High-capacity lithium ion battery gradient cathode material and preparation method thereof

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation process, difficulty in promotion, and poor battery cycle performance, so as to improve structural stability and improve Safety and electrochemical performance, effect of good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

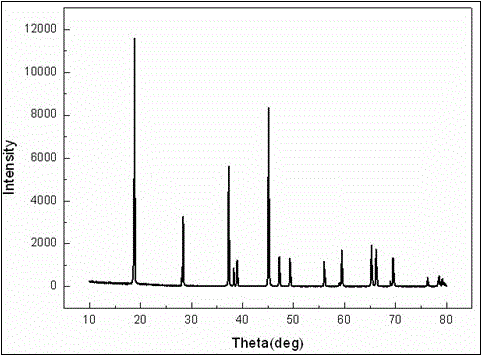

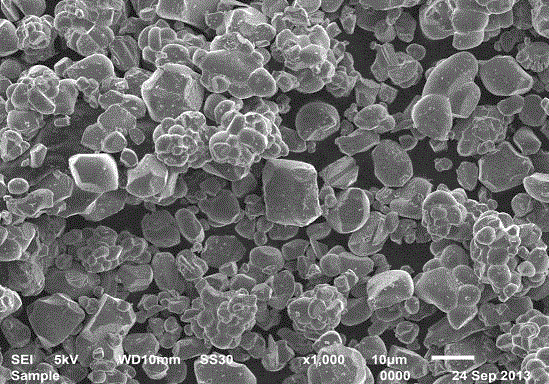

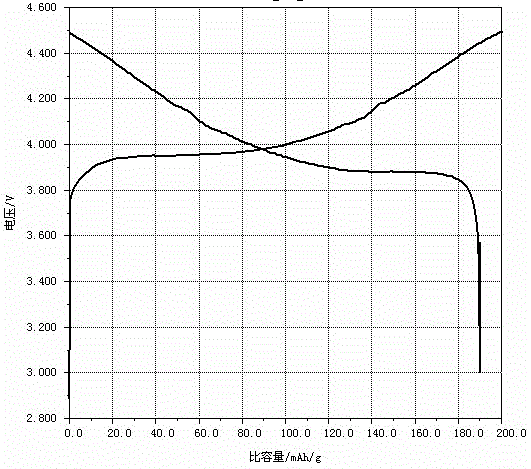

[0029] Embodiment 1: as figure 1 . A high-capacity lithium-ion battery graded cathode material shown in 2.3 and 4 contains a cobalt source material, a lithium source material, a dopant M and a coating material, wherein the molar ratio of Li: Co is 1.08, and the dopant M The dosage of the coating material is 0.1wt%, and the dosage of the cladding material is 10wt%.

[0030] Its preparation method comprises the following steps:

[0031] (1) Using battery-grade cobalt oxyhydroxide (D50 is 13 μm), battery-grade lithium hydroxide, magnesium oxide, and aluminum oxide as raw materials, the molar ratio of Li:Co is 1.08, the addition of aluminum is 0.1 wt%, and the addition of magnesium The amount is 1.5 wt%, placed in a dry mixer and mixed evenly.

[0032](2) In a wet environment, combine a mixed solution of Ni, Co, and Mn salts with a concentration of 0.5-3mol / L, a NaOH solution with a concentration of 1-10mol / L, and a complexing agent solution of 0.5-200g / L Put it into the reacti...

Embodiment 2

[0037] (1) Using battery-grade cobalt oxide (D50 is 20 μm), battery-grade lithium hydroxide, magnesium oxide, and zirconia as raw materials, the molar ratio of Li:Co is 0.95, the addition of zirconium is 4.5 wt%, and the addition of magnesium 5.5 wt%, placed in a dry mixer and mixed evenly.

[0038] (2) Put the materials in step (1) and the coating material N with a dosage of 0.01 wt% into the dry coating equipment for coating. The coating material N is a mixture of nickel oxide, tricobalt tetroxide, manganese tetraoxide, and lithium hydroxide and lithium carbonate, wherein the molar ratio of Ni:Co:Mn is 7:1.5:1.5, and the molar ratio of Li to metal nickel, cobalt, and manganese The ratio is 0.95.

[0039] (3) Sinter the materials processed in step (2). The main temperature of sintering is 550°C, and the sintering time in the main temperature zone is 40h. 3 / h, the sintered material is crushed, pulverized, and classified to obtain a semi-finished product of lithium cobaltate...

Embodiment 3

[0044] (1) Use battery-grade cobalt oxide (D50 is 20 μm), battery-grade lithium hydroxide, and titanium oxide as raw materials, the molar ratio of Li:Co is 1.2, and the addition of titanium is 0.01 wt%, and placed in a dry mixer well mixed.

[0045] (2) In a wet environment, a mixed solution of Ni, Co, and Mn salts with a concentration of 0.5-3 mol / L, a NaOH solution with a concentration of 1-10 mol / L, and a complexing agent solution of 0.5-200 g / L Add them together into the reaction vessel, control the appropriate temperature, pH value and stirring conditions, and then go through drying, iron removal, classification, sieving and other processes to obtain the substance N with a D50 of 1.5 μm (the molecular composition is Ni 0.8 mn 0.1 co 0.1 (OH) 2 ).

[0046] (3) Put the mixture in step (1) and the coating material N of 0.01 wt% into the dry coating equipment for coating. Among them, the coating material is a mixture of substance N (N is the substance synthesized in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com