Preparation method of SnOx/carbon nano-tube composite material for lithium ion battery

A lithium-ion battery, carbon nanotube technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of capacity decay, large size of tin-based materials, etc., and achieve low cost, controllable material structure, and excellent electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

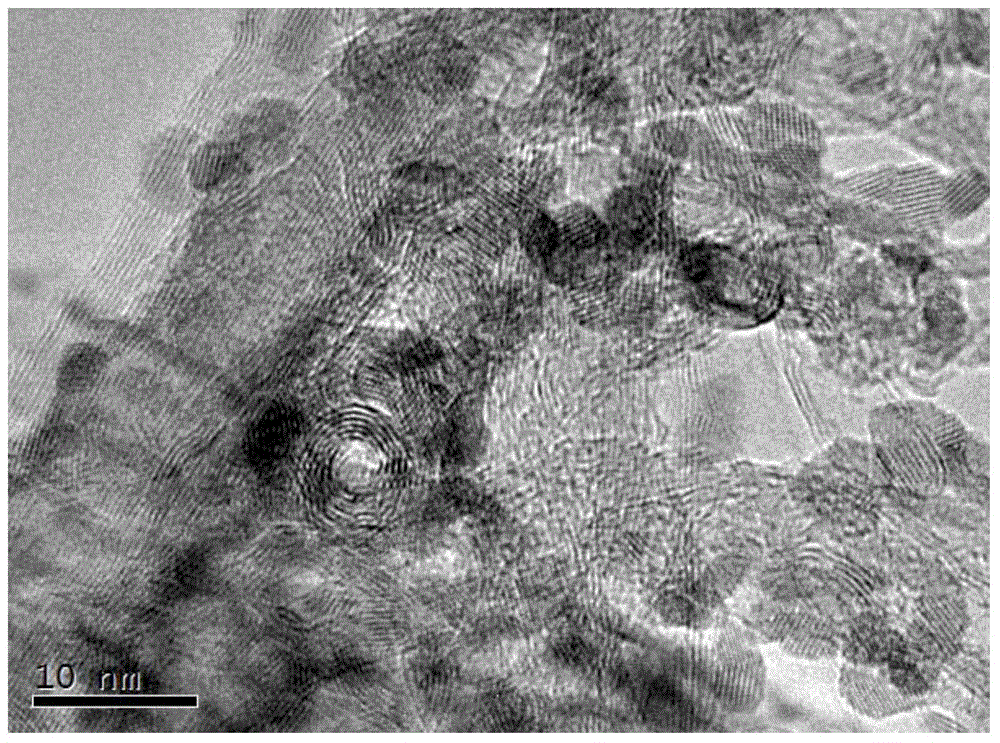

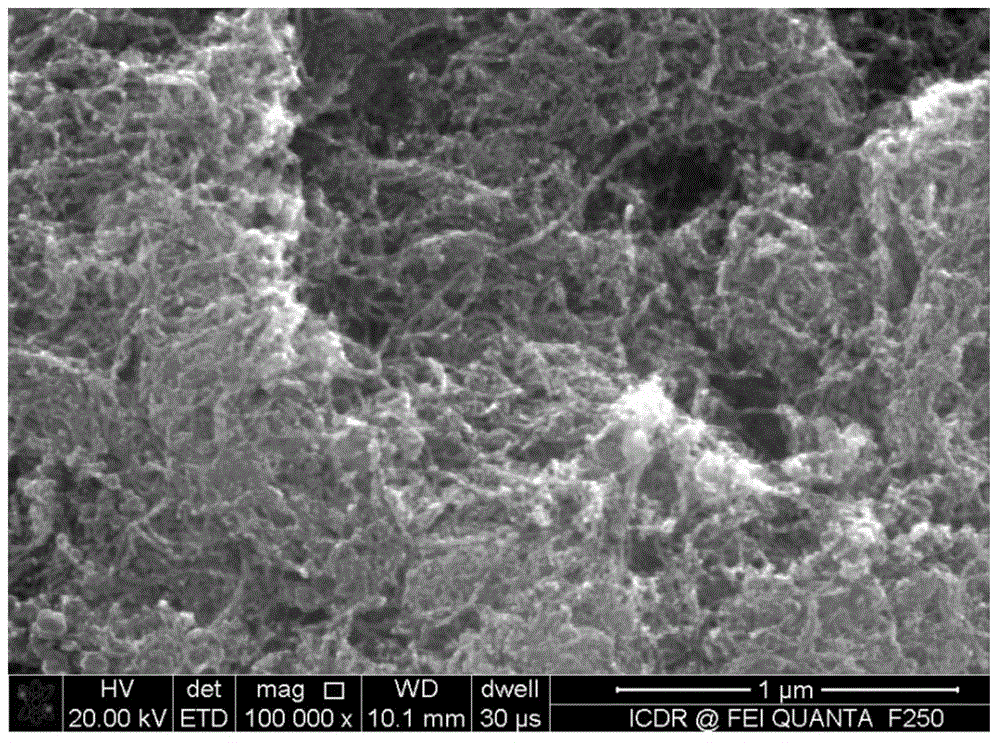

[0022] The invention provides a kind of SnO for lithium ion battery x / The preparation method of carbon nanotube composite material, take tin-based organometallic compound as tin source, mix carbon nanotube and tin source evenly, heat and evaporate until viscous mixture is obtained, the viscous mixture obtained is heat-treated and sintered to obtain SnO x , Carbon nanotube composites.

[0023] The specific technical scheme is as follows:

[0024] 1), first mix the carbon nanotubes and the tin source uniformly to obtain mixture 1; the method for uniformly mixing the carbon nanotubes and the tin source specifically includes: directly mix the tin source and the carbon nanotubes at a mass ratio of 10:1 to 1:1, and Mix evenly by grinding and ball milling.

[0025] 2), heating the mixture 1 in the range of 60-150°C to obtain a viscous product;

[0026] 3) heat-treat the viscous product obtained above at 350-650°C for 1-5h to obtain mixture 2;

[0027] 4), naturally cool the mixt...

Embodiment 1

[0039] Disperse 20mg of multi-walled carbon nanotubes in 5ml of isopropanol, then add 200mg of stannous octoate, stir to mix evenly, and dry at about 100°C, then sinter in a muffle furnace at 350°C for 1 hour in an air atmosphere. Cool naturally to room temperature to get SnO 2 - Multi-walled carbon nanotube composites. with SnO 2 - Carbon nanotube composite material is used as the negative electrode material, mixed with acetylene black and polyacrylic acid (PAA) at a mass ratio of 8:1:1, prepared by adding water to a uniform slurry, coated on copper foil, and dried at 120°C for more than 12 hours , wherein the amount of active material is above 1mg (diameter of the electrode disc is 14mm). The lithium sheet is used as the counter electrode, the American celgard2400 is used as the lithium battery separator, and the electrolyte is 1MLiPF 6 , the solvent is EC+DEC (volume ratio 1:1), assembled into a 2025 button battery. The battery charge and discharge test is carried out o...

Embodiment 2

[0041] Disperse 20mg of multi-walled carbon nanotubes in 5ml of isopropanol, then add 200mg of stannous octoate, stir to make it evenly mixed, and dry it at about 100°C, then transfer it to a tube furnace, and at the same time under the protection of nitrogen at 450 Sintering at ℃ for 1h. Cool naturally to room temperature to get SnO-SnO 2 - Multi-walled carbon nanotube composites. Part of the generated SnO can be removed by dissolving with hydrochloric acid. In the present invention, SnO is not further processed, and the tin oxide-carbon nanotube composite material is directly used as the negative electrode material, mixed with acetylene black and polyacrylic acid (PAA) in a mass ratio of 8:1:1, and water is added to prepare a uniform slurry. Coated on copper foil and dried at 120°C for more than 12 hours, wherein the amount of active material is 0.2-1mg (diameter of electrode disc is 14mm). The lithium sheet is used as the counter electrode, the American celgard2400 is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com