Preparation method of strontium ranelate key intermediate 3-ketoglutaric acid diethyl (dimethyl) ester

A technology of diethyl oxoglutarate and strontium ranelate, which is applied in the field of drug synthesis, can solve problems such as long production cycle, difficult handling, and high corrosion of equipment, so as to improve the reaction speed, shorten the reaction time, and reduce the cost of raw materials. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

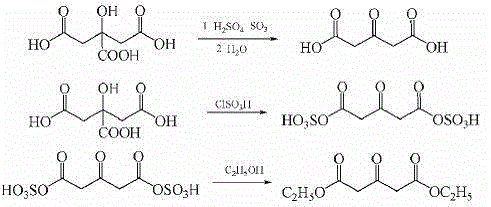

Method used

Image

Examples

Embodiment 1

[0017] Example 1: SO 4 2- / TiO 2 Type or S 2 o 8 2- / TiO 2 Preparation of solid super acid

[0018] Dissolve 3000 mL tetrabutyl titanate in 3000 mL absolute ethanol, add glacial acetic acid dropwise under stirring at room temperature, continue stirring after the addition, and then add 4500 mL concentration of 0.6 mol L -1 of (NH 4 ) 2 SO 4 or (NH 4 ) 2 S 2 o 8 solution, continue to stir, put the mixed solution in a water bath at 80 °C for sol-gel conversion, after the gel is aged, put it in a drying oven at 70 °C for 24 h to obtain a dry gel, crush it and place it at 600 °C Calcined for 3 h to obtain the desired solid acid catalyst sample.

Embodiment 2

[0019] Example 2: SO 4 2- / SnO 2 , SO 4 2- / ZrO 2 , SO 4 2- / ZnO,SO 4 2- / Fe 2 o 3 , S 2 o 8 2- / SnO 2 , S 2 o 8 2- / ZrO 2 , S 2 o 8 2- / ZnO, and S 2 o 8 2- / Fe 2 o 3 Preparation of Type Solid Superacid

[0020] at 10% Fe 2 (SO 4 ) 3 / SnCl 2 / ZnSO 4 / Zr(SO 4 ) 2 Add concentrated ammonia water to the aqueous solution, adjust the pH to 9-10, obtain a precipitate, wash it with water until it is neutral, dry it at 120°C, and then grind it to obtain a powder, pass it through a 100-mesh sieve, and use a concentration of 1 mol L -1 of (NH 4 ) 2 SO 4 or (NH 4 ) 2 S 2 o 8 The solution was soaked for 2 hours, dried at 120°C for 12 hours after centrifugation, and roasted at 600°C for 3 hours to obtain the desired SO 4 2- / SnO 2 , SO 4 2- / ZrO 2 , SO 4 2- / ZnO,SO 4 2- / Fe 2 o 3 , S 2 o 8 2- / SnO 2 , S 2 o 8 2- / ZrO 2 , S 2 o 8 2- / ZnO, and S 2 o 8 2- / Fe 2 o 3 type solid superacid catalyst samples.

Embodiment 3

[0021] Embodiment 3: the preparation of 3-oxoglutaric acid diethyl ester

[0022] Add 1400g of ethanol to a 10L three-neck flask, cool down to -5°C, and put in SO 4 2- / TiO 2 or S 2 o 8 2- / TiO 2 Add 140g of solid superacid catalyst, then add 700g of citric acid monohydrate and slowly raise the temperature. There are bubbles (carbon monoxide) during the heating process. Heat to 25°C for 1 hour of time-preservation reaction. After no obvious bubbles, heat to 50°C for 3 hours of time-preservation reaction, and filter The filtrate and filter cake are recovered from the solid super acid catalyst and applied mechanically. After the ethanol is recovered from the filtrate, the reaction solution is slowly poured into ice water (below 10°C), and 2000ml of dichloromethane is added to stir and stand for stratification. Take the organic phase, and the organic phase is bright yellow. , The water phase is slightly white and turbid, the water phase is extracted with 500mL×2 times of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com