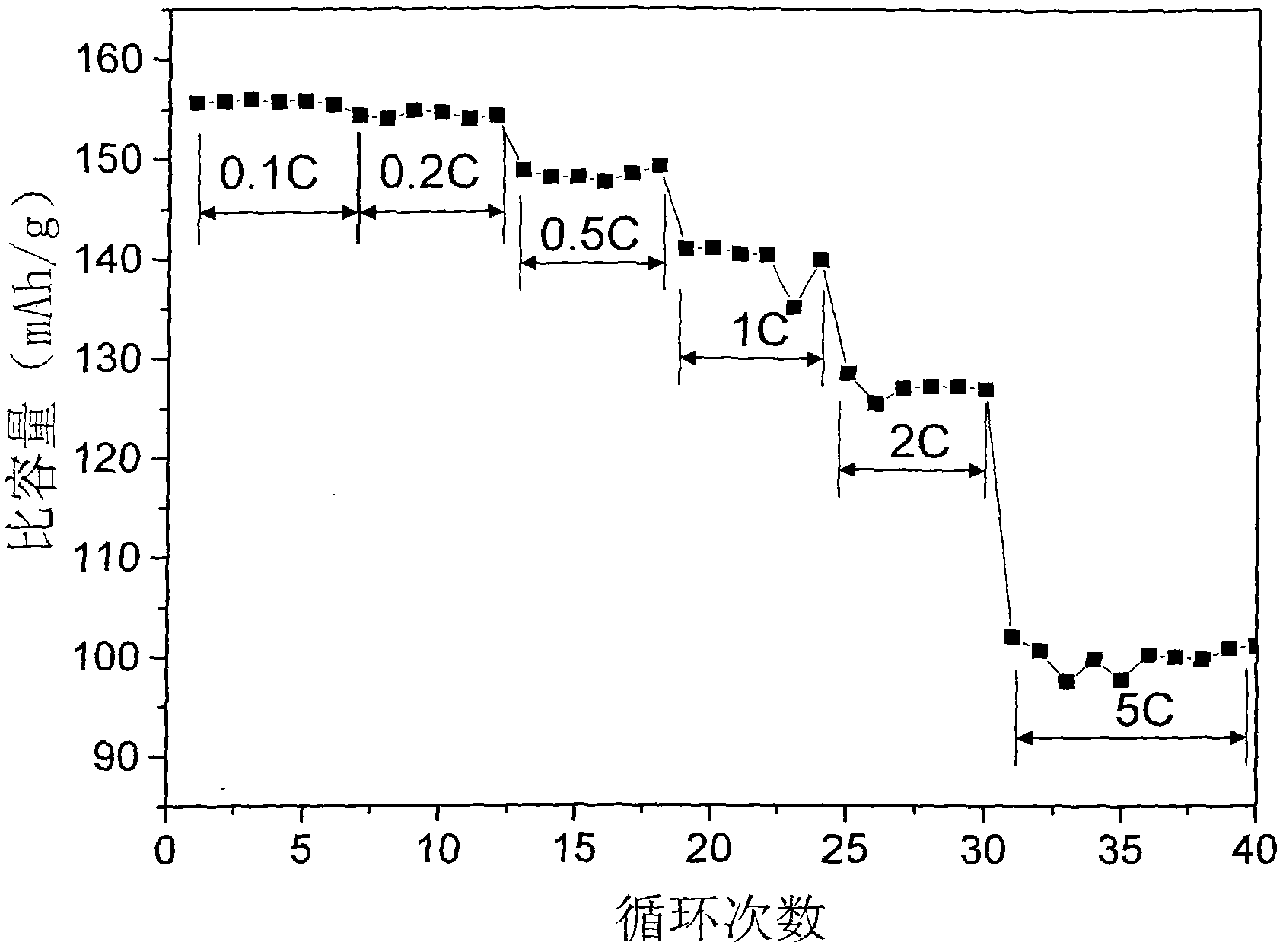

[0020] According to the iron, phosphorus, lithium, aluminum molar ratio of 1:1:1.02:0.01, weigh iron phosphate, lithium carbonate, aluminum oxide (or aluminum acetate, aluminum nitrate) and mix, add to the aqueous solvent containing 3.5% PEG by mass fraction Medium ball milling, the grinding speed is 800r / min, ball milling 10h. The slurry was transferred to an 80°C drying oven for vacuum drying, and the dried precursor was transferred to an inert atmosphere protection furnace with nitrogen protection, and the temperature was raised to 350°C at a rate of 8°C / min. The heating rate of ℃ / min is raised to 710℃, kept for 14h, and LiAlP is obtained after cooling 2 o 7 Coated Nano LiFePO 4 Lithium-ion battery cathode material. image 3 is LiAlP obtained by the above method 2 o 7 Coated Nano LiFePO 4 Lithium-ion battery cathode material different discharge rate capacity test curve, 0.1C, 0.2C discharge capacity is 155mAhg -1 , 0.5C, 1C, 2C, 5C discharge capacity is 148mAhg -1 ,...

Embodiment 3

[0022] According to the molar ratio of iron, phosphorus, lithium and vanadium as 1:1.05:1.1:0.05, weigh ferric oxide, lithium dihydrogen phosphate, lithium vanadate and vanadium pentoxide and mix them until the mass fraction is 3% polyacrylamide was ball milled in an aqueous solvent, the milling speed was 1000r / min, and the milling time was 10h. Transfer the slurry to spray drying, the inlet temperature during spraying is 170°C, the outlet is 80°C, the pump speed is 15Hz, and the nozzle speed is 45Hz. And transfer the dried precursor to an inert atmosphere protection furnace, pass nitrogen protection, raise the temperature to 400°C at a rate of 2°C / min, keep it warm for 8 hours, then raise the temperature to 720°C at a rate of 8°C / min, keep it warm 12h, Li was obtained after cooling 3 V 2 (PO4 ) 3 Coated Nano LiFePO 4 Lithium-ion battery cathode material.

[0023] Li obtained by the above method 3 V 2 (PO 4 ) 3 Coated Nano LiFePO 4 Coated Nano LiFePO 4 Lithium-ion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com