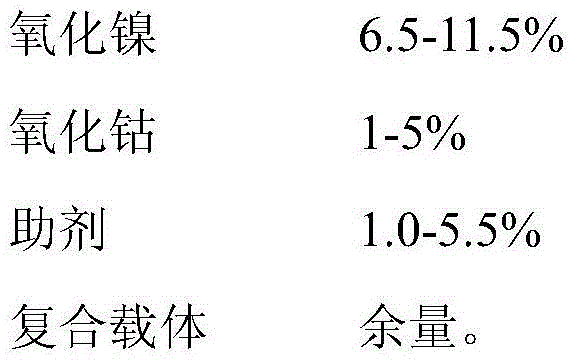

Complex nano-catalyst for preparing synthesis gas by reforming methane and carbon dioxide, and preparation method thereof

A carbon dioxide and nano-composite technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst bed blockage, activity decline, and high price , to achieve good activity and stability, increase active centers, and high surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

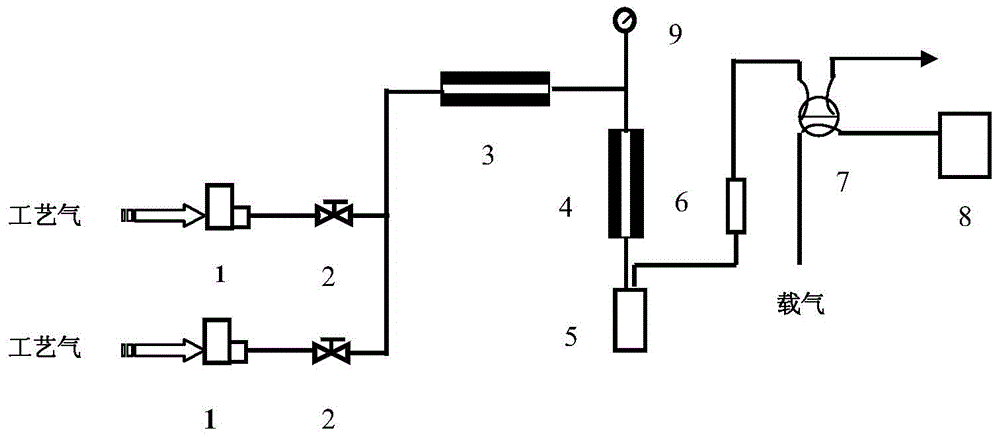

Method used

Image

Examples

Embodiment 1

[0037] Weigh 57g of aluminum nitrate, 40.5g of zirconium nitrate, 4.1g of cobalt acetate, and 0.42g of lanthanum nitrate, dissolve them in 500ml of water and stir for 10min to obtain solution A. Weigh 72g of urea, 16ml of ammonia water and dissolve in 500ml of water, then add 14.2g of basic nickel carbonate to obtain solution B. Solution A and solution B were mixed uniformly in an ultrasonic oscillator in parallel flow, the frequency of the ultrasonic wave was 25 kHz, and the mixed solution C was obtained by oscillating for 15 minutes. Move the solution C to a microwave reactor with a filling volume of no more than 80%, heat it at 180°C for 30 minutes, cool it down to room temperature naturally, pour it into a centrifuge for washing, and dry it at 120°C for 24 hours. The obtained catalyst powder was mixed with 0.8g of scallop powder and 0.7g of citric acid, extruded and roasted, heated to 400°C at a rate of 2°C / min, roasted at a constant temperature for 2 hours, and then roast...

Embodiment 2

[0039]Weigh 40.5g of zirconium nitrate, 1.1g of cobalt acetate, 0.85g of lanthanum nitrate, and 39.6g of colloidal silica, dissolve them in 500ml of water and stir for 20min to obtain solution A. Weigh 60g of urea, 12ml of ammonia water and dissolve in 500ml of water, then add 10.5g of basic nickel carbonate to obtain solution B. Solution A and solution B were mixed uniformly in an ultrasonic oscillator in parallel flow, the frequency of the ultrasonic wave was 45 kHz, and the mixed solution C was obtained by oscillating for 20 minutes. Move the solution C to a microwave reactor with a filling volume of no more than 80%, heat it at 160°C for 15 minutes, cool it down to room temperature naturally, pour it into a centrifuge for washing, and dry it in vacuum at 80°C for 36 hours. The obtained catalyst powder was mixed with 0.7 g of scallop powder and 0.6 g of citric acid, extruded and roasted, heated to 400 °C at a rate of 1 °C / min, roasted at a constant temperature for 2 hours, ...

Embodiment 3

[0041] Weigh 104g of aluminum nitrate, 40.5g of zirconium nitrate, 5.9g of cobalt sulfate, and 2.33g of lanthanum nitrate, dissolve them in 500ml of water and stir for 15min to obtain solution A. Weigh 89.7g of urea, 18ml of ammonia water and dissolve in 500ml of water, then add 18.2g of basic nickel carbonate to obtain solution B. Solution A and solution B were mixed uniformly in an ultrasonic oscillator in parallel flow, the frequency of the ultrasonic wave was 30 kHz, and the mixed solution C was obtained by oscillating for 25 minutes. Move the solution C to a microwave reactor with a filling volume of no more than 80%, heat it at 100°C for 60 minutes, cool it down to room temperature naturally, pour it into a centrifuge for washing, and dry it in vacuum at 80°C for 72 hours. The obtained catalyst powder was mixed with 1.2 g of scallop powder and 0.9 g of citric acid, extruded and roasted, heated to 450 ° C at a rate of 2 ° C / min, roasted at a constant temperature for 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com