Solvent co-intercalated sodium ion capacitor

A sodium ion and capacitor technology, applied in the field of electrochemical energy storage devices, can solve problems such as unfavorable large-scale application, energy density limitation, and product batch consistency, and achieve favorable rate performance, energy density improvement, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Electrolyte preparation: In an argon-filled glove box, weigh 167.95 grams of sodium hexafluorophosphate (NaPF 6 ), then slowly add sodium hexafluorophosphate into a beaker containing 1 liter of diethylene glycol dimethyl ether (DEGDME) solvent under constant stirring, and form 1mol / L NaPF after completely dissolving 6 / DEGDME Electrolyte.

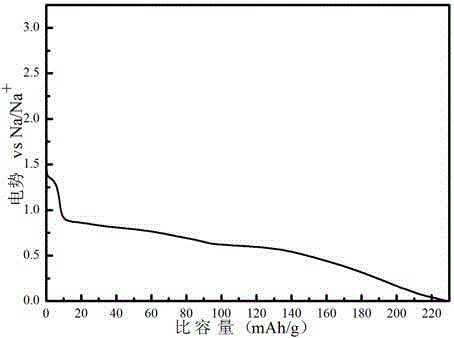

[0044] The production of the negative electrode sheet: the graphitized mesophase carbon microspheres, the conductive agent Super P, and the binder are in a mass ratio of 85:10:5 (the mass ratio of styrene-butadiene rubber emulsion in the binder: sodium carboxymethyl cellulose = 3.5:1.5) mixed and stirred evenly to form a slurry, and the slurry was evenly coated on the copper foil current collector with a porosity of 30% and a thickness of 15 μm. The size of the pole piece was 3cm×5cm, and the nickel strip was welded Ear.

[0045] Production of positive electrode sheet: Mix porous activated carbon, conductive agent Super P, and bin...

Embodiment 2

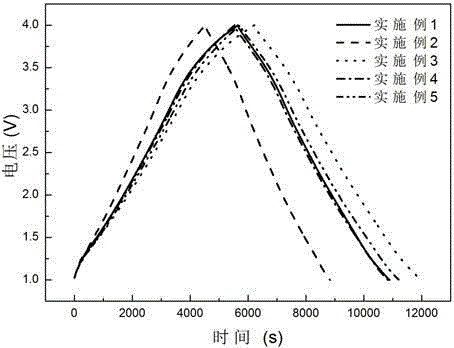

[0052] In Example 1, the solvent in the electrolyte was changed to tetraethylene glycol dimethyl ether, and the rest of the production process was the same as in Example 1.

[0053] Sodium ion capacitor charge and discharge test: After the pre-embedded sodium is completed, the positive electrode and the negative electrode form a loop, and the charge and discharge are carried out with a 1C rate current. The voltage range is 1~4V. The charge and discharge curve is shown in the attached figure 2 , the sodium ion capacitor has an energy density of 91.5Wh / kg based on the sum of the active materials of the two poles at a rate current of 1C; at a rate current of 40C, the energy density is 62.8Wh / kg; after 1000 times of charging and discharging at a rate current of 40C, The capacity retention rate was 96.5%.

Embodiment 3

[0055] In Example 1, the negative electrode material mesophase carbon microspheres were changed to modified natural graphite, and the rest of the manufacturing process was the same as in Example 1.

[0056] Sodium ion capacitor charge and discharge test: After the pre-embedded sodium is completed, the positive electrode and the negative electrode form a loop, and the charge and discharge are carried out with a 1C rate current. The voltage range is 1~4V. The charge and discharge curve is shown in the attached figure 2 , the energy density of the sodium ion capacitor based on the sum of the active materials of the two poles is as high as 113.8 Wh / kg at 1C rate current; at 40C rate current, the energy density is 70.3Wh / kg; after 1000 charge-discharge cycles at 40C rate current, The capacity retention rate was 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com