Immobilized cationized beta-cyclodextrin chloromethylated polystyrene polymer and method for adsorbing and recovering phenols in industrial wastewater

A technology of chloromethylation and polystyrene, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as troublesome treatment process, inability to recover phenols, inability to recycle, etc., to achieve Low recovery cost, good selective adsorption effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

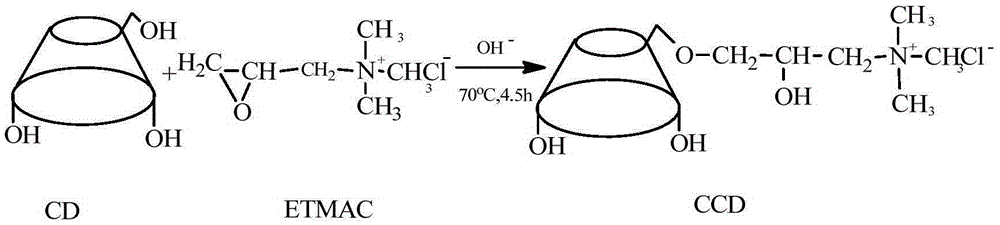

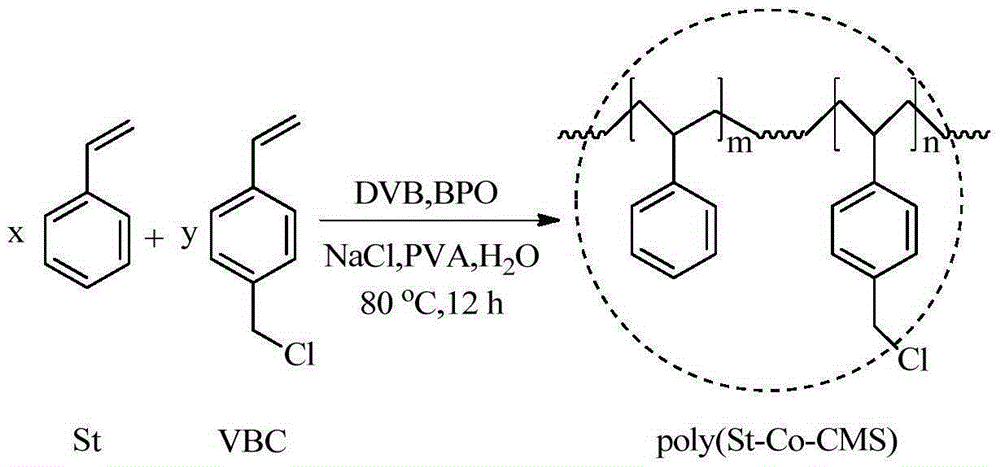

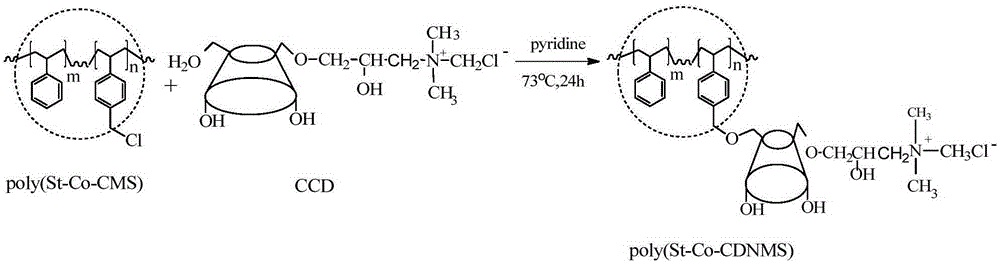

[0033] Preparation of Adsorbent Material (1):

[0034] Dissolve 1g of β-cyclodextrin in 10mL of pure water, stir for 10min to dissolve, add 7g of 2,3-epoxypropyltrimethylammonium chloride (ETMAC), and adjust the pH of the solution to 13 with sodium hydroxide, Stir at 70°C for 4.5h, filter, and evaporate to obtain a brown viscous substance, that is, cationic β-cyclodextrin; dissolve 0.12g of polyvinyl alcohol in 50mL of pure water, add 2.6g of sodium chloride, and add 2.6g of sodium chloride at room temperature to Slowly add a mixed solution of 10g styrene, 1g divinylbenzene, 3.6g p-chloromethylstyrene and 0.16g benzoyl peroxide to the solution, react for 30min, then raise the temperature to 60°C, react for 2h, and continue to raise the temperature To 80°C, react for 10 hours, cool the obtained product, filter, wash with warm water at 60-80°C for several times, and dry in a blast drying oven at 70°C for 6 hours to obtain a light yellow final product, chloromethyl polystyrene; ...

Embodiment 2

[0042] Preparation of Adsorbent Material (2):

[0043] Dissolve 1g of β-cyclodextrin in 10mL of pure water, stir for 10min to dissolve, add 1g of 2,3-epoxypropyltrimethylammonium chloride (ETMAC), and adjust the pH of the solution to 13 with sodium hydroxide, Stir at 70°C for 4.5h, filter, and evaporate to obtain a dark brown viscous substance, that is, cationic β-cyclodextrin; dissolve 0.48g of polyvinyl alcohol in 200mL of pure water, add 6.4g of sodium chloride, and Slowly add a mixed solution of 30g styrene, 4g divinylbenzene, 10g p-chloromethylstyrene and 0.64g benzoyl peroxide to the solution, react for 30min, then raise the temperature to 60°C, react for 2h, continue to raise the temperature to 80°C, react for 10 hours, cool the obtained product, filter, wash with warm water at 60-80°C for several times, and dry in a blast drying oven at 70°C for 6 hours to obtain a yellow final product, chloromethylated polystyrene; Dissolve 1g of cationized β-cyclodextrin in 20mL of ...

Embodiment 3

[0045] Preparation of Adsorbent Material (3):

[0046] Dissolve 1g of β-cyclodextrin in 20mL of pure water, stir for 10min to dissolve, add 10g of 2,3-epoxypropyltrimethylammonium chloride (ETMAC), and adjust the pH of the solution to 13 with sodium hydroxide, Stir at 70°C for 4.5h, filter, and evaporate to obtain a dark brown viscous substance, that is, cationized β-cyclodextrin; dissolve 0.24g of polyvinyl alcohol in 100mL of pure water, add 3.2g of sodium chloride, and Slowly add a mixed solution of 15g styrene, 2g divinylbenzene, 15g p-chloromethylstyrene and 0.32g benzoyl peroxide to the solution, react for 30min, then raise the temperature to 60°C, react for 2h, continue to raise the temperature to 80°C, react for 10 hours, cool the obtained product, filter, wash with warm water at 60-80°C for several times, and dry in a blast drying oven at 70°C for 6 hours to obtain a yellow final product, chloromethyl polystyrene; Dissolve 1g of cationized β-cyclodextrin in 10mL of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com