Ethylene/alpha-alkene copolymerization catalyst as well as preparation and application thereof

An olefin copolymerization and catalyst technology, applied in the field of Ziegler-Natta catalysts, can solve the problems of ethylene/1-hexene copolymerization, difficult catalyst solid separation, uneven distribution of 1-hexene, etc., and achieve low cost and good particle shape , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

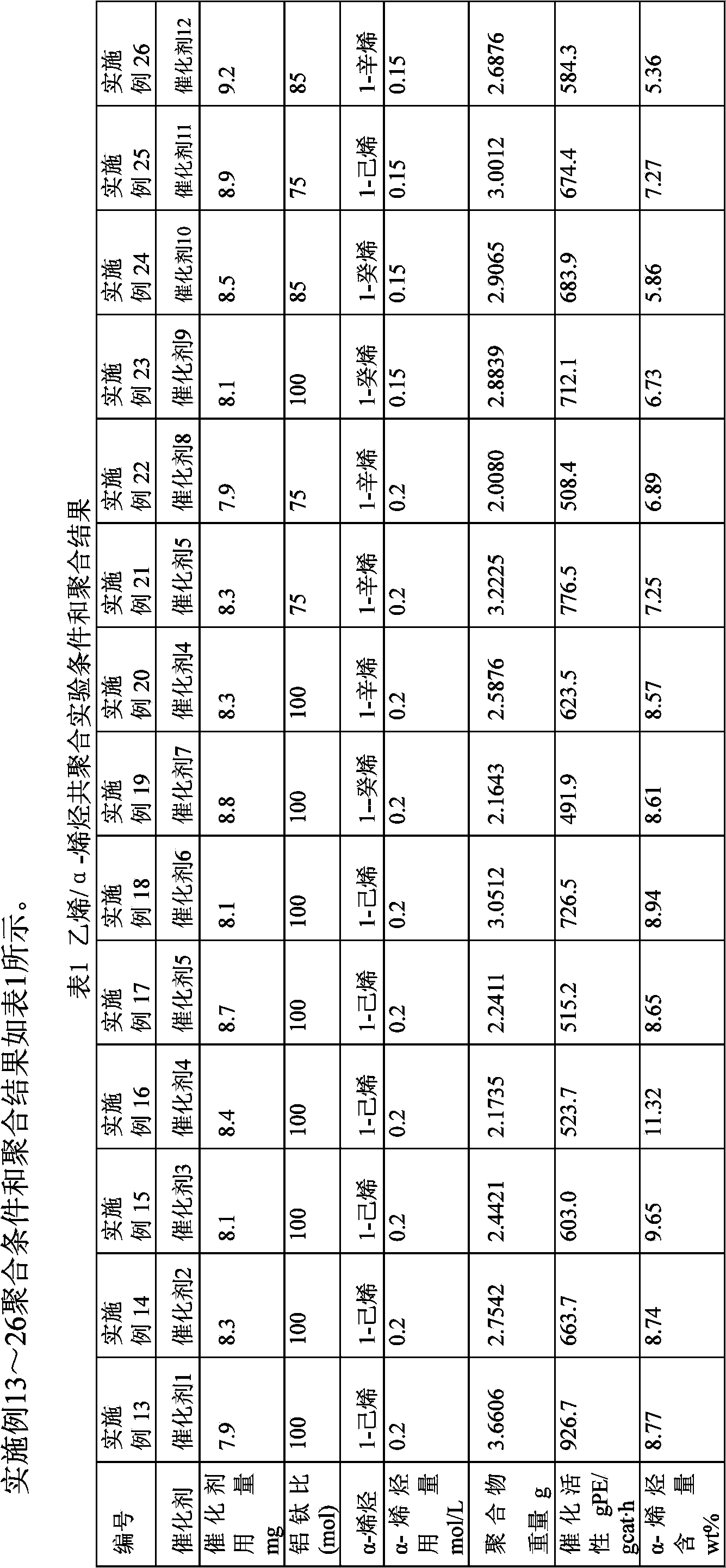

Examples

Embodiment 1

[0029] Catalyst 1 is prepared as follows:

[0030] (1) Add 1 g of anhydrous magnesium chloride, 30 ml of n-hexane and 3.75 ml of isobutanol into a three-neck flask replaced by argon, stir and heat to 70° C., and react for 3 hours to obtain a suspension.

[0031] (2) Add 0.05 ml of 2,2-dimethoxypropane to the suspension, stir and react at 70° C. for 1 hour, then add 0.3 ml of tetraethoxysilane, and stir and react at 70° C. for 1 hour.

[0032](3) Cool down to room temperature, slowly add 24 ml of titanium tetrachloride dropwise for 90 minutes; gradually raise the temperature to 70° C. for 2 hours; then stir and react for 2 hours.

[0033] (4) Hydraulically filter the supernatant, add 25 ml of n-hexane, heat up to 70°C, add 0.05 ml of tetraethoxysilane, stir and react for 1 hour; then add 0.025 ml of 2,2-dimethoxypropane, stir and react 1 hour.

[0034] (5) Then add 12 ml of titanium tetrachloride and react for 2 hours. After the reaction, it was washed with n-hexane for seve...

Embodiment 2

[0036] The preparation method of catalyst 2 is the same as embodiment 1, and difference is:

[0037] In step (1), add 35 ml of n-hexane and 2.50 ml of isobutanol to 1 g of anhydrous magnesium chloride, stir and heat to 70° C., and react for 5 hours.

[0038] In step (2), the amount of 2,2-dimethoxypropane is 0.10 ml, and the reaction time is 0.5 hours; the tetraethoxysilane is replaced by cyclohexylmethyldimethoxysilane, and the amount is 0.05 ml, and the reaction time is 2 hours.

[0039] In step (4), the amount of 2,2-dimethoxypropane used is 0.02 ml, and the reaction time is 2 hours.

[0040] The reaction time of titanium tetrachloride in step (5) is 3 hours.

[0041] The titanium content of the obtained solid catalyst 2 was 4.90%.

Embodiment 3

[0043] The preparation method of catalyst 3 is with embodiment 1, difference is:

[0044] In step (1), replace 30 ml of n-hexane with 35 ml of n-heptane, and replace 3.75 ml of isobutanol with 2.50 ml of n-hexanol, stir and heat to 90° C., and the reaction time is 2 hours.

[0045] Replace 2,2-dimethoxypropane with tetrahydrofuran in step (2), its consumption 0.20 milliliters, reaction time 2 hours; Replace tetraethoxysilane with 3-chloropropyl triethoxysilane, its consumption 0.40 milliliters, react Time 0.5 hours.

[0046] In step (3), the amount of titanium tetrachloride is 15 milliliters, the dropwise addition time is 2 hours, the temperature is raised to 90° C., and the reaction time is 1 hour.

[0047] Step (4) heats up to 90°C, replaces tetraethoxysilane with 3-chloropropyltriethoxysilane, the amount is 0.015 ml, and the reaction time is 2 hours; replaces 2,2-dimethoxypropane with tetrahydrofuran, the amount 0.15 ml, reaction time 0.5 hours.

[0048] The amount of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com