Graphene quantum dot sensor and its application in detection of trinitrophenol

A technology of graphene quantum dots and trinitrophenol, applied in the field of analytical chemistry, to achieve good photochemical stability, broad application prospects, high selectivity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

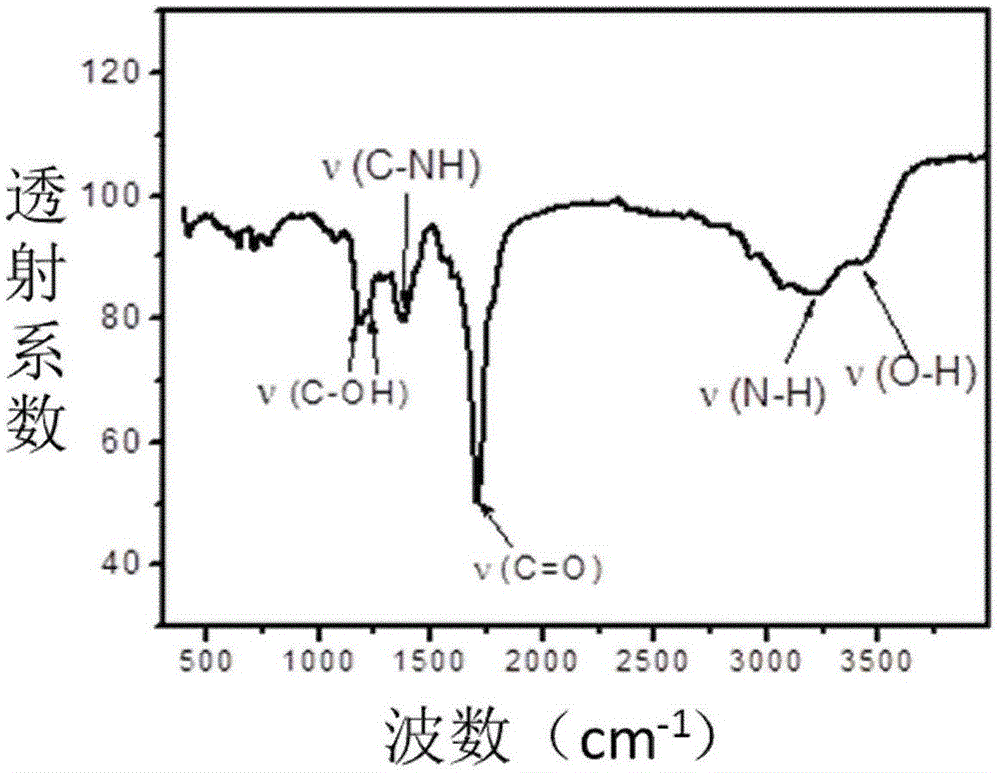

[0023] Mix 2 g of citric acid with 0.5 mL of ammonia water (mass fraction 28%), place in a closed reaction kettle of a microwave heating device, control the temperature at 210° C., and heat for 0.5 hour to obtain nitrogen-doped graphene quantum dots. After the reaction is completed, the fluorescent graphene quantum dots obtained are poured into distilled water, 50 milliliters of distilled water is added for every gram of graphene quantum dots, 5 mL of sodium hydroxide solution is added, the mass fraction of sodium hydroxide solution is 40%, and the pH of the solution is adjusted to 7.0. Transfer the graphene quantum dots to a dialysis bag (35KD), shake and dialyze at room temperature for 24 hours, then wash the product with distilled water and absolute ethanol, and finally dry the purified graphene quantum dots in a vacuum oven at 60°C for 4 hours to obtain the product Graphene quantum dots 1.5g.

Embodiment 2

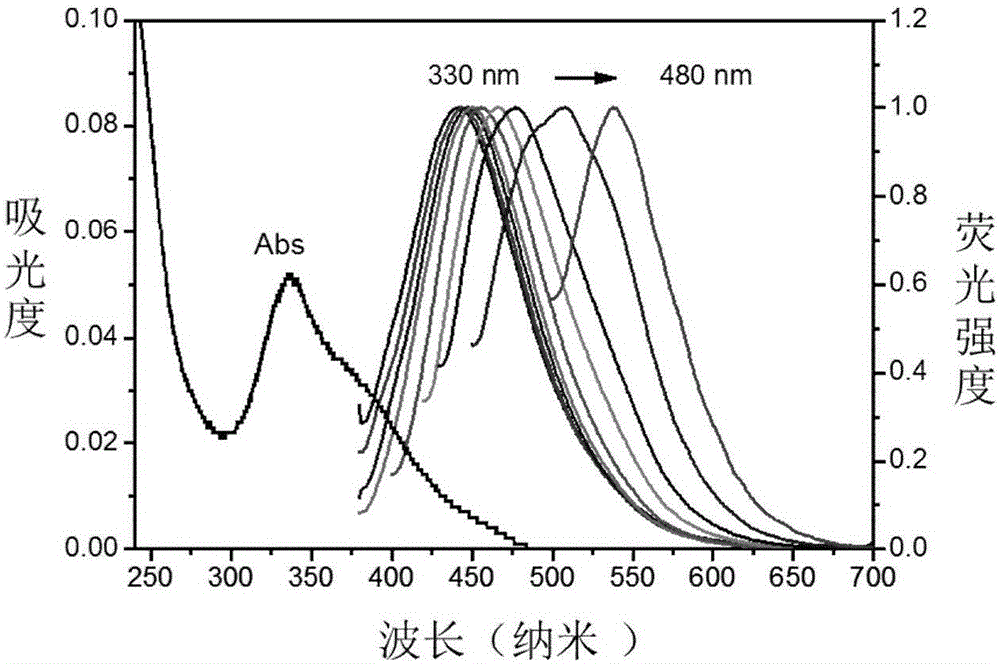

[0025]Mix 10 mg of the purified graphene quantum dots prepared in Example 1 with 10 mL and 20 mg / mL carboxymethyl chitosan solution at 30° C. for 30 min to obtain a uniformly dispersed solution. The quartz thin plate (size 50mm*10mm*5mm) was boiled at 100°C for 30 minutes with a mixture of sulfuric acid with a mass fraction of 98% and hydrogen peroxide with a mass fraction of 30% (mixed volume ratio 0.5:1) to complete silane group activation. After the quartz thin plate was immersed in the mixed solution of graphene quantum dots and carboxymethyl chitosan for 10 minutes, a thin plate with strong fluorescent signal was obtained. Add 10 mL of sodium phosphate buffer solution (24 g of anhydrous sodium dihydrogen phosphate, 6.9 g of sodium hydroxide, and make 1 L with water) to control pH = 8.0, and then immerse the quartz thin plate in 1 mmol / L creatinine solution for 30 min to complete the graphene A layer of functional molecules is formed on the surface of the quantum dot fluor...

Embodiment 3

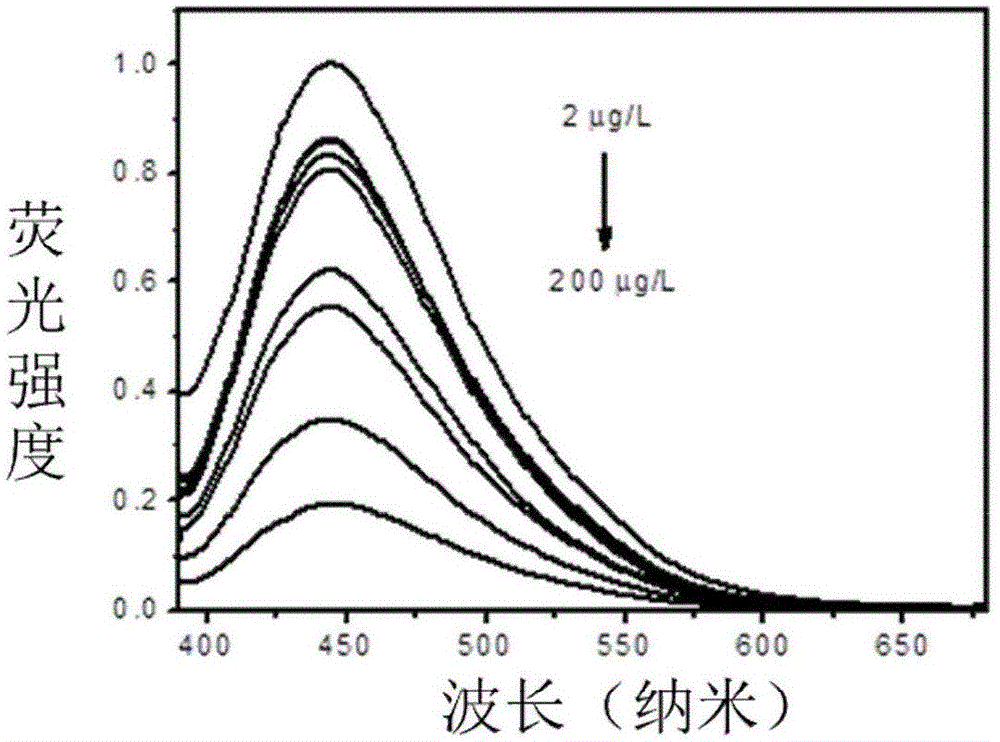

[0027] Add 40% sodium hydroxide solution to adjust the pH of the solution to 11.0, rinse with distilled water and dry with nitrogen. Soak the sensor in a series of known concentrations of trinitrophenol solutions for 5 minutes; then rinse the sensor with distilled water and dry it with nitrogen, place it in a fluorescence photometer, and read the emission wavelength at 443nm under the condition of excitation wavelength 353nm Fluorescence intensity value, with the fluorescence intensity as the ordinate and the concentration of trinitrophenol as the abscissa, draw the analytical work curve; then soak the sensor in the solution sample with an unknown concentration of trinitrophenol, and read at an excitation wavelength of 353nm The fluorescence intensity value at the emission wavelength of 443nm is brought into the analysis working curve, so as to obtain the content of trinitrophenol through calculation.

[0028] Or place the sensor contacting the sample of trinitrophenol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com