Preparation method of compound amino acid cheated nano-selenium leaf fertilizer

A compound amino acid and nano-selenium technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low element utilization rate, single nutrient composition, and unstable effect, and achieve rapid and thorough dissolution, easy absorption, and improved growth speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

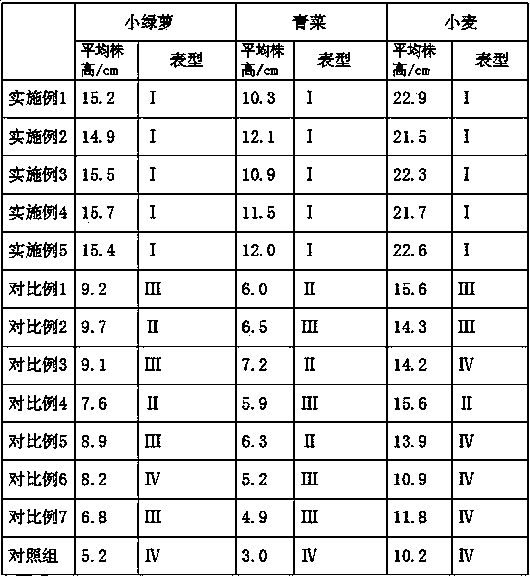

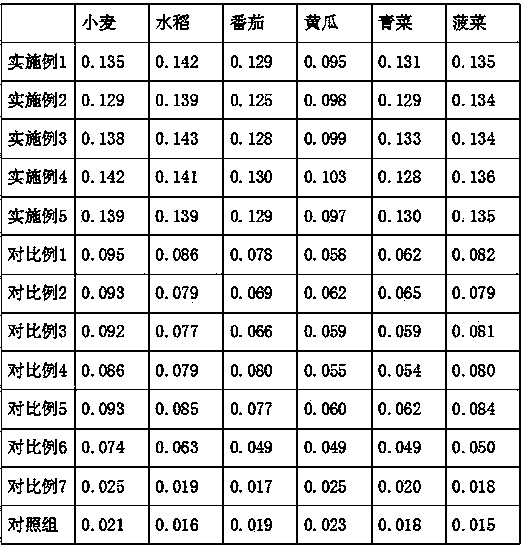

Examples

Embodiment 1

[0027] (1) Dissolve the porcine hemoglobulin powder with pure water at a mass volume ratio of 1:5 in the enzymatic hydrolysis irrigation, mix well, heat up to 50°, and use trypsin and papaya at a volume ratio of 3:1:0.5 Protease and flavor enzymes were used for enzymolysis to obtain an enzymolysis solution; the pH of the solution during enzymolysis was 8.0, and after 4.5 hours of enzymolysis, the temperature of the enzymolysis tank was raised to 90° to inactivate the enzyme for 30 minutes; (2) to Add sugar alcohol accounting for 3% of the total weight of the enzymolysis solution to the enzymolysis solution, react at 50°C for 1 hour, then lower the temperature to 20°C and keep it for 10 minutes to obtain a reaction solution; the sugar alcohol has a mixing ratio of 1 :5: 3:1 sugar alcohol mixture of mannitol, sorbitol, xylitol and glyceritol; (3) adding nano-selenium and citric acid accounting for 0.3% of the total weight of the reaction solution to the reaction solution As a ch...

Embodiment 2

[0029] (1) Dissolve bovine or sheep hemoglobulin powder with pure water at a mass-volume ratio of 1:7 in the enzymatic perfusion, mix well, heat up to 65°, and use trypsin with a volume ratio of 2:1.5:0.75 , papain and flavor enzymes for enzymolysis to obtain an enzymolysis solution; during enzymolysis, the pH of the solution was 8.5, and after 5.5 hours of enzymolysis, the temperature of the enzymolysis tank was raised to 95 ° for enzymatic treatment, and the enzymatic deactivation was 20 minutes; (2 ) Add sugar alcohol accounting for 5% of the total weight of the enzymolysis solution to the enzymolysis solution, react at 70°C for 1 hour, then lower the temperature to 30°C and keep it for 10 minutes to obtain a reaction solution; the sugar alcohol is the mixing ratio A 3:2:1:3 sugar alcohol mixture of mannitol, sorbitol, xylitol and glyceritol; (3) adding nano-selenium and 0.1% of the total weight of the reaction solution to the reaction solution Malic acid is used as a chela...

Embodiment 3

[0031] (1) Dissolve chicken or duck hemoglobulin powder with pure water at a mass volume ratio of 1:3 in enzymatic hydrolysis, mix well, heat up to 55°, and use trypsin at a volume ratio of 1:2:1 , papain and flavor enzymes for enzymolysis to obtain an enzymolysis solution; during enzymolysis, the pH of the solution was 8.3, and after 5 hours of enzymolysis, the temperature of the enzymolysis tank was raised to 90 ° for enzymatic treatment, and the enzymatic deactivation was 20 minutes; (2 ) Add sugar alcohol accounting for 4% of the total weight of the enzymolysis solution to the enzymolysis solution, react at 60°C for 1.5h, then lower the temperature to 30°C and keep it for 20min to obtain a reaction solution; the sugar alcohol is mixed A sugar alcohol mixture of mannitol, sorbitol, xylitol and glycerol with a ratio of 2:3:2:2; (3) adding nano-selenium to the reaction solution and accounting for 0.1% of the total weight of the reaction solution malic acid and 0.05% lactic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com