Epoxysuccinic acid-itaconic acid copolymerized green scale and corrosion inhibitor and preparation method therefor

A technology of epoxy succinic acid and scale and corrosion inhibitors, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds. Scale dispersion performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

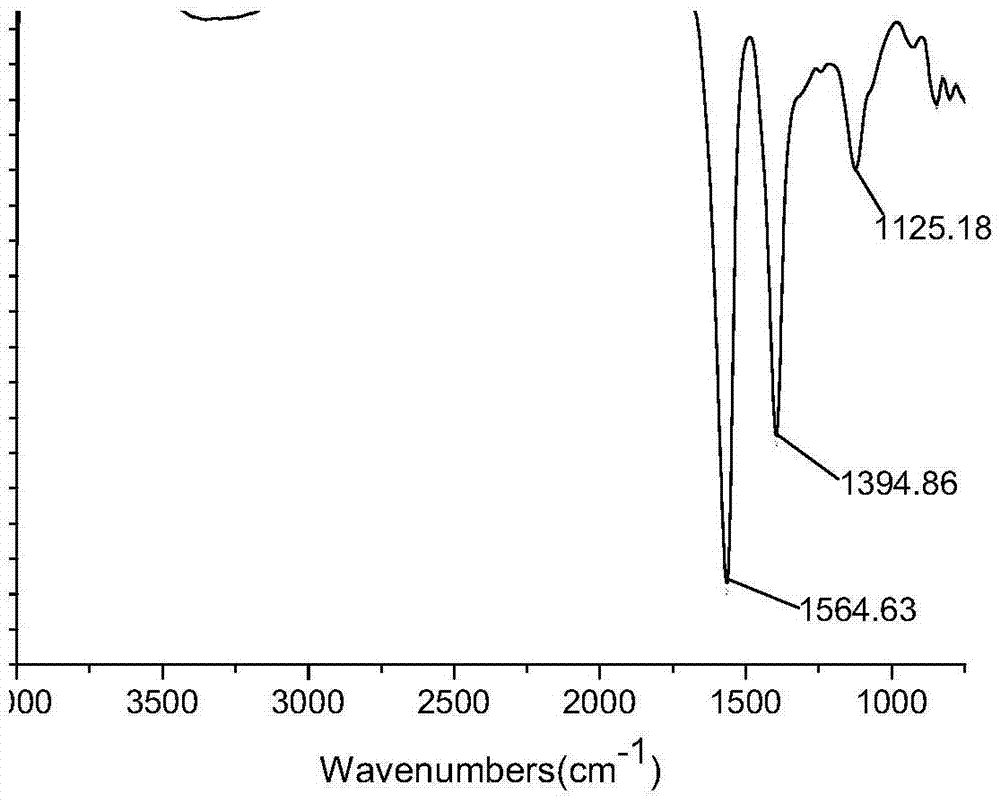

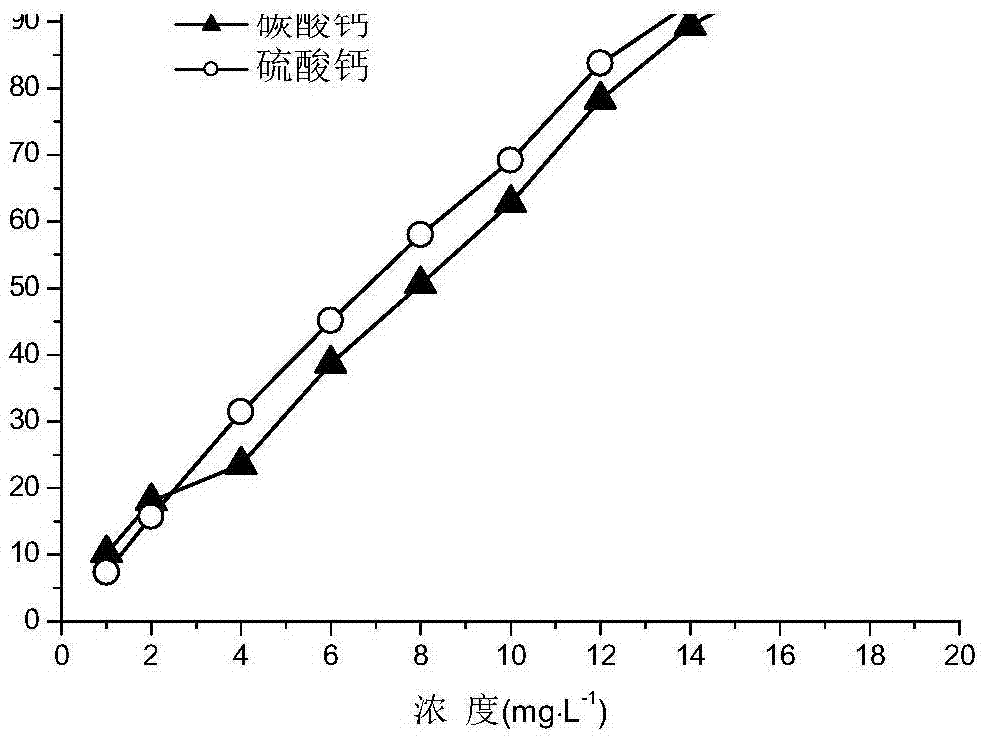

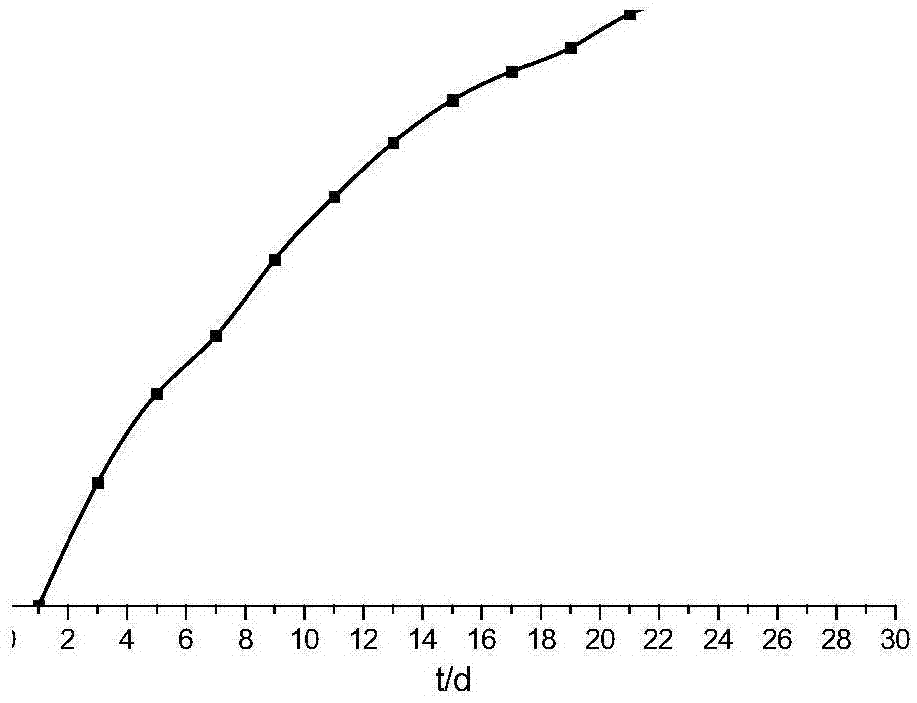

[0030] Synthesize epoxy succinic acid-itaconic acid copolymer according to the following steps, add maleic anhydride and deionized water in the four-necked flask equipped with reflux condenser, constant pressure dropping funnel, thermometer and stirrer, after stirring and dissolving, Slowly add 50% (mass fraction) of sodium hydroxide solution dropwise to hydrolyze maleic anhydride into maleic acid, heat it in a water bath to a certain temperature, add a quantitative amount of catalyst sodium tungstate, add the oxidant hydrogen peroxide dropwise into the constant pressure dropping funnel and use it at the same time NaOH solution adjusts the pH value and reacts to generate epoxysuccinic acid. According to the ratio of the amount of itaconic acid and epoxy succinic acid to 3:1 or 4:1 or 5:1, add itaconic acid to the flask, and put the flask into a place that has been adjusted to 75°C or 85°C or Heat in a constant temperature water bath at 95°C, stir to dissolve the itaconic acid,...

Embodiment 2

[0034] Embodiment 2 adds itaconic acid in the four-necked flask that has generated epoxysuccinic acid, adjusts itaconic acid addition, reacts by the ratio of the amount of substance of itaconic acid listed in table 2 and epoxysuccinic acid, Stir to dissolve the itaconic acid, control the reaction temperature to 85° C., and neutralize with 50% (mass fraction) sodium hydroxide solution until the pH is 9-10. Use a constant pressure dropping funnel to add the initiator ammonium persulfate at a constant speed. The mass of ammonium persulfate is 11% of the total mass of the monomer. Under nitrogen protection, heat to reflux and stir mechanically. The dropping time is 0.5h. After the dropping is completed, continue Insulation reaction 4h. Cool and stop stirring to obtain the product epoxysuccinic acid-itaconic acid copolymer solution of the present invention. The results of the research on the scale inhibition performance of the copolymerized products on calcium carbonate are listed...

Embodiment 3

[0038] Add 4.91g (0.05mol) of maleic anhydride and 8mL of deionized water into a four-neck flask, stir to dissolve, slowly add 8g of 50% (mass fraction) sodium hydroxide solution dropwise, heat to 70°C in a water bath, and add 0.08g of catalyst Sodium tungstate, the oxidant hydrogen peroxide was added dropwise to the constant pressure dropping funnel, and the dropping time was 20 minutes. At the same time, 50% (mass fraction) sodium hydroxide solution was used to adjust the pH value to 7~8, and the reaction was continued for 2 hours, and the reaction produced 6.49g (0.0492mol) epoxysuccinic acid, the yield of epoxysuccinic acid was 98.3%. According to the material ratio of itaconic acid and epoxy succinic acid is 4:1, add 25.56g (0.197mol) itaconic acid to the flask, and heat it in a water bath to 70°C or 75°C or 80°C or 85°C or 90°C ℃, stirring to dissolve the itaconic acid, and continue to use 50% (mass fraction) sodium hydroxide solution to adjust the pH value to about 8-9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com