Zinc icon mixed super capacitor

A technology of supercapacitors and zinc ions, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of low energy density, achieve the effect of simple preparation process and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

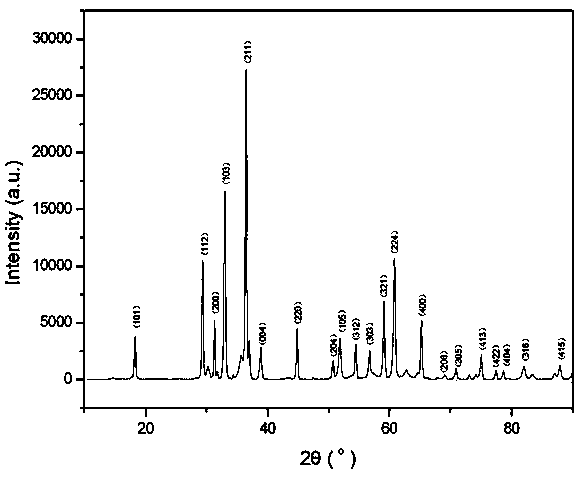

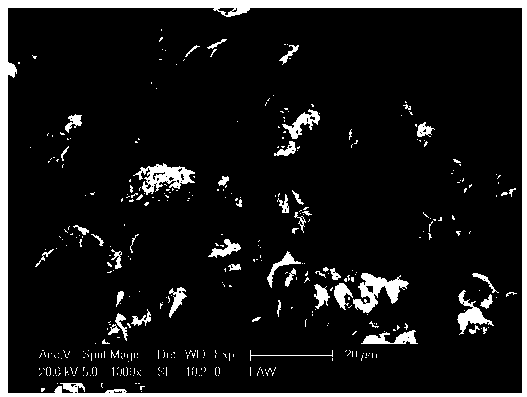

[0023] Weigh manganese carbonate, citric acid and zinc carbonate (the ratio of substances is 1:6:6). Manganese carbonate and citric acid were mixed evenly in water by magnetic stirring, heated to 60°C, reacted at constant temperature for 30 minutes, added zinc carbonate, continued to stir for 2 hours, cooled to room temperature, filtered the resulting product, washed with deionized water, and vacuumed at 60°C Dry to constant weight; calcinate the obtained product at 700°C for 2 hours to obtain zinc-manganese-oxygen composite metal oxide ZnMn 2 o 4 .

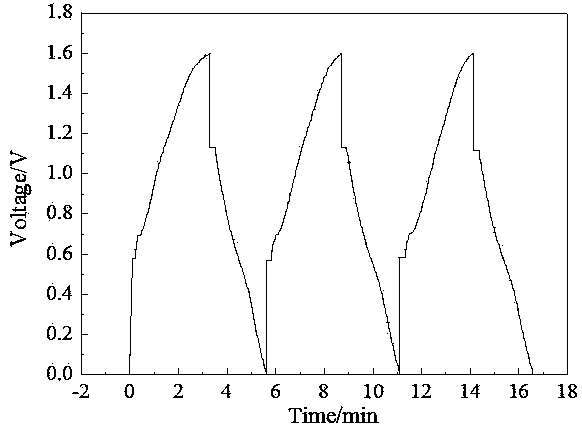

[0024] Weigh ZnMn according to the mass ratio of 70:20:10 2 o 4, VGCF, PTFE made of electrode film, pressed on a stainless steel mesh disc with a diameter of 16mm, and used as a positive electrode after drying; according to the mass ratio of 80:10:10, weigh the negative electrode active material (activated carbon), VGCF, PTFE to make electrode film , pressed on a stainless steel mesh disc with a diameter of 16mm, and used as ...

Embodiment 2

[0027] Weigh ferric oxide and zinc oxide according to the amount of substances at 1:1 and put them into a ball mill tank with a material to ball mass ratio of 1:20, and ball mill for 3 hours to obtain the precursor. The precursor was calcined at 700°C for 2 hours to obtain the zinc-iron composite metal oxide ZnFe 2 o 4 .

[0028] Weigh ZnFe according to the mass ratio of 70:20:10 2 o 4 , VGCF, PTFE made of slurry, coated on the titanium-free coating side of the activated carbon fiber cloth, cut into a disc with a diameter of 16mm, dried, and rolled as the positive electrode piece; according to the mass ratio of 73:17:10, the negative electrode was weighed Active material (the mass of activated carbon and mesophase carbon microspheres is 60:40), VGCF, and PTFE are used to make slurry, coated on the titanium-free coating side of activated carbon fiber cloth, cut into discs with a diameter of 16mm, dried, and rolled The pressure is used as the negative electrode sheet, and th...

Embodiment 3

[0031] According to the mass ratio of 1:2, zinc nitrate and cobalt nitrate were weighed to make an aqueous solution, and after stirring for 1 hour in a nitrogen atmosphere, sodium hydroxide was added to control the reaction time for 3 minutes. The product was washed and dried, and the obtained composite material precursor was calcined at 600°C for 1 hour to obtain the zinc-cobalt composite metal oxide ZnCo 2 o 4 .

[0032] Weigh ZnCo according to the mass ratio of 70:20:10 2 o 4 , VGCF, PTFE made of electrode film, pressed on a stainless steel mesh disc with a diameter of 16mm, and used as a positive electrode after drying; the negative active material was weighed according to the mass ratio of 79:11:10 (the mass ratio of graphene to expanded graphite is 70 : 30), VGCF, PTFE made of electrode film, pressed on a stainless steel mesh disc with a diameter of 16mm, dried as a negative electrode, the mass ratio of positive and negative electrodes is 1:1.6.

[0033] Stack the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com