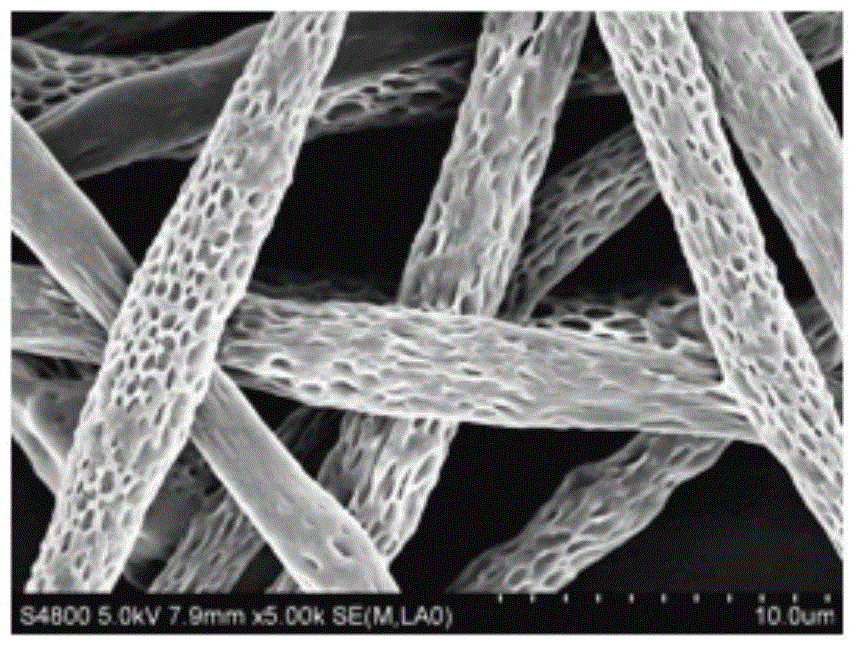

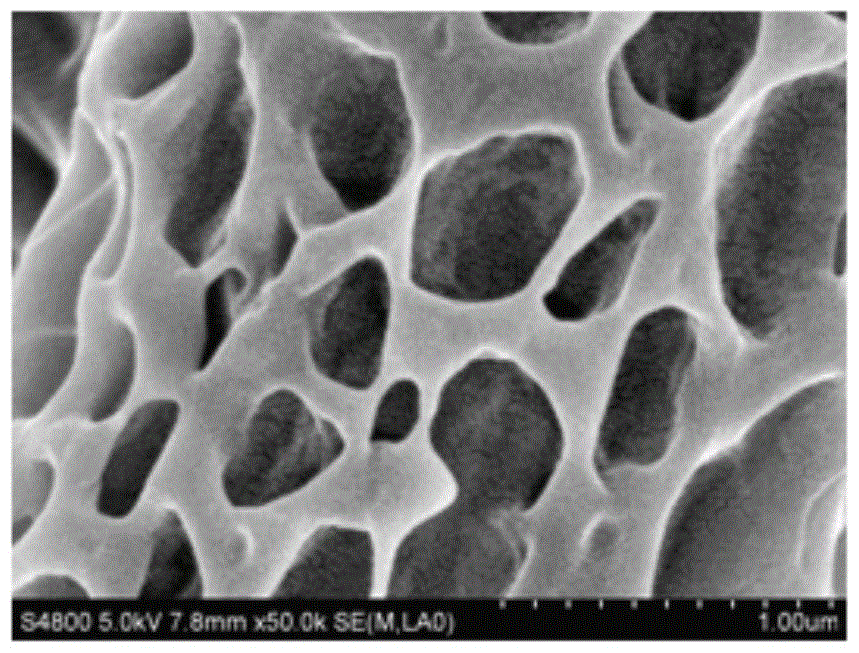

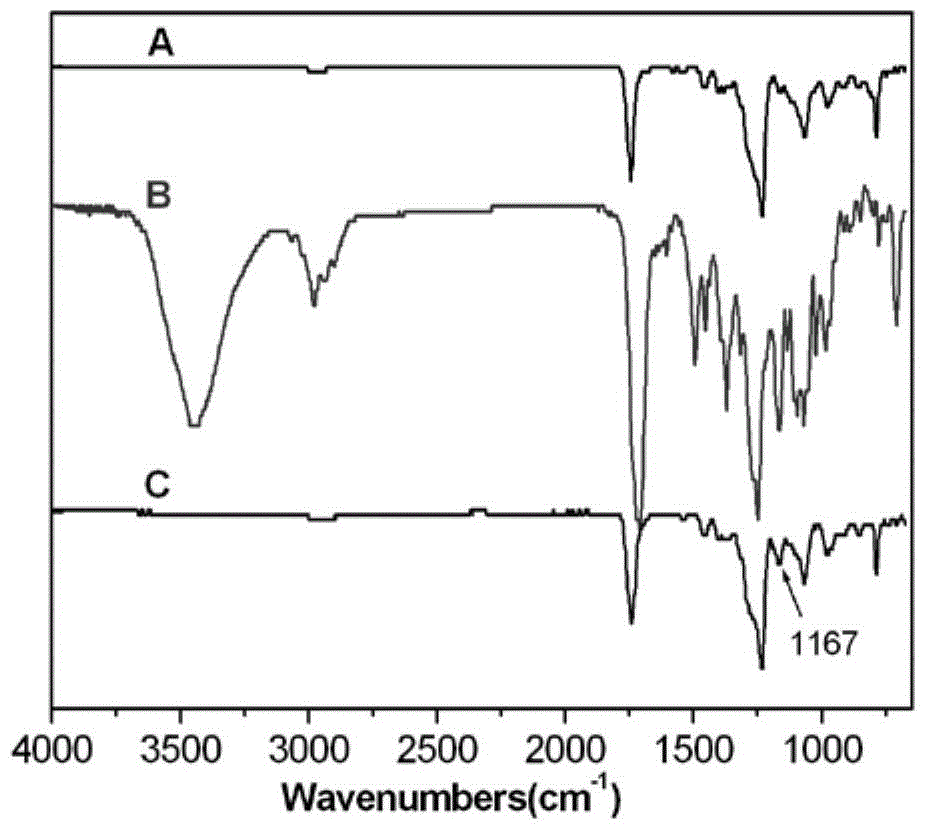

Docetaxel-loaded nanoporous network fibers prepared by high-voltage electrospinning and their applications

A technology of high-voltage electrospinning and docetaxel, which is applied in spinning solution preparation, fiber treatment, filament/thread forming, etc., can solve the problems of inconvenient clinical medication, obvious adverse reactions, and low medication safety, and achieve Good biodegradability, good biocompatibility, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The viscosity-average molecular weight after vacuum drying with a mass ratio of 77:15:8 is 6×10 4 Polypropylene carbonate, viscosity average molecular weight is 6×10 4 The polycaprolactone pellets were mixed with docetaxel, and 0.15% titanium tetrachloride and 0.15% lithium bromide based on the total mass of the previous three materials, and then added chloroform: ethyl acetate: DMSO at a ratio of 80:3:17 A mixed solution with a concentration of 10% is prepared in a mixed solvent; the prepared mixed solution is placed in an electrospinning device connected to a needle with an inner diameter of 0.7mm, and the temperature is 18°C, the humidity is 50%, and the voltage is 17KV. / h injection into fibers, the formed nanofibers are collected by a turntable with a rotating speed of 250 rpm, and the distance between the needle point and the receiving turntable is 18cm; the obtained nanofibers are put into ultrapure water for 30 minutes, repeated 3 times, to fully remove For the...

Embodiment 2

[0035] The viscosity-average molecular weight after vacuum drying in a mass ratio of 85:10:5 is 5×10 4 Polypropylene carbonate with a viscosity average molecular weight of 1.5×10 5 Polycaprolactone pellets are mixed with docetaxel and 0.2% titanium tetrachloride based on the total mass of the previous three materials, and then added to acetone: ethyl acetate: DMF as a mixed solvent of 75:5:20 to prepare A mixed solution with a concentration of 13% was prepared; the prepared mixed solution was placed in an electrospinning device connected to a needle with an inner diameter of 0.8mm, and injected at a flow rate of 7ml / h at a temperature of 20°C, a humidity of 55%, and a voltage of 18KV. The formed nanofibers are collected by a rotating disk with a rotating speed of 300 rpm, and the distance between the needle point and the receiving rotating disk is 20 cm; the resulting nanofibers are put into ultrapure water for ultrasonic treatment for 10 minutes, and repeated 6 times to fully...

Embodiment 3

[0037] The viscosity-average molecular weight after vacuum drying with a mass ratio of 70:20:10 is 8×10 4 Polypropylene carbonate with a viscosity average molecular weight of 1×10 5 The polycaprolactone pellets are mixed with docetaxel and 0.5% lithium bromide based on the total mass of the previous three materials, and then added in chloroform: ethyl acetate: DMF in a mixed solvent of 88:2:10 to prepare a concentration of 7% mixed solution; place the prepared mixed solution in an electrospinning device connected to a needle with an inner diameter of 0.6mm, and inject it into fibers at a flow rate of 4ml / h at a temperature of 18°C, a humidity of 45%, and a voltage of 15KV. The nanofibers are collected by a turntable with a rotating speed of 200 rpm, and the distance between the needle point and the receiving turntable is 18cm; the resulting nanofibers are put into ultrapure water for ultrasonic treatment for 20 minutes, and repeated 4 times to fully remove lithium bromide in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com