Method for preparation of colored special-shaped elastic multifilament fiber by polyether ester/PTT composite spinning

A multifilament fiber, composite spinning technology, applied in the direction of conjugated synthetic polymer rayon, melt spinning, fiber processing, etc., can solve problems such as color toxicity, and achieve simple manufacturing process, uniform filament dryness, and smooth fabric. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 20-liter stirred vessel equipped with a column and a series condenser, 4.9 mol of terephthalic acid, 5.1 mol of butanediol, 0.7 mol of polyethylene oxide glycol solution with a molecular weight of 1200 and 0.6 mol of Molecular weight is the aqueous solution of 25% tetramethylammonium hydroxide that the meta-propylene oxide glycol of 2000, 2g PbSO4, 8ml weight percentage. After the nitrogen pressurization / purging cycle, and the heater temperature was adjusted so that the initial charge temperature was 190°C, the condensation valve was set at 115°C. The reaction mass was heated to 250° C., 25 g of polyisobutylene adipate with a molecular weight of 5000 was added, and the pressure valve was adjusted to reduce the pressure to 0.5 mmHg within 30 minutes. After 2 hours, the melt was extruded through a die under nitrogen pressure to obtain strands. The modified polyether ester blended with the amphiphilic high polymer can be obtained by pulling the wire through the water...

Embodiment 2

[0024] In a 20-liter stirred vessel equipped with a column and a series condenser, 5.4 mol of terephthalic acid, 5.2 mol of butanediol, 0.7 mol of polyethylene oxide glycol solution with a molecular weight of 1000 and 0.6 mol of Molecular weight is 1500 meta-propylene oxide glycols, 1.5g PbSO4, 5ml weight percent is the aqueous solution of 25% tetramethylammonium hydroxide. After the nitrogen pressurization / purging cycle, and the heater temperature was adjusted so that the initial charge temperature was 180°C, the condensation valve was set at 110°C. The reaction material was heated to 240° C., 20 g of polyisobutylene adipate with a molecular weight of 8000 was added, and the pressure valve was adjusted to reduce the pressure to 0.5 mmHg within 30 minutes. After 2 hours, the melt was extruded through a die under nitrogen pressure to obtain strands. The modified polyether ester blended with the amphiphilic high polymer can be obtained by pulling the wire through the water tank...

Embodiment 3

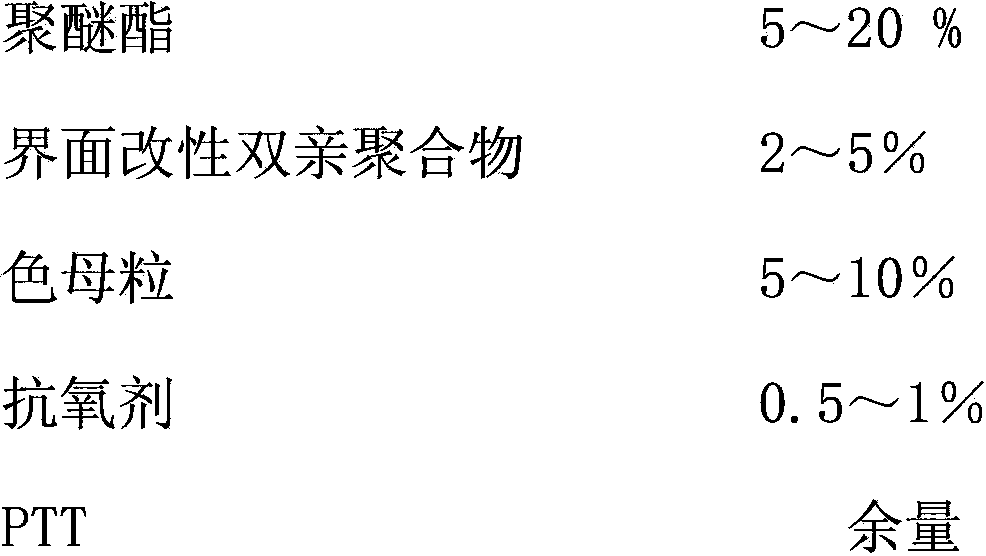

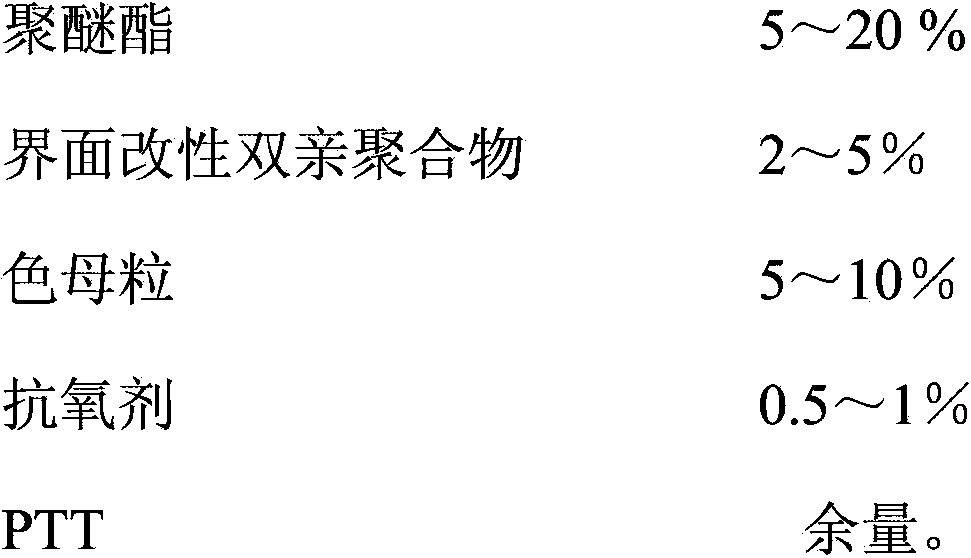

[0026] Use spinning chip to be by 80 parts of poly(trimethylene terephthalate) (PTT) spinning chip, 5 parts of color masterbatch and 14.5 parts of TPEE in embodiment one and amphiphilic polymer blending chip and 0.5 part of antioxidant, After screw blending, cut off the preparation, put the slices prepared by blending in the VC358 rotary pot, first evacuate to within 30 Pa, then heat to 120°C for 8 hours for drying and dehydration, keep the water content below 35PPM for 8 hours; color Masterbatch (Wuxi Changhong Chemical Plastic Color Granules Co., Ltd. fiber special masterbatch), gradually heated to 120°C for drying and dehydration in 8 hours, and kept warm for 8 hours. The mass ratio of color masterbatch and pigment is 30%, containing The water content is below 35PPM, and the drying process is a well-known technology in the industry. Using VC406 spinning machine, polyester chips and color masterbatch are extruded, blended and melted by a screw machine to form a melt, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com