Preparation method for regioselective biological-contamination resistant array chip

An anti-biological pollution, array chip technology, applied in the direction of biochemical equipment and methods, microbial measurement/inspection, biological testing, etc., can solve the problems of sample point diffusion, difficult control of array size, etc., achieve low equipment requirements, reduce non-special Effect of heterosexual adsorption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Example 1: A method for preparing a regioselective anti-biological contamination array chip

[0119] Will pass through Piranha solution (H 2 SO 4 / H 2 o 2 =4 / 1, v / v) After cleaning, place the 1cm×1cm silicon chip in 2% (v / v) methanol solution of 5-hexenyltrimethoxysilane, react at 25°C for 30 minutes, wash with methanol Clean and dry. The structure of 5-hexenyltrimethoxysilane is as follows:

[0120]

[0121] 40g / L methanol solution of 3-[[2-(methacryloyloxy)ethyl](dimethyl)-ammonium]-1-propanesulfonic acid (SBMA) betaine Spin-coat on the chip surface at a spin-coating speed of 2000 rpm for 10 seconds. The structure of SBMA betaine is:

[0122]

[0123]Spread a mask with an array pattern on the surface of the chip and transfer to 20mW / cm 2 and 365nm ultraviolet light for 3 minutes to initiate graft polymerization of SBMA betaine and the surface of the chip to form non-array regions. After washing with 50% aqueous methanol solution, 40g / L of anti-biofoulin...

Embodiment 2

[0126] Example 2: A method for preparing a regioselective anti-biological contamination array chip

[0127] Place a 1cm×1cm polydimethylsiloxane sheet in a 5% (v / v) ethanol solution of 3-(methacryloyloxy)propyltrimethoxysilane, react at 25°C for 2 hours, and use Wash with 50% aqueous methanol and dry. The structure of 3-(methacryloyloxy)propyltrimethoxysilane is:

[0128]

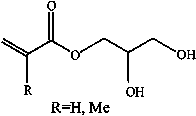

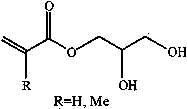

[0129] Spin-coat the methanol / water (methanol / water=1 / 1, v / v) solution of 30g / L anti-biological contamination monomer—glyceryl methacrylate monomer on the surface of the chip, the spin-coating speed is 1500 rpm, and the time is 60 seconds. The structure of glyceryl methacrylate is:

[0130]

[0131] Spread a mask with an array pattern on the surface of the chip and transfer to 20mW / cm 2 1. Under 365nm ultraviolet light, the ultraviolet light is irradiated on the surface of the chip through the mask for 5 minutes to trigger the graft polymerization of glycerol methacrylate and the surface of the ch...

Embodiment 3

[0134] Example 3: A method for preparing a regioselective anti-biological contamination array chip

[0135] Will pass through Piranha solution (H 2 SO 4 / H 2 o 2 =4 / 1, v / v) Cleaned 1cm×1cm glass slides were placed in 2% (v / v) 3-aminopropyltriethoxysilane toluene solution, reacted at 70°C for 5 hours, and washed with toluene Wash and dry under vacuum at 120°C for 1 hour. The structure of 3-aminopropyltriethoxysilane is:

[0136]

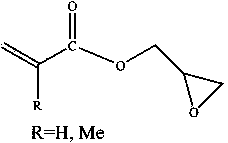

[0137] The chips were dipped in 10% (v / v) glycidyl methacrylate in acetone solution, reacted at 25°C for 8 hours, washed with acetone and dried. The structure of glycidyl methacrylate is:

[0138]

[0139] A methanol solution of 4% (v / v) anti-biofouling monomer-hydroxyethyl methacrylate was spin-coated on the chip surface at a spin-coating speed of 2500 rpm for 10 seconds. The structure of hydroxyethyl methacrylate is:

[0140]

[0141] Spread a mask with an array pattern on the surface of the chip and transfer to 15mW / cm 2 1. Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com