A kind of negative lead paste of lead-carbon battery

A negative electrode paste and lead-carbon battery technology, which is applied in the construction of battery electrodes, lead-acid batteries, lead-acid batteries, etc., can solve the problems of hydrogen suppression effect decline, uneven size, poor consistency, etc., and achieve the increase of hydrogen evolution impedance, increase Utilization rate, the effect of reducing hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

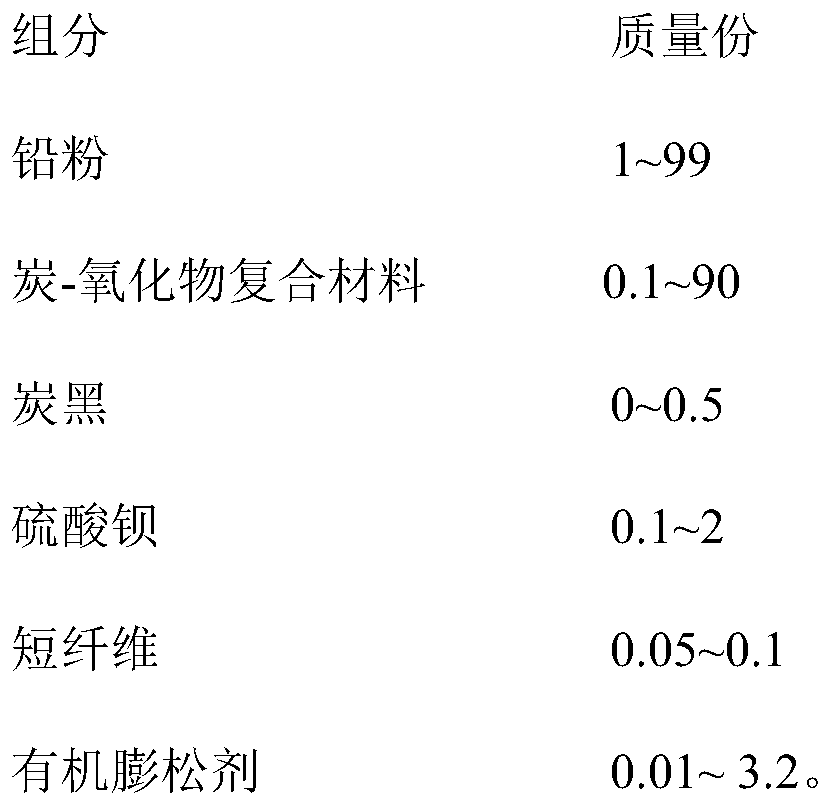

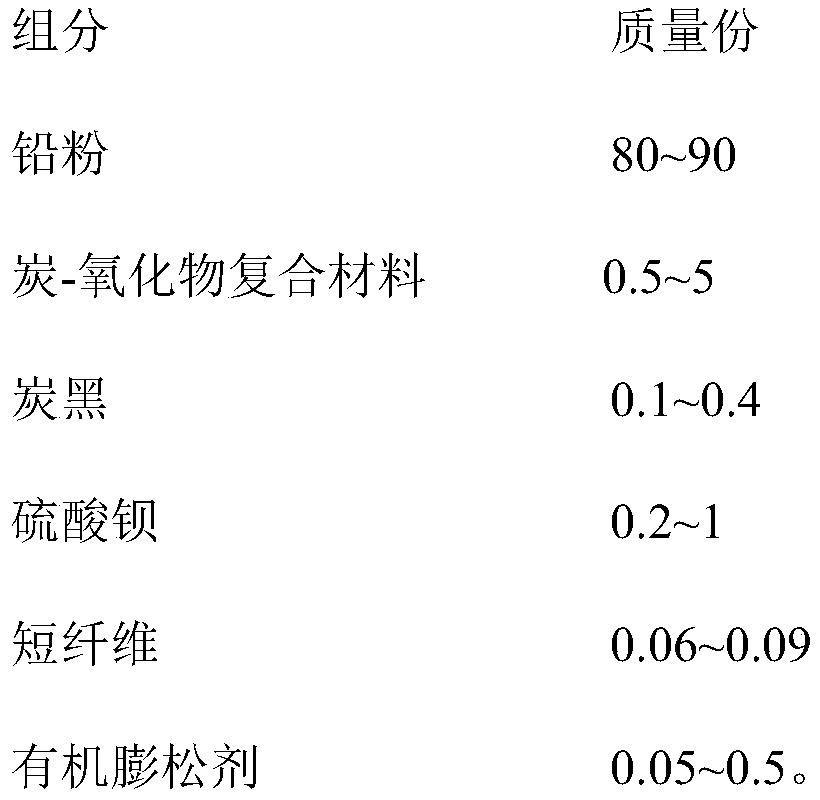

Method used

Image

Examples

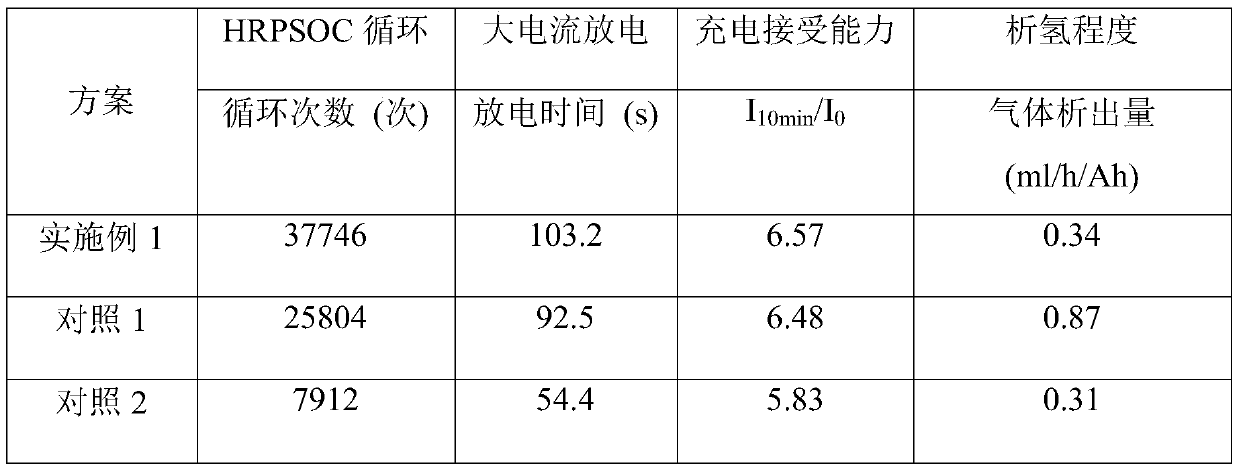

Embodiment 1

[0057] Preparation of activated carbon-gallium oxide-indium oxide composite material: use physical vapor deposition to deposit gallium oxide and indium oxide on the surface and pores of activated carbon, and the specific surface area of activated carbon is 1800-2000m 2 / g, the particle size D50 is 10-20m, and the weight ratio of activated carbon: gallium oxide: indium oxide is 24:1:1.

[0058] Preparation of lead carbon negative lead paste: the solid raw materials of the lead paste include 97 parts of lead powder, 2 parts of activated carbon-gallium oxide-indium oxide composite material, 0.2 part of carbon black, 0.5 part of barium sulfate, and 0.1 part of lignin sulfonate Sodium acid, 0.1 part of humic acid and 0.1 part of short fiber, the apparent density of the lead paste is 4.0-4.4g / cm 3 .

[0059] Two sets of reference negative electrode pastes were prepared.

[0060] The solid raw materials of the first group of negative electrode pastes include 97 parts of lead powd...

Embodiment 2

[0072] Preparation of graphene-zinc oxide composite material: use hydrothermal method to deposit zinc oxide on the surface of graphene, wherein the number of carbon atomic layers of graphene is within 10 layers, and the specific surface area is 300-400m 2 / g, the weight ratio of graphene: zinc oxide is 23:2.

[0073] Preparation of lead carbon negative electrode paste: the solid raw materials of the paste include 99 parts of lead powder, 0.5 parts of graphene-zinc oxide composite material, 0.25 parts of carbon black, 1 part of barium sulfate, and 0.01 part of sodium lignosulfonate , 0.2 parts of humic acid and 0.06 parts of short fibers, the apparent density of the lead paste is 4.0-4.4g / cm 3 .

[0074] Apply the above two kinds of lead pastes on the grid to make the negative plate, and the positive plate is assembled, filled with acid and activated according to the normal production process to produce 2V15Ah valve-regulated sealed lead-acid battery.

[0075] Two sets of ref...

Embodiment 3

[0088] Preparation of carbon black-graphite-bismuth oxide composite material: use a chemical water bath method to coat a thin layer of bismuth oxide on the surface of carbon black and graphite, and the specific surface area of carbon black is 1000-1200m 2 / g, particle size D 50 5~10m, the specific surface area of graphite is 8~10m 2 / g, particle size D 50 The thickness of bismuth oxide thin layer is about 100nm. The mass ratio of carbon black, graphite and bismuth oxide in the composite material is 10:9:1.

[0089] Preparation of lead carbon negative lead paste: the solid raw materials of the lead paste include 98 parts of lead powder, 5 parts of carbon black-graphite-bismuth oxide composite material, 0.2 part of barium sulfate, 0.05 part of sodium lignosulfonate, 0.05 part of Humic acid and 0.09 parts of short fibers, the apparent density of the lead paste is 4.0-4.4g / cm 3 .

[0090] Apply the above two kinds of lead pastes on the grid to make the negative plate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com