Carboxylesterase and application thereof in degradation of pesticides malathion and carbaryl

A technology of carboxylesterase and malathion, applied in the field of bioengineering, can solve the problems of limited enzyme production ability of wild strains, high production cost, long fermentation cycle, etc., achieve efficient degradation of malathion, easy to obtain pure Effect of improving protein and degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Carboxylesterase Gene D-1CarE3 clone

[0047] Extract the genomic DNA of thermophilic Alicyclobacillus D-1: CTAB lysis method, the specific steps are: centrifuge the fresh bacterial liquid cultured in liquid for 12 hours, and add 800 μL solution Ⅰ (20 mM Tris, pH8.0, 2 mM Na 2 -EDTA, final concentration 20 mg / mL lysozyme), incubated at 37°C for 30 min, added 100 μL 10% SDS and mixed up and down, then added 10 μL 10 mg / mL proteinase K, incubated at 37°C for 30 min, added 150 μL μL 5 M NaCl and 150 μL 10% CTAB solution were mixed upside down, incubated at 65°C for 20 min, divided into 600 μL tubes, and then added 600 μL phenol / chloroform / isopropanol (volume ratio 25:24:1) For extraction, centrifuge at 12000 rpm for 10 min at 4 °C, take 300 μL of the supernatant and extract again in 300 μL chloroform / isopropanol (volume ratio 24:1) to remove impurities, and centrifuge at 12000 rpm for 10 min at 4 °C , then take the supernatant and add 2 times the volume of a...

Embodiment 2

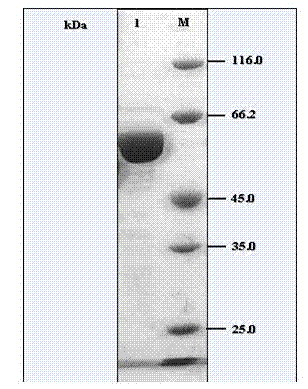

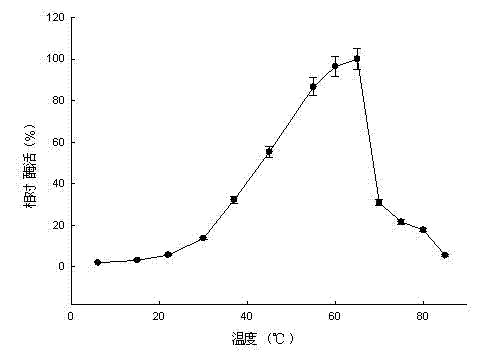

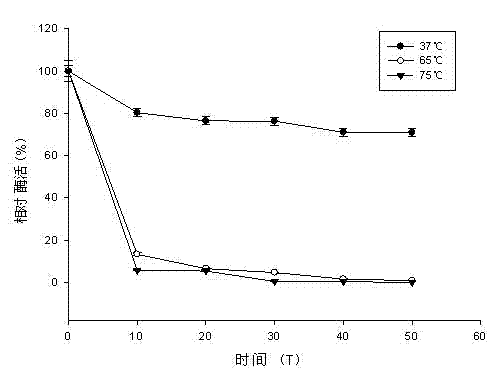

[0054] Embodiment 2: Preparation of recombinant carboxylesterase D-1CarE3

[0055] pET -D-1CarE3 of Escherichia coli BL21(DE3) strain and pET-only - Empty plasmid for 28a(+) Escherichia coli BL21(DE3) strain was inoculated in LB (50 μg / mL Kan) medium with 0.1% inoculum, and shaken rapidly at 37 °C for 16 h. Then inoculate the activated bacterial solution into fresh LB (50 μg / mL Kan) culture solution with 1% inoculum, and culture with rapid shaking for about 2–3 h (OD 600 After reaching 0.6–1.0), add IPTG at a final concentration of 0.7 mM for induction, and continue shaking culture at 20 °C for about 20 h or at 26 °C for about 8 h. Centrifuge at 12000 rpm for 5 min to collect the cells. After suspending the cells with an appropriate amount of pH7.0 Tris-HCl buffer solution, the cells were disrupted by ultrasonic waves in a low-temperature water bath. The above intracellular concentrated crude enzyme solution was centrifuged at 13,000 rpm for 10 min, the supernat...

Embodiment 3

[0070] Application of Purified Recombinant Carboxylesterase D-1CarE3 in Degradation of Pesticides Malathion and Carbaryl

[0071] 1. The degradation effect of recombinant carboxylesterase D-1CarE3 on the pesticide malathion:

[0072] Take 1 mL of purified recombinant carboxylesterase D-1CarE3 diluted 100 times and add it to 1 / 15 mol / L, pH7.0 disodium hydrogen phosphate-dihydrogen phosphate containing 5 mg / L pesticide malathion In the potassium buffer solution, the total reaction system was 3 mL, and the reaction was shaken at 37 °C; in the control group, the enzyme solution was not added, and the enzyme solution was replaced by 1 mL of disodium hydrogen phosphate-potassium dihydrogen phosphate buffer solution with pH 7.0, every 20 min Take out 0.5 mL of the reaction solution and mix it with an equal volume of n-hexane, shake it, centrifuge at 12000 rpm for 2 min, add 0.2 g of anhydrous sodium sulfate to the upper layer of the extract to remove water, centrifuge at 12000 rpm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com