Composite material of high-nitrogen-doped grapheme and ultrathin MoSe2 nanosheets and preparation method of composite material

A technology of nitrogen-doped graphene and composite materials, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficulties and few researches, and achieve simple operation, controllable reaction conditions and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

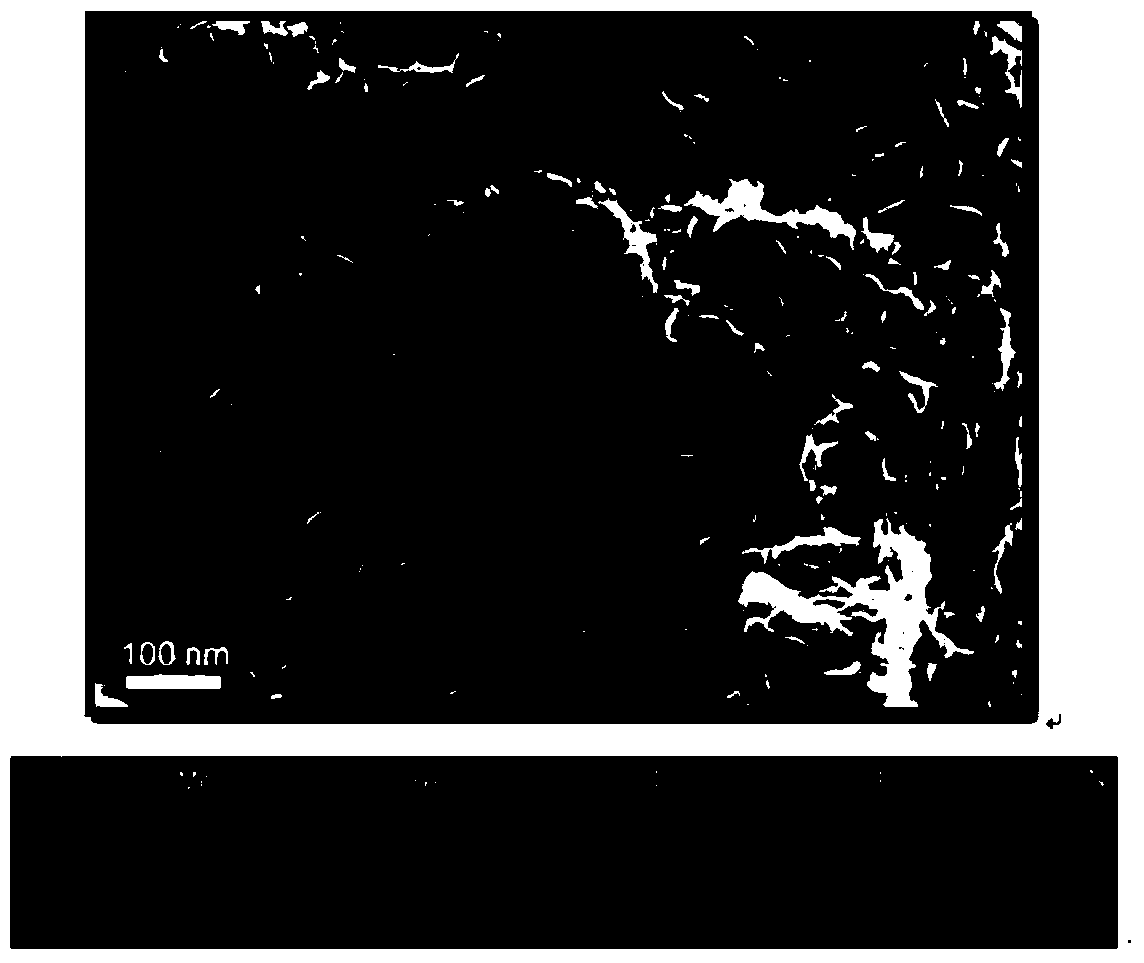

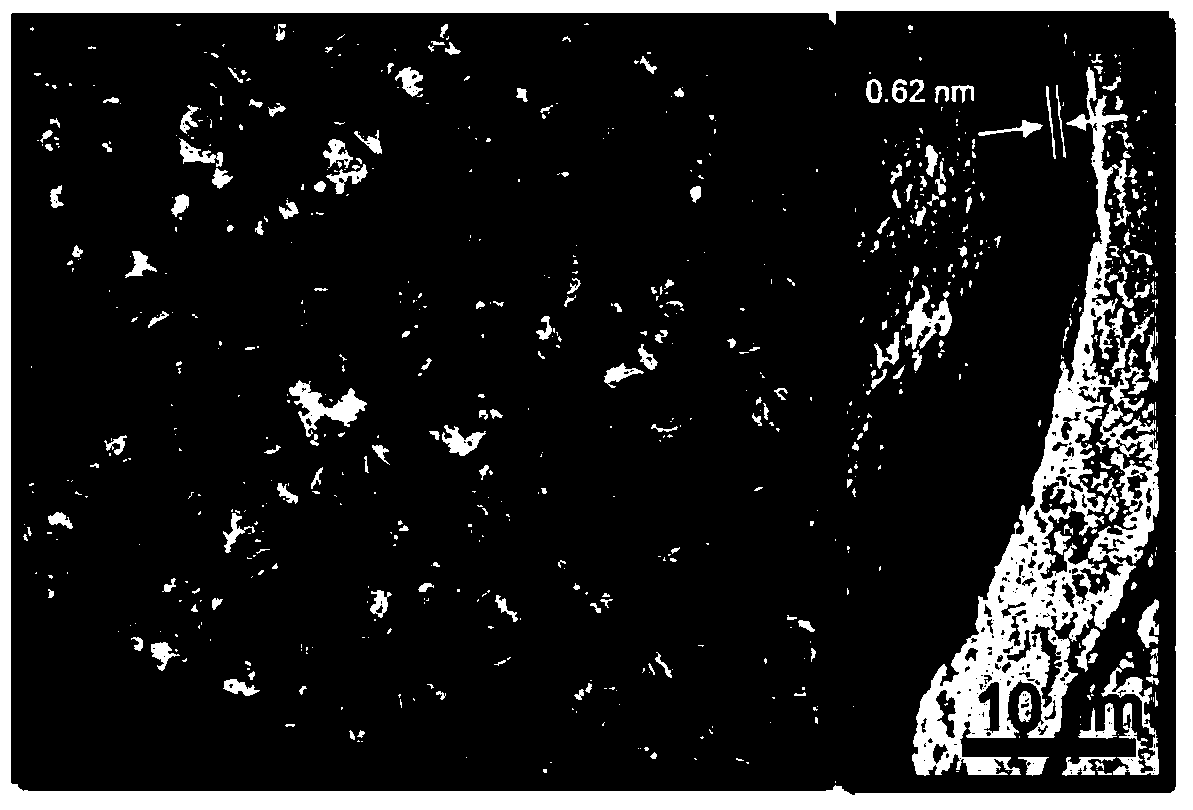

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and ultrasonically disperse it evenly; then add 5 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 2 hours, to obtain rough low-nitrogen graphene; finally, obtain low-nitrogen graphene with excellent quality through dialysis.

[0031] 2) Preparation of chemical reaction solution: 0.2mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 3mmol of Na 2 SeO 3 dissolved in 15mL H 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0032] Add 5 mL of ethylenediamine (ETA) stabilizer to the above solution, stir for 15 minutes; get 5 low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0033] 3) Solvothermal hig...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 10 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0037] 2) Preparation of chemical reaction solution: 0.5 mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 10mmol of Na 2 SeO 3 dissolved in 15mL H 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0038] Add 15mL of ethylenediamine (ETA) stabilizer to the above solution, stir for 15 minutes; get 15mL of low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0039] 3) Solvothermal high nitr...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 15 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0043] 2) Preparation of chemical reaction solution: 1.5mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 15mmol of Na 2 SeO 3 dissolved in 15mL H 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0044] Add 25mL of ethylenediamine (ETA) stabilizer to the above solution, stir for 15 minutes; get 20mL of low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0045] 3) Solvothermal high nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com