A kind of ultra-thin heat-resisting heat-resisting coating

A technology for thermal insulation coatings and high temperature resistance, which can be used in anti-corrosion coatings, anti-fouling/underwater coatings, radiation-absorbing coatings, etc. Small shrinkage coefficient, good chemical stability and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

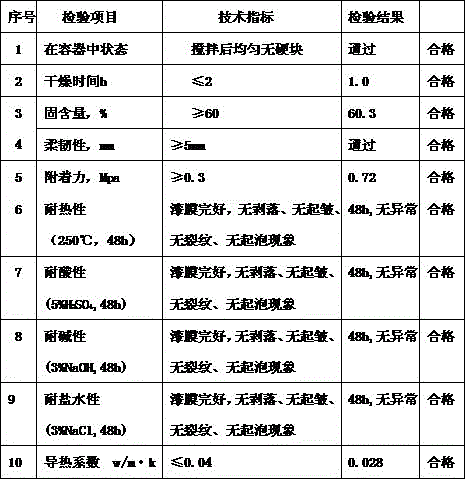

Embodiment 1

[0025] Example 1, 180 parts of a mixture of special monomer-modified self-crosslinking acrylate copolymer and pure acrylic resin emulsion (each accounting for 50%), 20 parts of iron oxide red with a refractive index of 2.0 or more, 50-100 μm 65 parts of hollow ceramic microspheres, 2 parts of cerium oxide, 25 parts of additives (including 1 part of dispersant, 15 parts of film-forming aid, 2 parts of bactericide, 2 parts of ammonia water, and 5 parts of thickener) and 200 parts of purified water The above parts are all parts by weight. The special monomer-modified self-crosslinking acrylate copolymer is prepared by using ammonium methylol acrylate and acrylic acid as active monomers and using seed emulsion polymerization. First add water to the stirring tank by weight, then add the dispersant, suck the pigment and filler through the vacuum pump, stir and disperse for 45 minutes at a rotating speed (550 rpm) to make a slurry; then adjust the rotating speed of the stirring tank t...

Embodiment 2

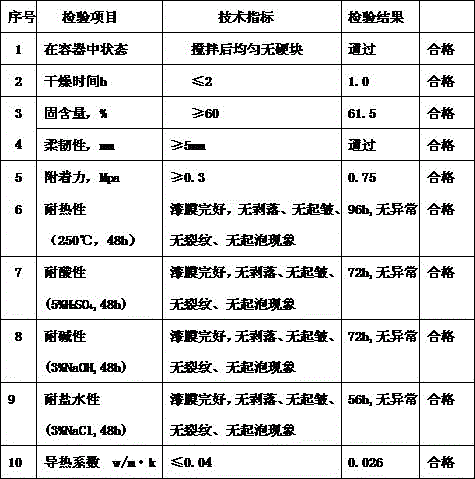

[0028] Example 2, using 270 parts of a mixture of special monomer modified self-crosslinking acrylate copolymer and silica sol (acidic) (wherein the number of silica sol accounts for 30%), iron oxide red and titanium dioxide with a refractive index of 2.0 or more A total of 15 parts (each accounted for 50%), 55 parts of 100-250μm power plant drift beads, 3 parts of cerium oxide and yttrium oxide (including 2 parts of cerium oxide), 36 parts of additives (including 2 parts of dispersant, component 20 parts of film aid, 2 parts of bactericide, 2 parts of ammonia water, 10 parts of thickener) and 270 parts of purified water, the above parts are parts by weight, the special monomer modified self-crosslinking acrylate copolymer It is prepared by using methylol acrylic acid amide and acrylic acid as active monomers and using seed emulsion polymerization. First add water to the stirring tank by weight, then add the dispersant, suck the pigment and filler through the vacuum pump, stir...

Embodiment 3

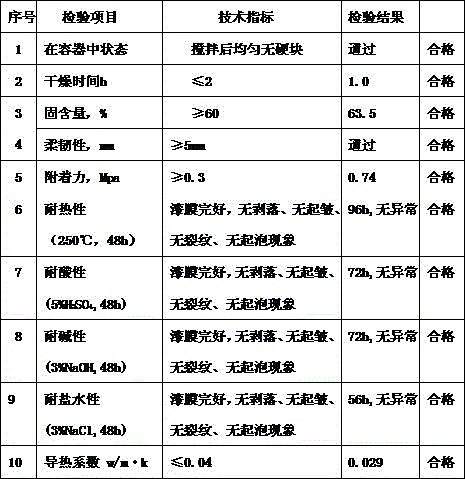

[0031]Example 3, 100 parts of a mixture of special monomer-modified self-crosslinking acrylate copolymer, pure acrylic resin emulsion and lithium silicate (wherein the number of pure acrylic resin emulsion accounts for 20%, and the number of lithium silicate accounts for 30%) %), a total of 28 parts of iron oxide red and carbon black with a refractive index above 2.0 (each accounting for 50%), 100-250μm hollow glass microspheres and hollow ceramic microspheres 76 parts (each accounting for 50%), oxidation 1.5 parts of cerium and lanthanum oxide (including 1 part of cerium oxide), 15 parts of additives (including 2 parts of dispersant, 7 parts of film-forming aid, 1 part of bactericide, 2 parts of ammonia water, and 3 parts of thickener) and pure 120 parts of water, the above parts are all parts by weight. The special monomer modified self-crosslinking acrylate copolymer is prepared by using ammonium methylol acrylate and acrylic acid as active monomers and using seed emulsion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com