A method for preparing high-conductivity carbon materials by hydrothermal method

A high-conductivity, carbon material technology, applied in the field of hydrothermal preparation of high-conductivity carbon materials, can solve the problems of increasing the environmental load reaction cost, increasing the reaction cost and load, and requiring higher reaction conditions, and increasing market application prospects. and economic benefits, abundant raw materials, and shortened reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

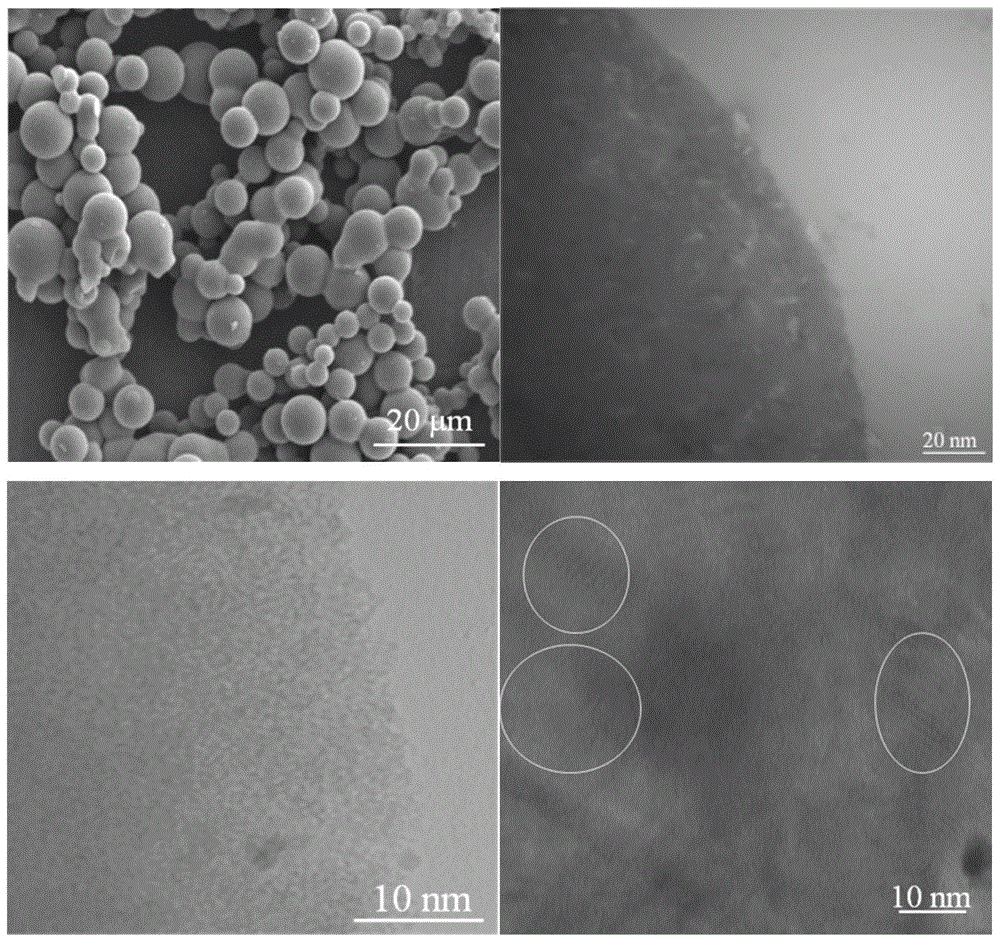

Image

Examples

Embodiment 1

[0023] Add 3.0g carboxymethyl cellulose to 40mL aqueous solution, use urea as the nitrogen source, the concentration is 2%, put polytetrafluoroethylene in the reaction kettle, ensure that the volume of the solution and the volume of the kettle are 6:7, 5℃ / The heating rate was raised to the target temperature of 220°C at a heating rate of 12 hours, and the temperature was kept constant for 12 hours, cooled down to room temperature, and centrifuged at 8000r / min for 3 times to obtain a brown solid product. It was washed with distilled water and absolute ethanol three times successively, and vacuum-dried at 105 °C for 12 h to obtain a nitrogen-doped hydrothermal carbon product precursor. Put the dried carbon into a tubular resistance furnace, raise the temperature at 5°C / min to the target temperature of 900°C, and keep the temperature for 2 hours to obtain powdered carbon materials. 2 The specific surface area of the carbon material prepared by the adsorption instrument test is...

Embodiment 2

[0026] Add 2.0g carboxymethyl cellulose to 40mL aqueous solution, use urea as nitrogen source, the concentration is 3.5%, put polytetrafluoroethylene in the reaction kettle, ensure that the volume of the solution and the volume of the kettle are 9:10, 5℃ / The heating rate was raised to the target temperature of 250°C at a heating rate of 10 min, and the temperature was kept constant for 10 h, cooled down to room temperature, and centrifuged twice at a speed of 12000 r / min to obtain a brown solid product. It was washed with distilled water and absolute ethanol three times successively, and vacuum-dried at 90°C for 12 hours to obtain a nitrogen-doped hydrothermal carbon product precursor. Put the dried carbon into a tubular resistance furnace, raise the temperature at 5°C / min to the target temperature of 850°C, and keep the temperature constant for 2 hours to obtain powdered carbon materials. 2 The specific surface area of the carbon material prepared by the adsorption instrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com