Preparation technology of hydroxyapatite-containing composite biological film on titanium-base surface

A hydroxyapatite, preparation technology, applied in surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of poor wear resistance, thick coating, lack of biological activity, etc., to shorten the reaction time, Lower reaction temperature, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

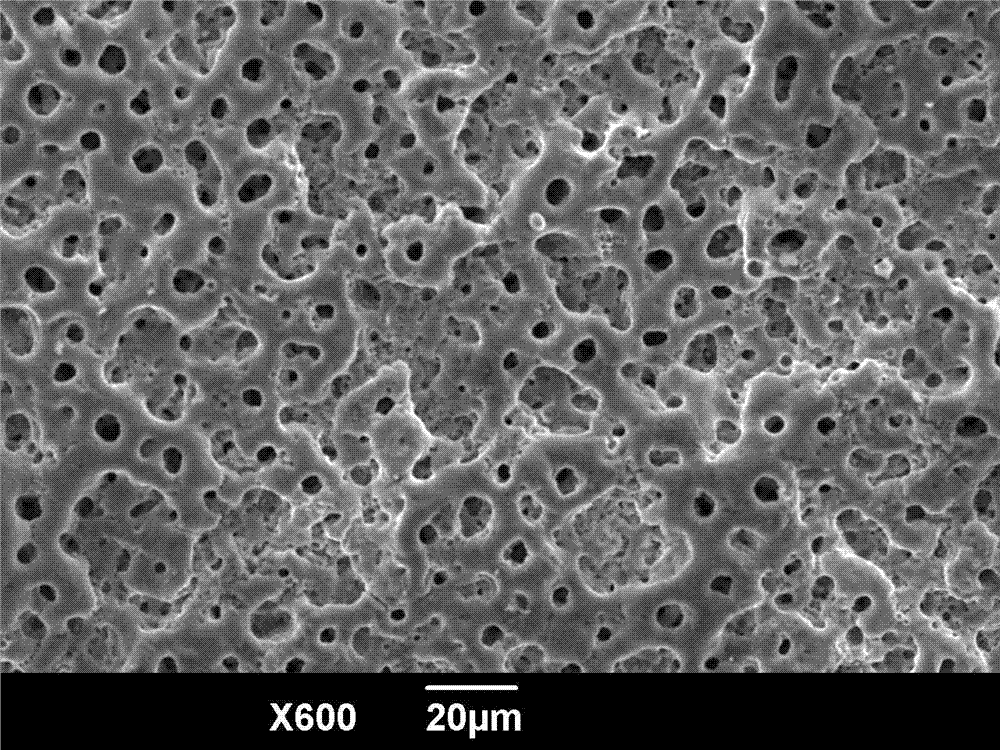

Embodiment 1

[0027] Dissolve 0.25mol / L calcium acetate and 0.06mol / L β-calcium glycerophosphate in deionized water, stir and mix well, let stand for half an hour, and completely immerse the polished titanium or titanium alloy in the microarc In the oxidation electrolyte, titanium or titanium alloy is used as the anode, and stainless steel is used as the cathode for micro-arc oxidation. During the whole process, the temperature of the electrolyte is controlled at about 25°C. The power supply for micro-arc oxidation is a pulse power supply. The process parameters are: voltage 300-450, the duty ratio is 20%, the frequency is 600Hz, the oxidation time is 15min, a layer of dense and uniform ceramic oxide film is formed on the surface of the sample, and the obtained ceramic oxide film is washed with tap water to remove the ceramic oxide film For the residual electrolyte on the surface, dry the sample after washing with tap water for later use.

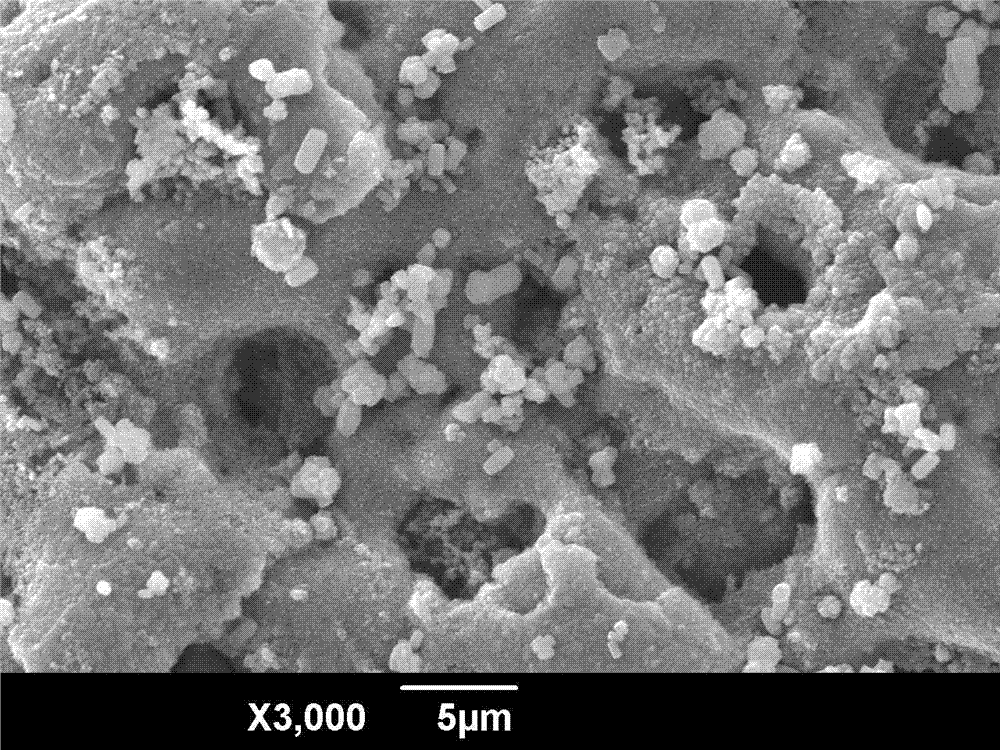

Embodiment 2

[0030]Dissolve 0.25mol / L calcium acetate and 0.06mol / L β-calcium glycerophosphate in deionized water, stir and mix well, let stand for half an hour, and completely immerse the polished titanium or titanium alloy in the microarc In the oxidation electrolyte, titanium or titanium alloy is used as the anode, and stainless steel is used as the cathode for micro-arc oxidation. During the whole process, the temperature of the electrolyte is controlled at about 25°C. The power supply for micro-arc oxidation is a pulse power supply. The process parameters are: voltage 300-450, the duty ratio is 20%, the frequency is 600Hz, the oxidation time is 15min, a layer of dense and uniform ceramic oxide film is formed on the surface of the sample, and the obtained ceramic oxide film is washed with tap water to remove the ceramic oxide film For the residual electrolyte on the surface, dry the sample after washing with tap water for later use.

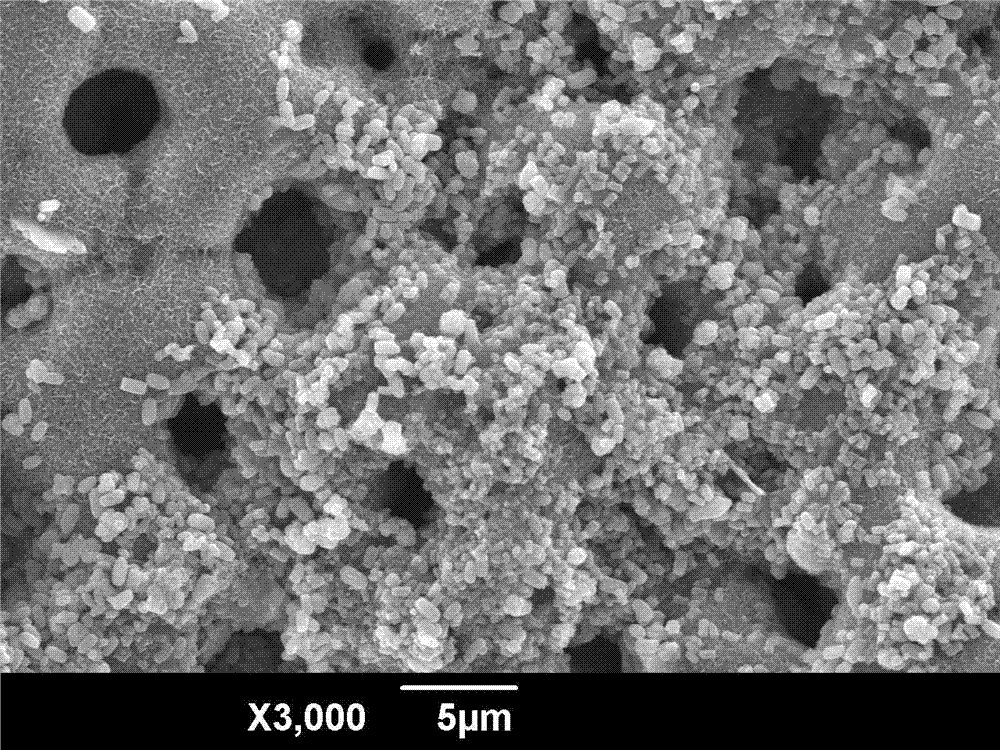

Embodiment 3

[0033] Dissolve 0.25mol / L calcium acetate and 0.06mol / L β-calcium glycerophosphate in deionized water, stir and mix well, let stand for half an hour, and completely immerse the polished titanium or titanium alloy in the microarc In the oxidation electrolyte, titanium or titanium alloy is used as the anode, and stainless steel is used as the cathode for micro-arc oxidation. During the whole process, the temperature of the electrolyte is controlled at about 25°C. The power supply for micro-arc oxidation is a pulse power supply. The process parameters are: voltage 300-450, the duty ratio is 20%, the frequency is 600Hz, the oxidation time is 15min, a layer of dense and uniform ceramic oxide film is formed on the surface of the sample, and the obtained ceramic oxide film is washed with tap water to remove the ceramic oxide film For the residual electrolyte on the surface, dry the sample after washing with tap water for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com