A kind of super weather-resistant fluorocarbon coating and preparation method thereof

A fluorocarbon coating and super weather-resistant technology, which is applied in coatings and other directions, can solve problems such as endangering workers' health, damaging the environment, and providing support for weather resistance, and achieves the effect of improving coating adhesion, weather resistance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

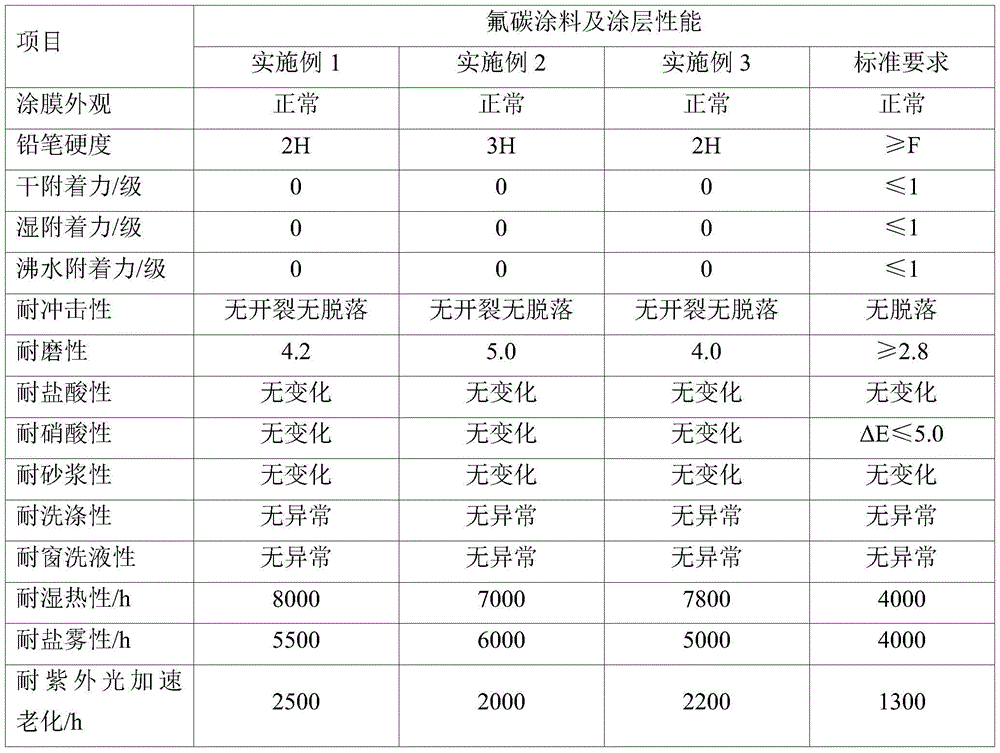

Embodiment 1

[0027] 90g parts of modified acrylic resin (the ratio of methyl methacrylate monomer, ethyl acrylate monomer, and hydroxyethyl acrylate monomer is 2:2:1) is dissolved in 210g butyl acetate to prepare a solid mass content of 300g of 30.00% resin solution; mix and grind the above 300g resin solution with 70g titanium dioxide, 20g cobalt blue, 10g carbon black, 100g talc, 5g defoamer, 5g dispersant, and 90g dimethyl phthalate until The fineness is ≤30μm, and the color paste is prepared by filtering with a 100 mesh filter to obtain 500g of color paste; 300g of polyvinylidene fluoride Add 33g of dimethyl phthalate to the above 500g color paste, stir and disperse uniformly at a stirring speed of 2000rpm; filter with a 300-mesh filter to obtain the super weather-resistant fluorocarbon coating of the present invention.

[0028] The above fluorocarbon topcoat was diluted to 50% solid content, coated on a steel plate pre-coated with acrylic primer with an 80 μm wire rod coater, and baked i...

Embodiment 2

[0031] 180g portions of modified acrylic resin (the ratio of methyl methacrylate and ethyl acrylate is 3:1) is dissolved in 180g ethyl acetate to prepare 360g resin solution with a solid mass content of 50.00%; the above 360g resin solution is combined with 50g titanium dioxide, 200g calcium carbonate, 5g dispersant, 15g leveling agent, 50g dimethyl succinate, 50g dimethyl glutarate, 50g dimethyl adipate are mixed and ground to a fineness of ≤30μm. 700g of color paste prepared by filtration with 200 mesh filter; 160g of polyvinylidene fluoride resin Add 36 g of dimethyl succinate to the above 700 g color paste, stir and disperse uniformly, at a stirring speed of 1000 rpm; filter with a 200-mesh filter to obtain the super weather-resistant fluorocarbon coating of the present invention.

[0032] Dilute the above fluorocarbon topcoat to 40% solid content, use an automatic knife coater to coat it on the aluminum plate pre-coated with amino resin primer, control the wet film thickness...

Embodiment 3

[0035] Dissolve 90g parts of modified acrylic resin (the ratio of methyl methacrylate to ethyl acrylate is 1:3) in 100g butyl acetate and 35g dimethyl phthalate to prepare a resin with a solid mass content of 40.00% 225g solution; mix the above 225g resin solution with 150g titanium dioxide, 50g molybdenum bismuth yellow, 100g barium sulfate, 50g diethyl succinate, 100g dimethyl glutarate, mix and grind to a fineness ≤30μm, filter with 400 mesh 600g color paste prepared by mesh filtration; 240g polyvinylidene fluoride resin Add 49g of dimethyl phthalate to the above-mentioned 600g color paste, stir and disperse uniformly at a stirring speed of 3000rpm; filter with a 100-mesh filter to obtain the super weather-resistant fluorocarbon coating of the present invention.

[0036] Dilute the above-mentioned fluorocarbon topcoat to 30% solid content, spray it on the aluminum plate pre-coated with fluorocarbon primer with a spray gun, and control the wet film thickness to 120μm, then put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com