Low-resistance high-efficiency lead-free back silver pulp for amorphous silicon solar battery

A solar cell, low-resistance and high-efficiency technology, applied in the field of solar energy, can solve the problems of rising series resistance of cells, high series resistance of cells, weak ability to form alloys or eutectics, etc., to improve thermal expansion and contraction performance, and improve photoelectric conversion Efficiency, the effect of reducing the probability of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the present invention comprises the following steps:

[0026] (1) Preparation of inorganic binder

[0027] Weigh the components of the glass powder according to different proportions, put them into the mixer and mix them for 50 minutes, let them stand for 30 minutes, pack them into corundum crucibles, and dry them for 150 minutes at 130°C. Put the dried powder into a horse boiling furnace, and smelt it at 1200°C for 60 minutes to obtain a homogeneous molten glass. The high-temperature glass liquid is extracted with deionized water to obtain block glass. After drying at 150°C, the glass block is ground to below 4 microns to obtain glass powder.

[0028] Mix glass powders with different properties according to a certain ratio, and disperse them with a powder machine at high speed for 3 to 10 minutes to obtain an inorganic binder.

[0029] (2) Preparation of organic binder

[0030] Weigh the organic solvent according to the proportion of the form...

Embodiment 1

[0035] (1) Preparation of organic binder

[0036] Prepare organic solvent, weigh 80g terpineol, 5g diethylene glycol butyl ether, 5g ethyl cellulose, add plasticizer (2g stearic acid, 2g acetyl tributyl citrate, 3g phthalate) , and the remainder was filled up to 100g with butyl carbitol acetate. and heated to 120° C., dissolved for 3 hours to obtain an organic binder, which is set aside.

[0037] (2) Preparation of inorganic binder

[0038] Weigh 60g of B 2 o 3 -SiO 2 -ZnO system lead-free glass binder (softening temperature is 650°C), 40g of Bi 2 o 3 -B 2 o 3 -SiO 2 System lead-free glass binder (softening temperature is 440°C), mix glass powders with different properties in a certain proportion, disperse at high speed with a powder machine for 3-10 minutes, and obtain 100g of inorganic binder.

[0039] (3) Preparation of lead-free back silver paste

[0040] Weigh 6g of inorganic binder, 55g of which has an average particle size of 5μm and a specific surface area o...

Embodiment 2

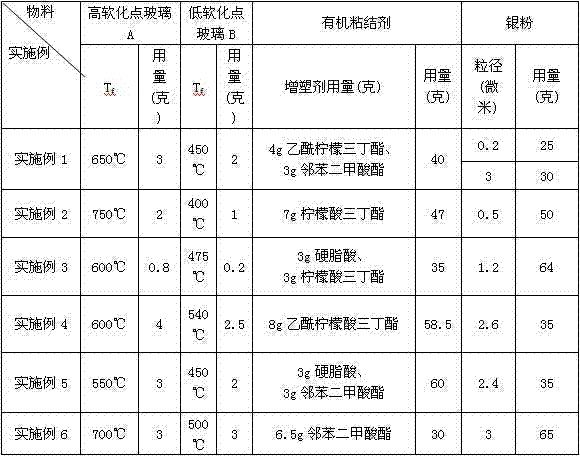

[0041] Embodiment 2, embodiment 3, embodiment 4, embodiment 5, embodiment 6, the specific preparation method is the same as embodiment 1, and its formula ratio adjusts according to following table 1-3 formula.

[0042] Table 1

[0043]

[0044] Table 2 A glass powder composition

[0045]

[0046] Table 3 B glass powder composition

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com