Tungsten and boron-containing two-phase catalyst, and preparation method and application thereof in epoxidation

A catalyst, epoxy cyclohexane technology, applied in the preparation of oxidation reaction, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the complex reaction product, complex preparation, poor selectivity and other problems, to achieve the effect of simple separation and recovery, simple preparation process and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

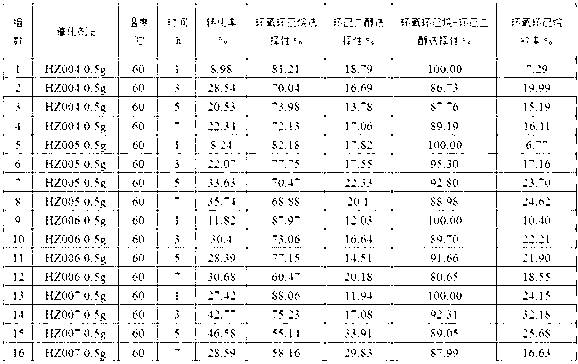

Examples

Embodiment 1

[0027] Take 100mL of 0.5mol / L sodium tungstate aqueous solution, slowly add 16.35g of 30% dilute sulfuric acid; add 2.04g of 30% hydrogen peroxide dropwise, react for tens of minutes; add 1.96g boric acid to 60 Stir at ℃ for 30min; add 6.68g cetyltrimethylammonium chloride and stir at 60℃ for 60min; after the reaction, the solid phase is obtained by filtration, washed with deionized water, and dried in air at 40℃ for 11h to obtain Tungsten and boron two-phase catalyst HZ004.

Embodiment 2

[0029] Take 50mL of 1mol / L sodium tungstate aqueous solution, slowly add 20.44g of 30% dilute sulfuric acid; add 2.54g of 30% hydrogen peroxide dropwise, react for tens of minutes; add 1.96g of boric acid at 60℃ Stir for 30 min at the same time; add 6.68 g of certain quaternary ammonium salt and stir at 60°C for 60 min; after the reaction, the solid phase is obtained by filtration, washed with deionized water, and dried in air at 40°C for 11 h to obtain a two-phase catalyst containing tungsten and boron HZ005.

Embodiment 3

[0031] Take 100mL of 0.5mol / L sodium tungstate aqueous solution, slowly add 24.53g of 30% dilute sulfuric acid; add 2.61g of 30% hydrogen peroxide dropwise, and react for tens of minutes; add 12.09g of sodium borate to Stir at 60°C for 30min; add 7.67g cetyltrimethylammonium bromide and stir at 60°C for 60min; after the reaction, the solid phase is obtained by filtration, washed with deionized water, and dried in the air at 40°C for 11h to obtain Contains two-phase catalyst HZ006 of tungsten and boron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com