Sensitization-free chemical nickel-plating method of conducting glass

A technology of conductive glass and electroless nickel plating, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of cumbersome steps, high precision requirements of process conditions, and high cost of raw materials, so as to simplify the pretreatment steps , metal terminals and connecting lines with clear texture and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

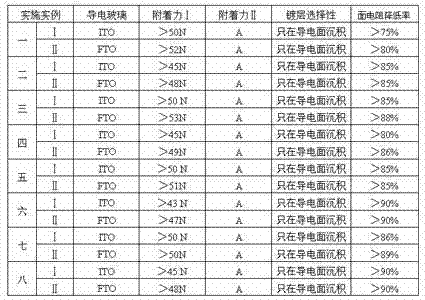

Examples

Embodiment 1

[0029] Implementation example 1: (1) degreasing at 25°C for 6 minutes, the formula of degreasing liquid is sodium carbonate 1.0%, sodium phosphate 1.0%, sodium hydroxide 0.5%, sodium lauryl sulfate 0.008%; (2) 25°C Roughen at high temperature for 5 minutes, the formula of roughening solution is potassium hydrogen persulfate 1.0%, potassium persulfate 2.0%, potassium sulfate 5.0%, ethanol 1.5%, sulfuric acid 0.01%, acetic acid 0.4%; (3) Degumming at 25°C for 6 minutes , the degumming solution formula is 0.01% hydrochloric acid, 0.01% sulfuric acid; (4) Catalyzed at 25°C for 8 minutes, the catalytic solution formula is cuprous chloride 1.0%, cupric chloride 2.5%, succinic acid 1.0%, dodecane Sodium sulfite 0.01%; (5) Activation at 25°C for 6 minutes, the formula of the activation solution is sodium hypophosphite 0.1%, acetic acid 1.5%; (6) Electroless nickel plating at 80°C for 3 minutes, the formula of the electroless plating solution is hexahydrate Nickel sulfate 2.0%, trisodi...

Embodiment 2

[0030]Implementation example 2: (1) degreasing at 35°C for 3 minutes, the formula of degreasing liquid is sodium carbonate 2.0%, sodium phosphate 2.0%, sodium hydroxide 0.1%, sodium lauryl sulfate 0.005%; (2) 35°C Roughen at high temperature for 3 minutes, the formula of roughening solution is 2.0% potassium persulfate, 2.0% potassium persulfate, 0.5% ethanol, 1.0% sulfuric acid, 0.2% formic acid; (3) Degumming at 35°C for 3 minutes, formula Nitric acid 0.05%, sulfuric acid 0.05%; (4) Catalyze at 35°C for 5 minutes, and the formula of the catalytic solution is 0.05% stannous chloride, 0.1% potassium chloride, 0.01% lactic acid, and 0.0001% sodium lauryl sulfate; ( 5) Activation at 35°C for 3 minutes, the formula of the activation solution is sodium hypophosphite 2.0%, 0.5% formic acid; (6) Electroless nickel plating at 65°C for 8 minutes, the formula of the electroless plating solution is nickel sulfate hexahydrate 2.5%, citric acid Trisodium 1.0%, succinic acid 1.0%, sodium h...

Embodiment 3

[0031] Implementation Example 3: (1) Oil removal at 30°C for 5 minutes, the oil removal liquid formula is 3.0% sodium carbonate, 0.1% sodium phosphate, 0.01% sodium hydroxide, 0.001% sodium lauryl sulfate; (2) 30°C Roughening at high temperature for 8 minutes, the formula of the roughening solution is potassium persulfate 3.5%, potassium sulfate 1.0%, ethanol 0.8%, sulfuric acid 0.05%, lactic acid 1.0%; (3) 30°C for 8 minutes, the formula of the degumming solution is Phosphoric acid 2.0%, sulfuric acid 1.0%; (4) Catalyze at 30°C for 3 minutes, the formula of the catalytic solution is silver nitrate 0.01%, sodium acetate 5.0%, acetic acid 0.05%, sodium lauryl sulfate 0.0005%; (5) 30°C Activation at low temperature for 8 minutes, the formula of the activation solution is sodium hypophosphite 1.0%, lactic acid 1.0%; (6) Electroless nickel plating at 70°C for 5 minutes, the formula of the electroless plating solution is 3.0% of nickel sulfate hexahydrate, 0.5% of lactic acid, butan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com