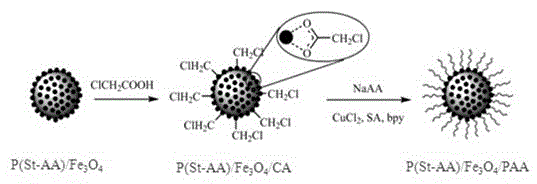

Polymer-brush-modified magnetic composite microsphere as well as preparation method and application thereof

A technology of magnetic composite microspheres and polymer brushes, applied in the field of biomaterials, can solve the problems of rough separation, limited separation effect, and poor target-specific binding ability, and achieve narrow particle size distribution, reduce magnetic shielding effect, and improve The effect of the ability to specifically bind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

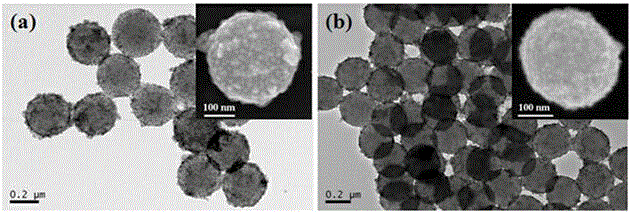

[0047] Example 1 Superparamagnetic Fe 3 o 4 Preparation of nanoparticles

[0048] Preparation of Fe by Polyol Method 3 o 4 Nanoparticles: Put 720 mg of iron acetylacetonate in a 100 mL three-neck flask with a condenser, vacuumize and blow nitrogen three times, and then inject 40 mL of triethylene glycol into the reaction system. Magnetic stirring, heating in a sand bath, slowly raising the temperature to 180°C, and keeping it warm for 30 minutes; then rapidly raising the temperature to 278°C (the boiling point of triethylene glycol), and refluxing for 30 minutes to obtain a black magnetic fluid (ie, Fe 3 o 4 original reaction solution of nanoparticles). Cool to room temperature, wash with ethanol : ethyl acetate (V1 : V2=1 : 10) mixed solution repeatedly three times, magnetically separate, and redisperse the product in ethanol, store at low temperature.

[0049] The obtained product has good superparamagnetism, the average particle size is 4-20nm, and the specific satu...

Embodiment 2

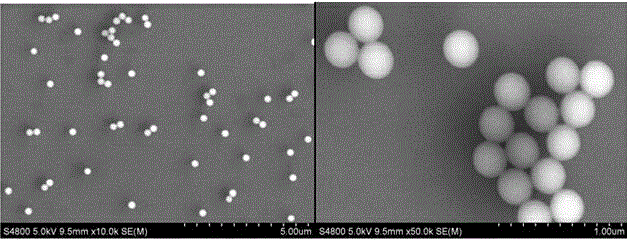

[0051] Example 2 Superparamagnetic Composite Microspheres P(St-AA) / Fe 3 o 4 preparation of

[0052] The polymer template is prepared by a soap-free emulsion polymerization method, as follows: a three-necked bottle, mechanical stirring, vacuuming and nitrogen flow are repeated three times to ensure that the reaction system is anhydrous and oxygen-free. Styrene monomer (St, 0.5 g) and distilled water (45 mL) were injected into the reaction system, emulsified at 350 rpm for 30 min under nitrogen protection. Heat the oil bath to 70°C, add a persulfate (such as ammonium persulfate APS) aqueous solution as an initiator (APS content is 3.3 mg), and react for 3 h. Then, styrene (4.5 g), acrylic acid (1.67 g), and water (5 mL) were injected into the reaction system respectively, and the reaction was continued for 5 h. After the reaction, a white emulsion was formed. After cooling to room temperature, the reaction solution was distilled under reduced pressure to remove unreacted m...

Embodiment 3

[0057] Example 3 Preparation of Superparamagnetic Composite Microspheres

[0058] Take the three-necked bottle, stir it mechanically, assemble the reaction device, and repeat three times of vacuuming and blowing nitrogen to ensure that the reaction system is anhydrous and oxygen-free. Styrene monomer (St, 0.5 g) and distilled water (45 mL) were injected into the reaction system, emulsified at 400 rpm for 40 min under nitrogen protection. Heat the oil bath to 70 ℃, add persulfate (such as sodium persulfate) aqueous solution as the initiator (sodium persulfate content is 3 mg), reaction: ethyl acetate (V1 : V2 = 1 : 10) mixed solution repeatedly washed three times , magnetic separation, and the resulting product was redispersed in ethanol and stored at low temperature.

[0059] The obtained product has good superparamagnetism, the average particle size is 4-20nm, and the specific saturation magnetization is higher than 50 emu / g.

[0060] High temperature method (see JACS 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com