Particle dispersion toughening aluminum nitride ceramic substrate and preparation method thereof

A technology of aluminum nitride ceramics and particles, which is applied in the field of nitride ceramics, can solve the problems of undisclosed W, Mo particles, poor density of AlN ceramics, and unsatisfactory comprehensive performance, and achieve comprehensive performance improvement, high density, and economical processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

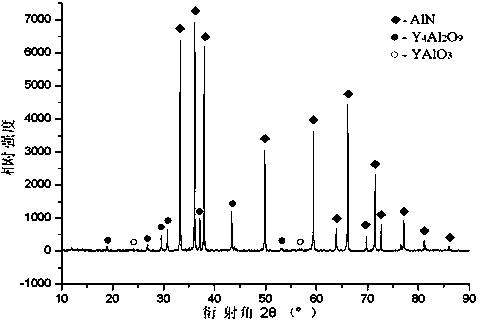

Embodiment 1

[0043] Add 4wt% of Y 2 o 3 Sintering aid, 3wt.% Mo as toughening phase, 93wt.% AlN powder. Use absolute ethanol as the medium to ultrasonically disperse for 20 minutes, roll the mixed slurry for 24 hours, and the ball milling speed is 150 rpm; dry the mixed slurry after ball milling with a rotary evaporator, sieve and put it into a graphite mold for pre-treatment. Compression molding, the pressure is 5MPa; use graphite paper to separate the powder from the inner wall of the graphite mold, and evenly spray BN mold release agent on the graphite paper, hot press sintering under the protection of nitrogen atmosphere, sintering temperature 1800 ℃, holding time 3h, pressure is 25MPa.

[0044] The properties of the prepared AlN ceramic samples are as follows:

[0045] density 3.362 g / cm 3 Relative density 99.5% Thermal conductivity 181w / m.k Fracture toughness 3.15±0.032MPa.m 1 / 2 Three point flexural strength 464MPa volume resistivity ...

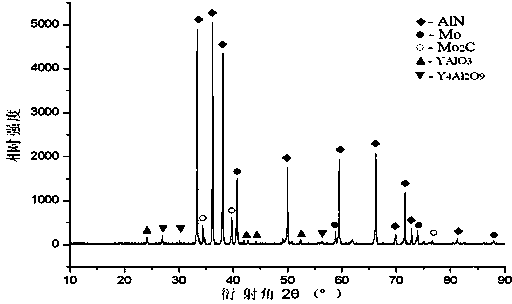

Embodiment 2

[0047] Add 4wt% of Y 2 o 3 Sintering aid, 5wt.% Mo as toughening phase, 91wt.% AlN powder. Use absolute ethanol as the medium to ultrasonically disperse for 20 minutes, roll the mixed slurry for 24 hours, and the ball milling speed is 150 rpm; dry the mixed slurry after ball milling with a rotary evaporator, sieve and put it into a graphite mold for pre-treatment. Compression molding, the pressure is 5MPa; use graphite paper to separate the powder from the inner wall of the graphite mold, and evenly spray BN mold release agent on the graphite paper, hot press sintering under the protection of nitrogen atmosphere, sintering temperature 1800 ℃, holding time 3h, pressure It is 25MPa, and its X-ray diffraction pattern is as follows image 3 , SEM picture as Figure 4 .

[0048] The properties of the prepared AlN ceramic samples are as follows:

[0049] density 3.369g / cm 3 Relative density 98.5% Thermal conductivity 180w / m.k Fracture toughness 3...

Embodiment 3

[0051] Add 4wt% of Y 2 o 3 Sintering aid, 3wt.% of W is the toughening phase, 93wt.% of AlN powder. Use absolute ethanol as the medium to ultrasonically disperse for 20 minutes, roll the mixed slurry for 24 hours, and the ball milling speed is 150 rpm; dry the mixed slurry after ball milling with a rotary evaporator, sieve and put it into a graphite mold for pre-treatment. Compression molding, the pressure is 5MPa; use graphite paper to separate the powder from the inner wall of the graphite mold, and evenly spray BN mold release agent on the graphite paper, hot press sintering under the protection of nitrogen atmosphere, sintering temperature 1800 ℃, holding time 3h, pressure is 25MPa.

[0052] The properties of the prepared AlN ceramic samples are as follows:

[0053] density 3.487 g / cm 3 Relative density 100% Thermal conductivity 171 w / m.k Fracture toughness 2.98±0.033MPa.m 1 / 2 Three point flexural strength 372MPa volume resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Three point flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com