BeMgZnO-based MSM solar blind detector and preparation method thereof

An ultraviolet detector, 3.37ev technology, applied in the field of ultraviolet detectors, can solve the problems of bulky volume, reduced quantum efficiency, limited energy band adjustment, etc., and achieves the effects of good light response, simple preparation process, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

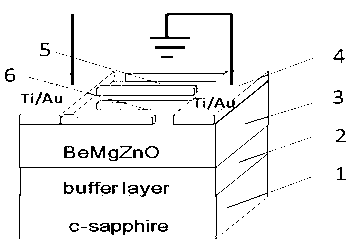

[0032] Such as figure 1 , 2 Shown in and 3, a kind of BeMgZnO-based MSM structure ultraviolet detector comprises a substrate 1, a buffer layer 2 is deposited on the substrate 1, a thin film layer 3 is grown on the buffer layer 2; a metal contact is made on the thin film layer 3 The pattern of the interdigitated electrodes 4, the gap between the interdigitated electrodes 4 is the photosensitive area 6.

[0033] The film layer 3 is a BeMgZnO quaternary alloy film layer, and the thickness of the BeMgZnO quaternary alloy film layer is 200nm~1um; the BeMgZnO quaternary alloy film layer adjusts the band gap by adjusting the atomic ratio of the three elements of beryllium, magnesium and zinc, The forbidden band width is 3.37eV~6.2eV.

[0034] In this embodiment, when the substrate is sapphire polished on both sides, the orientation of the sapphire polished on both sides is c-orientation. The interdigitated electrodes are made of titanium (Ti) and gold (Au).

[0035] The preparati...

Embodiment 2

[0041] This embodiment is the same as Embodiment 1 except for the following features: In this embodiment, in step 4), the interdigitated electrodes are selected from titanium (Ti), aluminum (Al), nickel (Ni), gold (Au) , platinum (Pt), silver (Ag), iridium (Ir), molybdenum (Mo), tantalum (Ta), niobium (Nb), cobalt (Co), zirconium (Zr) and tungsten (W) and other metals. The required metal can be selected according to the needs. For example, platinum (Pt) has a higher work function, and the electrode can form a Schottky contact; while titanium (Ti), aluminum (Al), and gold (Au) can form an ohmic contact.

[0042]

Embodiment 3

[0044] This embodiment is the same as Embodiment 1 except for the following features: In this embodiment, in step 3), a thin film layer is grown on the buffer layer by chemical vapor deposition (MOCVD).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com