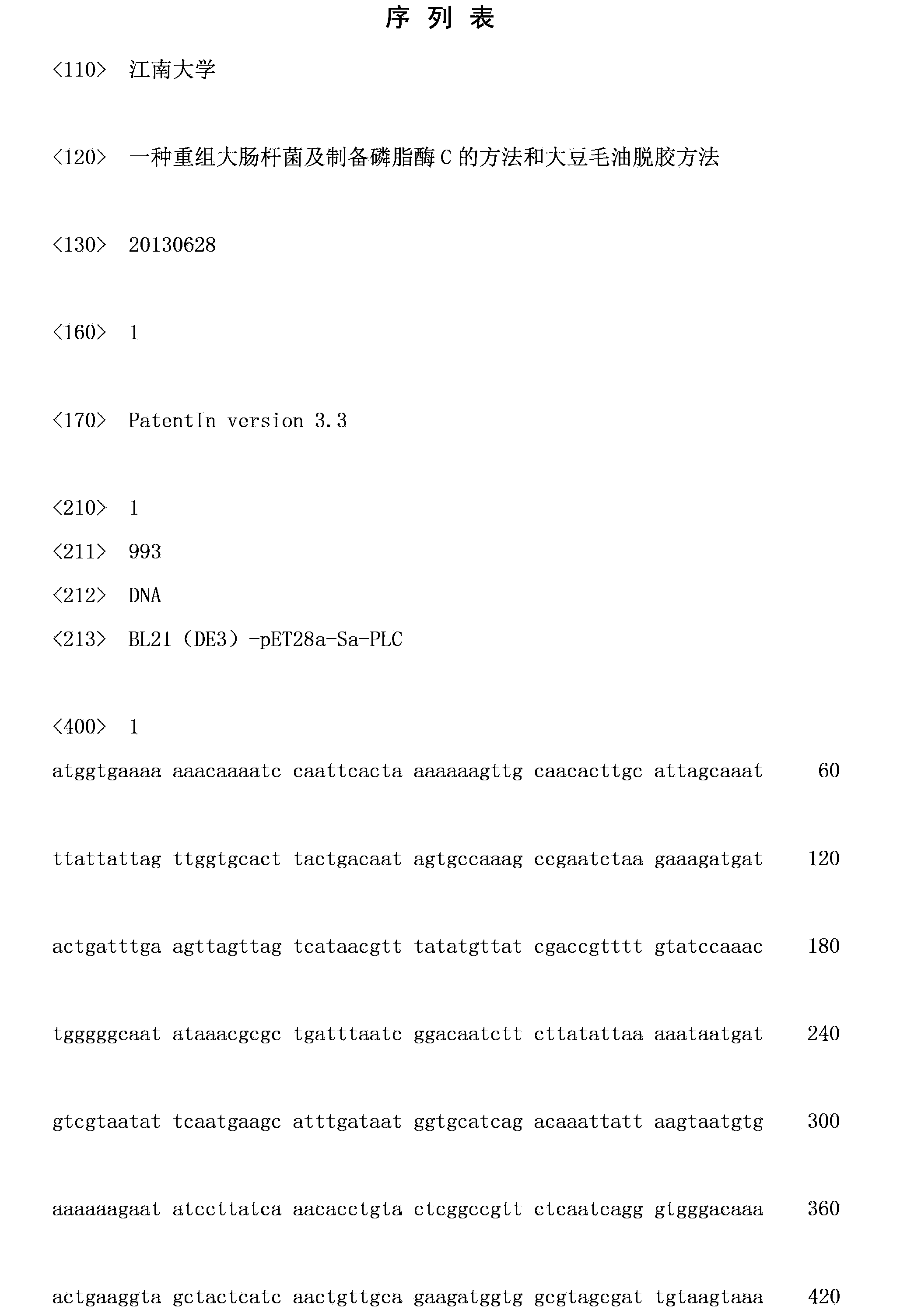

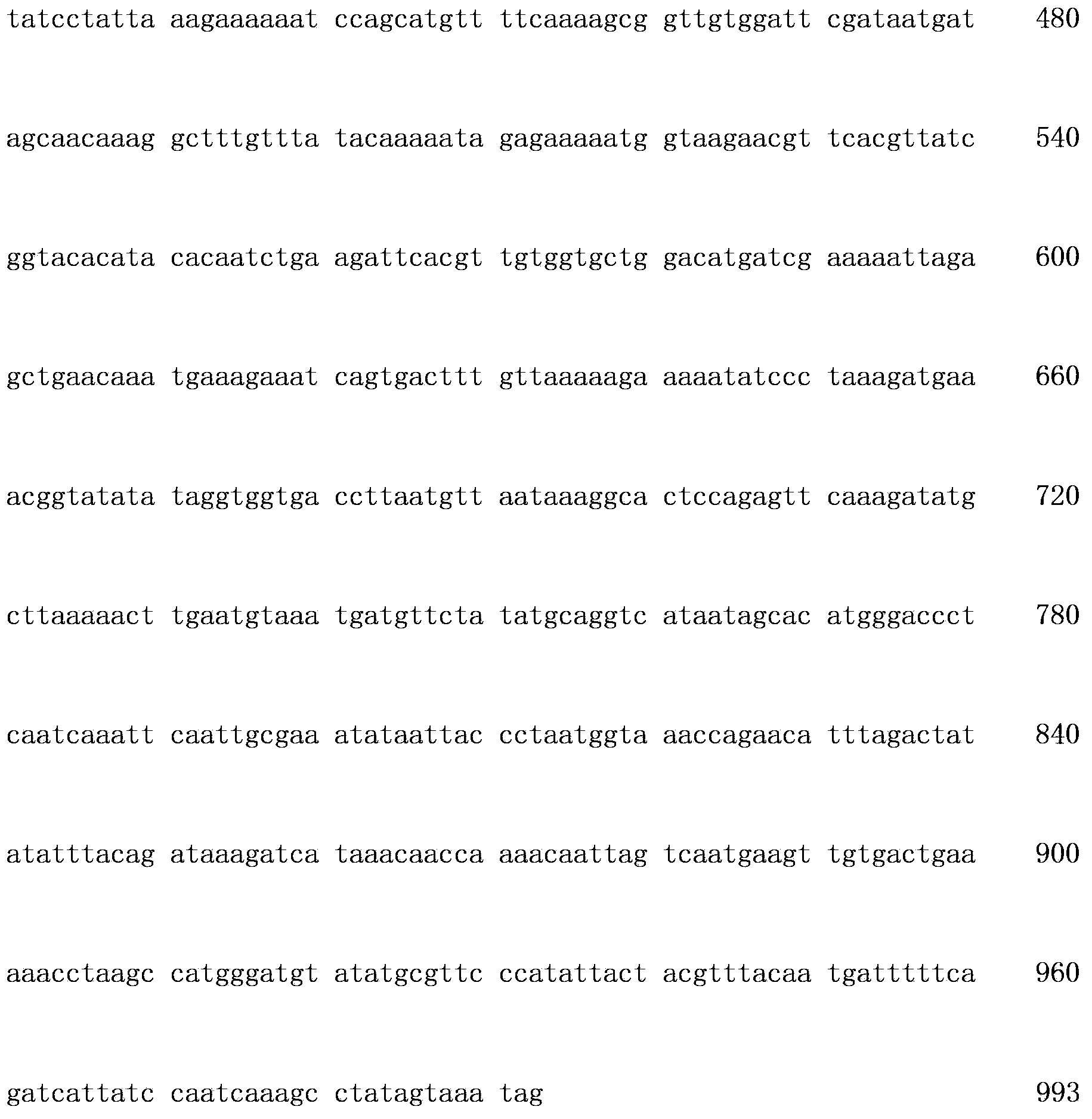

Recombinant escherichia coli, method for preparing phospholipase C and method for degumming soybean crude oil

A technology of recombinant Escherichia coli and phospholipase, which is applied in the fields of biotechnology and oil degumming, can solve problems such as unsatisfactory acid and heat tolerance, limited application, and safety, and achieve low cost, convenient enzyme source, and reduced loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The composition of the seed medium is: NaCl 10g / L, peptone 10g / L, yeast extract 5g / L, pH 7.4, sterilized at 121°C for 20min.

[0034] The components of the fermentation medium are: peptone 12g / L, yeast extract 24g / L, glycerol 0.4% (v / v), KH 2 PO 4 170mM, K 2 HPO 4 720mM, 121°C, sterilized for 20min.

[0035] Inoculate the recombinant Escherichia coli BL21(DE3)-pET28a-Sa-PLC in the seed medium containing kanamycin sulfate 50mg / mL, and culture it in a shake flask at 37°C and 200r / min until the logarithmic growth phase, as the seed solution Then inoculate the seed liquid into 20mL fermentation medium containing kanamycin sulfate 50mg / mL by 5% inoculum size, and culture it in 200r / min shake flask at 37°C until OD 600 =0.6, then add IPTG to a final concentration of 0.05mM, induce culture at 30°C, 200r / min for 8h; centrifuge the fermentation broth at 4°C, 8000r / min for 10min, collect the bacteria, and use 50mM Tris- Resuspend the bacteria in HCl, sonicate for 10 minutes,...

Embodiment 2

[0037] The composition of the seed medium is: NaCl 10g / L, peptone 10g / L, yeast extract 5g / L, pH 7.4, sterilized at 121°C for 20min.

[0038] The components of the fermentation medium are: peptone 12g / L, yeast extract 24g / L, glycerol 0.4% (v / v), KH 2 PO 4 170mM, K 2 HPO 4 720mM, 121°C, sterilized for 20min.

[0039] Inoculate the recombinant Escherichia coli BL21(DE3)-pET28a-Sa-PLC in the seed medium containing kanamycin sulfate 50mg / mL, and culture it in the shake flask at 37°C and 180r / min until the logarithmic growth phase, as the seed solution ;Then inoculate the seed liquid into 20mL fermentation medium containing kanamycin sulfate 50mg / mL by 1% inoculum size, and culture it in shake flask at 37°C and 180r / min until OD 600 =1.0, then add IPTG to a final concentration of 0.005mM, induce culture at 37°C, 180r / min for 5h; centrifuge the fermentation broth at 4°C, 8000r / min for 10min, collect the bacteria, and use 50mM Tris- The cells were resuspended in HCl, sonicated fo...

Embodiment 3

[0041] The composition of the seed medium is: NaCl 10g / L, peptone 10g / L, yeast extract 5g / L, pH 7.4, sterilized at 121°C for 20min.

[0042] The components of the fermentation medium were: peptone 12g / L, yeast extract 24g / L, glycerin 0.4% (v / v), sterilized at 121°C for 20min.

[0043] Inoculate the recombinant Escherichia coli BL21(DE3)-pET28a-Sa-PLC in the seed medium containing kanamycin sulfate 50mg / mL, and culture it in a shake flask at 37°C and 200r / min until the logarithmic growth phase, as the seed solution ;Then inoculate the seed liquid into 20mL fermentation medium containing kanamycin sulfate 50mg / mL according to the inoculation amount of 3%, directly add IPTG to the final concentration of 0.001mM, and induce culture at 30°C and 180r / min for 8h ;Centrifuge the fermentation broth at 4°C, 8000r / min for 10min, collect the cells, resuspend the cells with Tris-HCl of pH 7.2, ultrasonically break for 15min, and centrifuge the cell debris at 4°C, 10000r / min for 10min, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com