A kind of preparation method of self-dulling resin

A self-extinction and resin technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of material aging resistance, poor medium resistance, poor mechanical strength of coating films, etc., and achieve low preparation costs and synthesis The method is simple and the price is cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

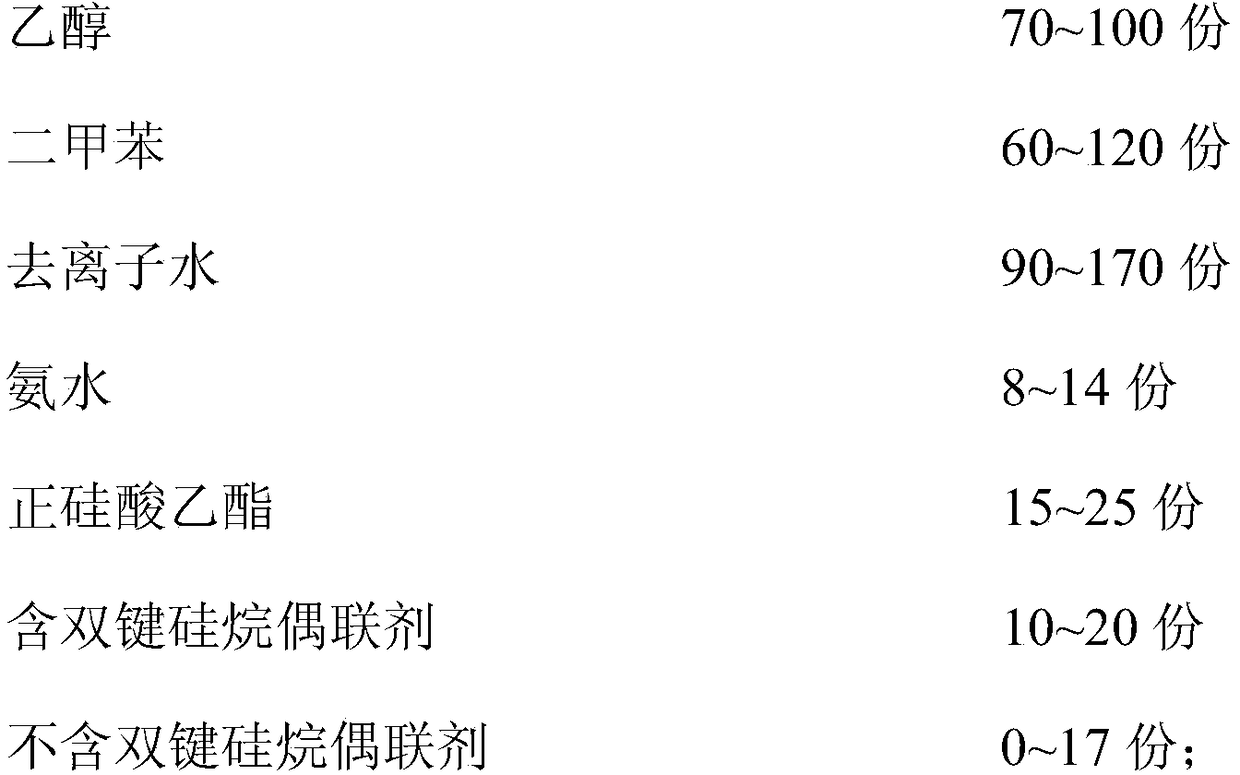

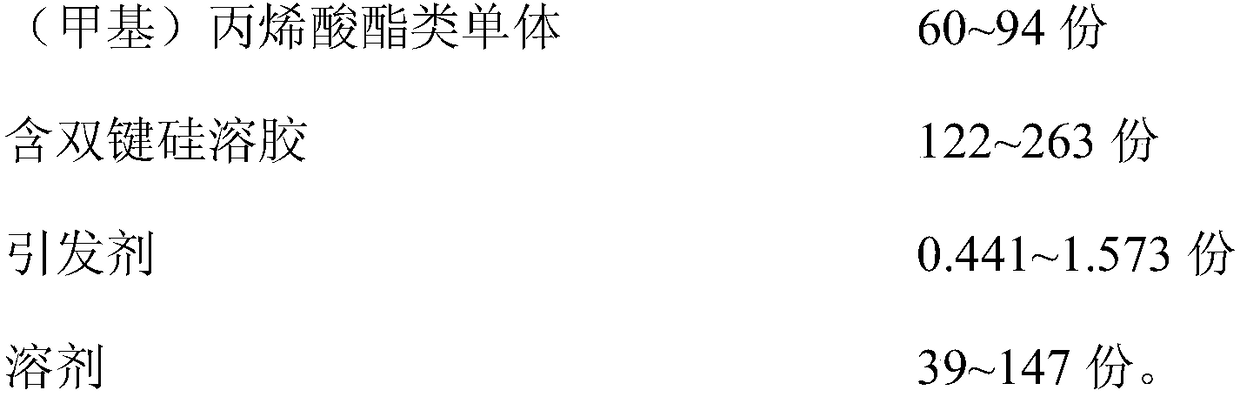

Method used

Image

Examples

Embodiment 1

[0031] A. Add 70g of ethanol and 80g of deionized water to the reaction flask, adjust the pH to 9-11 with 10g of ammonia water, raise the temperature to 50°C under the protection of nitrogen, and start adding 17g of 3-(methacryloyloxy)propylmethyl dropwise The mixture of dimethoxysilane, 15g of tetraethyl orthosilicate and 74g of xylene was added dropwise for 1 hour, then kept for 1 hour, cooled, and discharged for later use.

[0032] B. Mix 266g of double bond-containing silica sol and 100g of butyl acetate in the reaction flask to obtain the reaction product obtained in step A; under the condition of nitrogen protection, reflux to remove the water and ethanol in step A, and then drip at 85°C Add a mixture containing 32g of butyl acrylate, 16g of methyl methacrylate resin, 32g of 2-hydroxypropyl methacrylate, and 2g of benzoyl peroxide, drop it in 2.5 to 3 hours, and keep it warm for 2 hours; Benzoyl 0.15g, another initiator benzoyl peroxide 0.15g was added after 1 hour of he...

Embodiment 2

[0034] A. Add 90g of ethanol and 120g of deionized water to the reaction flask, adjust the pH to 9-11 with 11g of ammonia water, raise the temperature to 50°C under the protection of nitrogen, and start adding 10g of 3-(methacryloyloxy)propylmethyl dropwise Dimethoxysilane, 5g of γ-methacryloxypropyltrimethoxysilane, 16g of tetraethyl orthosilicate and 90g of xylene are added dropwise for 5 hours, then kept for 3 hours, cooled, and discharged for later use.

[0035] B. Mix 342g of double bond-containing silica sol and 70g of xylene as the reaction product obtained in step A evenly in a reaction flask; under nitrogen protection conditions, reflux to remove water and ethanol in step A, and then add A mixture containing 27g of styrene, 19g of lauryl methacrylate, 24g of 2-hydroxyethyl acrylate, and 2.4g of tert-butyl hydroperoxide, dripping in 3 to 4 hours, and keeping it warm for 3 hours; add initiator tert-butyl peroxide Hydrogen 0.16g, another initiator tert-butyl hydroperoxid...

Embodiment 3

[0037] A. Add 77g of ethanol and 100g of deionized water to the reaction flask, adjust the pH to 9-11 with 13g of ammonia water, raise the temperature to 50°C under the protection of nitrogen, and start adding 17g of γ-methacryloxypropyl trimethoxy Silane, 20g tetraethyl orthosilicate, 5g anilinomethyltriethoxysilane and 70g xylene mixture were added dropwise for 3 hours, then kept for 2 hours, cooled, and discharged for later use.

[0038] B. Mix 302g of the reaction product containing double bond silica sol and 84g toluene in the reaction flask obtained in step A; A mixture of 9 g styrene, 6 g acrylic acid, 19 g butyl methacrylate, 10 g 2-hydroxyethyl methacrylate, 10 g 2-hydroxypropyl methacrylate, 19 g vinyl acetate, 2.25 g benzoyl peroxide , after 2.5-3 hours, keep warm for 2 hours; add 0.25 g of initiator benzoyl peroxide, add another 0.25 g of initiator benzoyl peroxide after 1.5 hours of heat preservation; heat up to 115 ° C for 1.5 hours, cool down The material is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com