Preparation method for zinc telluride homoepitaxy layer

A homoepitaxial, zinc telluride technology, applied in chemical instruments and methods, from chemically reactive gases, semiconductor/solid-state device manufacturing, etc., can solve the problem of affecting the luminescence performance of ZnTe epitaxial layer, harmful parasitic reactions and gas phase nucleation, Affect the quality of the epitaxial layer and other issues, to achieve the effect of inhibiting gas phase nucleation, inhibiting parasitic reactions, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

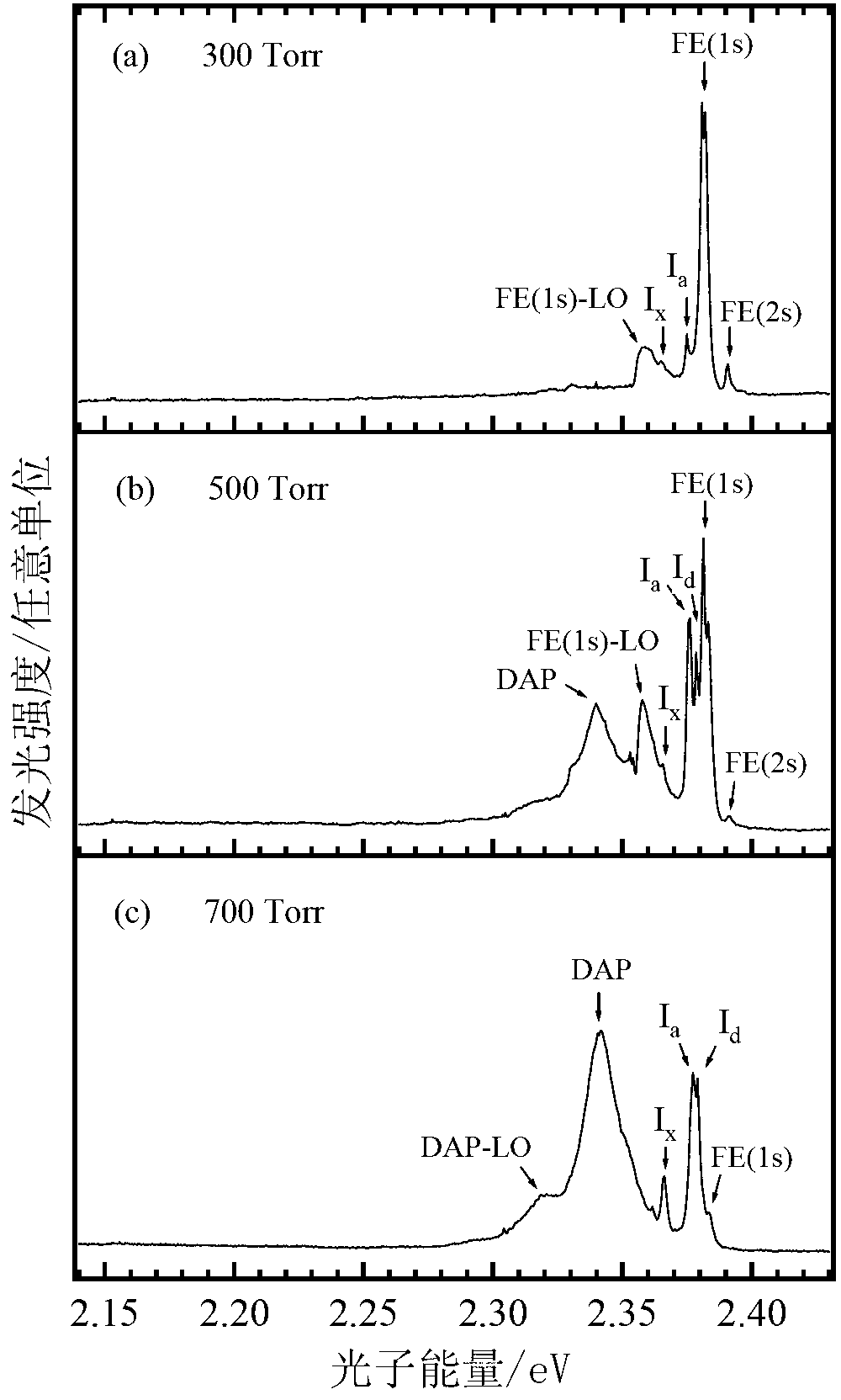

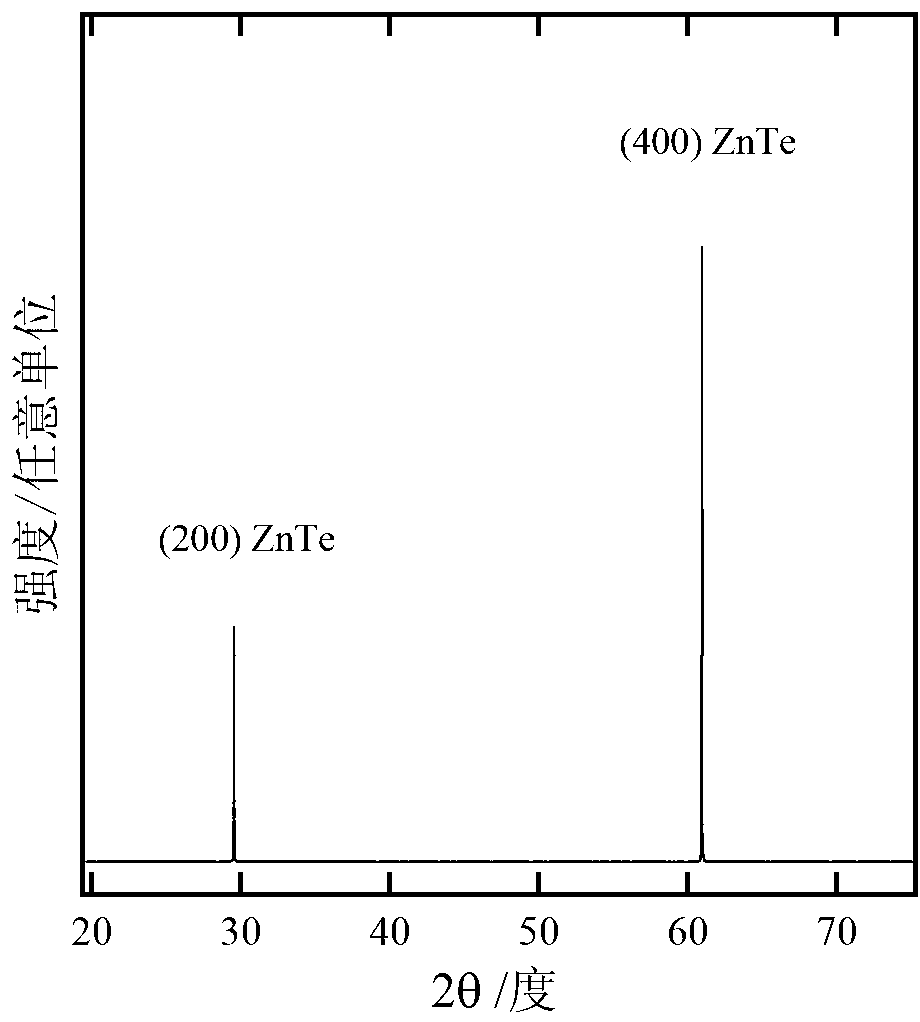

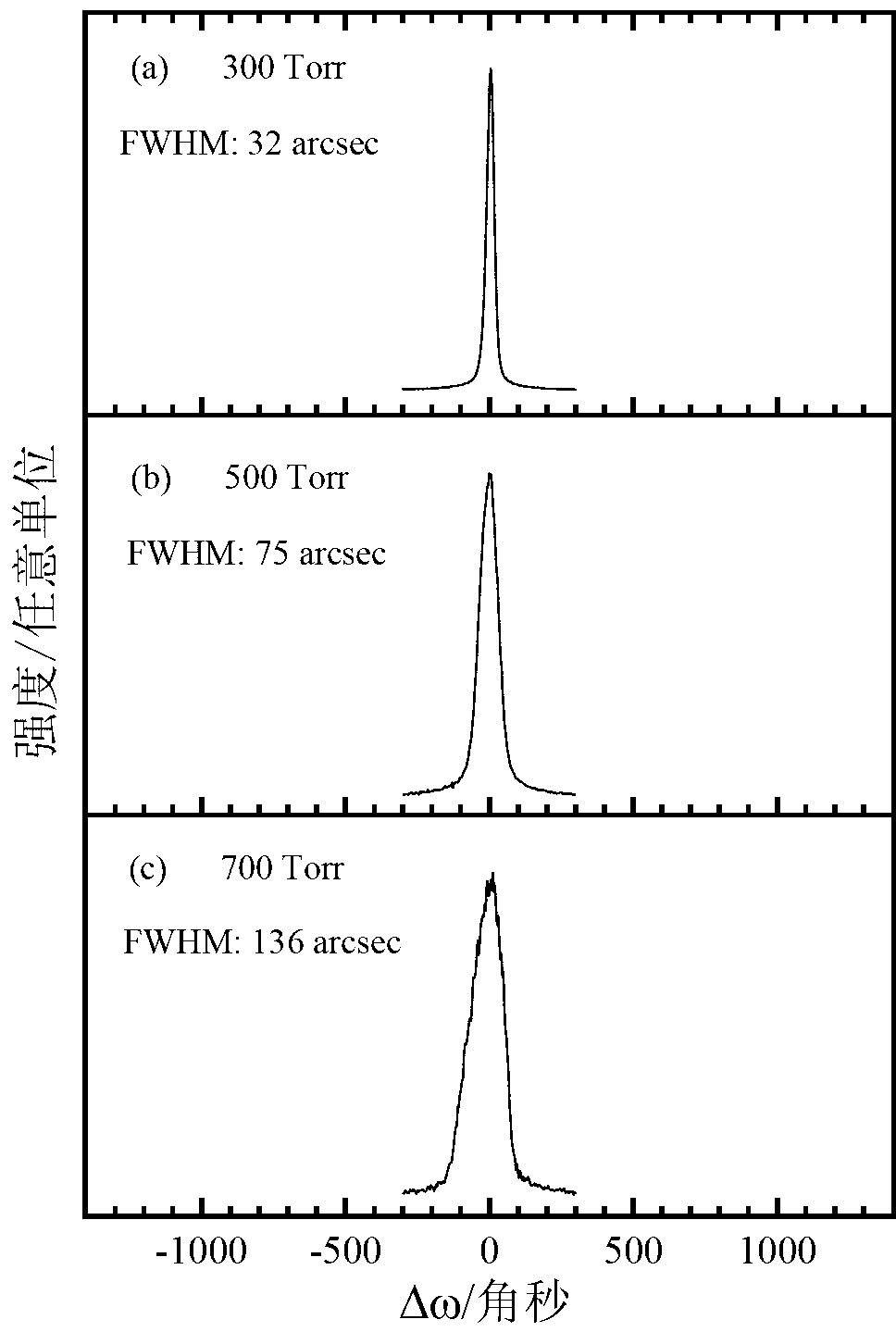

Embodiment 1

[0044] A method for preparing a homogeneous epitaxial layer of zinc telluride, adopts a metal organic chemical vapor phase epitaxy process, uses dimethyl zinc and diethyl tellurium as metal organic sources, uses hydrogen as a carrier gas, and uses low pressure metal organic chemical vapor phase epitaxy equipment Growing zinc telluride epitaxial layer on ZnTe (100) substrate; the process conditions are as follows:

[0045] Substrate temperature during growth: 400°C;

[0046] Reaction chamber pressure: 300 Torr;

[0047] Transport rate of dimethyl zinc: 15μmol / min;

[0048] Diethyl tellurium transport rate: 15μmol / min;

[0049] Growth time: 3 hours

[0050] The operation steps of the above preparation method are as follows:

[0051] 1. Cleaning of ZnTe substrate: The (100) surface ZnTe substrate is ultrasonically cleaned in organic solvent acetone for 5 minutes, then placed in a 1% bromine methanol solution for 30 minutes, and finally rinsed with deionized water;

[0052] 2. Pass the reacti...

Embodiment 2

[0057] The process conditions are as follows:

[0058] Reaction chamber pressure: 700Torr;

[0059] Substrate temperature during growth: 380°C;

[0060] Transport rate of dimethyl zinc: 10μmol / min;

[0061] Diethyl tellurium transport rate: 10μmol / min;

[0062] Growth time: 4 hours.

[0063] The low-pressure MOVPE process prepares the zinc telluride epitaxial layer, the steps are as follows:

[0064] 1. Cleaning of ZnTe substrate: The (100) surface ZnTe substrate was ultrasonically cleaned in organic solvent acetone for 5 minutes, then placed in a 1% bromine methanol solution for 20 minutes, and finally rinsed with deionized water;

[0065] 2. Pass the reaction chamber of the MOVPE equipment into H 2 , Keep at 550°C for 30 minutes to remove the oxide on the surface of the ZnTe substrate;

[0066] 3. Control the substrate temperature at 380°C and adjust the hydrogen flow rate to maintain the transport rates of both dimethyl zinc (DMZn) and diethyl tellurium (DETe) at 10 μmol / min, and control...

Embodiment 3

[0069] The process conditions are as follows:

[0070] Substrate temperature during growth: 420°C;

[0071] Reaction chamber pressure: 500 Torr;

[0072] Transport rate of dimethyl zinc: 30μmol / min;

[0073] Diethyl tellurium transport rate: 30μmol / min;

[0074] Growth time: 2 hours;

[0075] The MOVPE process prepares the zinc telluride epitaxial layer, the steps are as follows:

[0076] 1. Cleaning of ZnTe substrate: The (100) surface ZnTe substrate was ultrasonically cleaned in organic solvent acetone for 5 minutes, then placed in a 1% bromine methanol solution for 20 minutes, and finally rinsed with deionized water;

[0077] 2. Pass the reaction chamber of the MOVPE equipment into H 2 , Keep at 420°C for 30 minutes to remove the oxide on the surface of the ZnTe substrate;

[0078] 3. Control the substrate temperature at 420°C, adjust the hydrogen flow rate, maintain the transport rates of both dimethyl zinc (DMZn) and diethyl tellurium (DETe) at 30 μmol / min, and control the reaction cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com