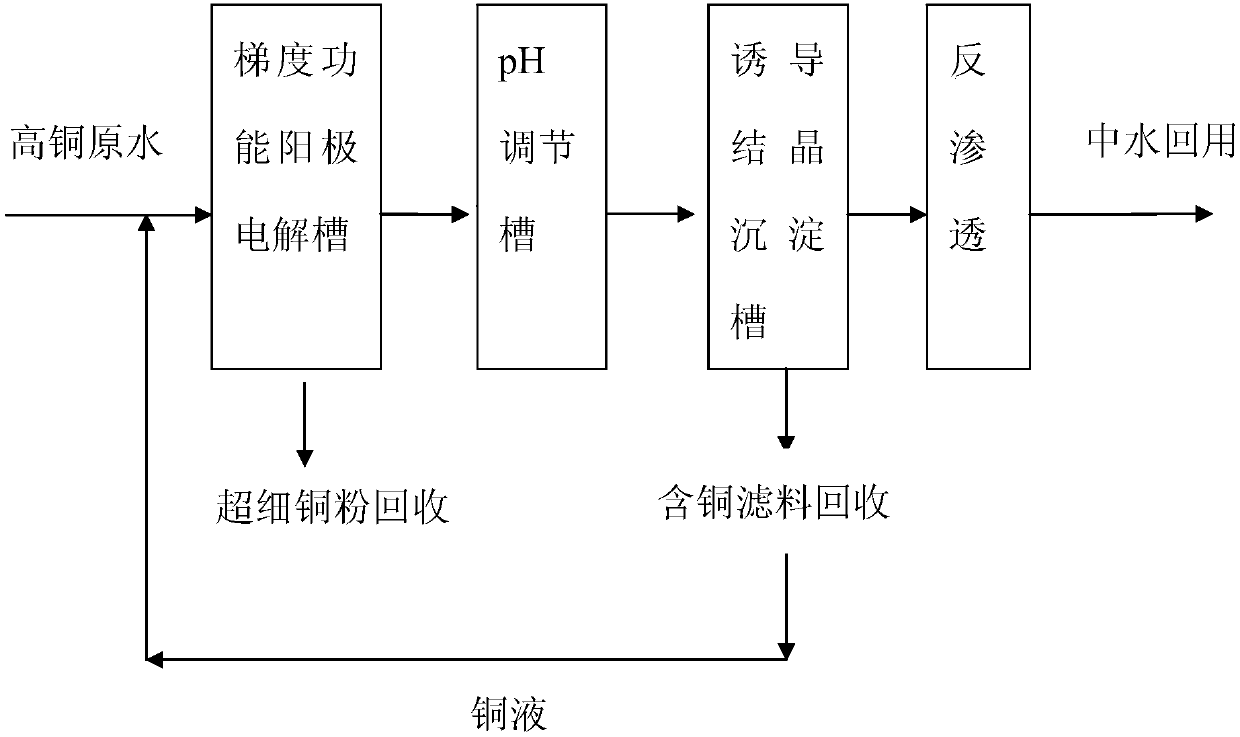

Treatment method of high-copper circuit board wastewater based on gradient functional anode electrolysis

A gradient function, anode electrolysis technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficulty in obtaining reclaimed water that meets the reuse standard, poor water treatment; patent literature , large consumption of pharmaceutical agents, etc., to achieve the effect of meeting the requirements of reuse, simple equipment and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Ti / Sn-Sb-Ce gradient functional anode:

[0034] (1) Coarsening of the titanium plate: the Ti substrate is immersed in an oxalic acid solution with a mass percentage of 10%, boiled for 1 hour, and rinsed with deionized water. At this time, the surface of the Ti substrate becomes a rough pitted surface;

[0035] (2) Coating solution configuration: first, three different molar ratios (100:10:1, 60:10:1, 40:10:1) of SnCl 4 , SbCl 3 and CeCl 3 Dissolve in 6M hydrochloric acid to obtain a 2g / L solution, then add 2 times the volume of absolute ethanol to obtain a coating solution;

[0036] (3) Electrode preparation: the three kinds of coating liquids are painted on the surface of the titanium substrate in the order of brushing and drying, and the drying temperature after brushing is 120°C for 30 minutes; The Ti / Sn-Sb-Ce gradient functional anode was prepared by firing in a muffle furnace for 2 hours at a time.

[0037] Take the treatment of high copper-conta...

Embodiment 2

[0047] Take the treatment of high copper-containing wastewater from a circuit board factory in Wuxi as an example. The parameters of each unit are as follows:

[0048] (1) Gradient function anode electrolysis process: anode current density 150mA / cm 2 , Ti / Sn-Sb-Ce gradient functional anode was prepared as in Example 1. The cathode is a copper plate, and the electrolytic residence time is 2h;

[0049] (2) Induced crystallization sedimentation tank: the influent pH is 9, the precipitating agent is sodium sulfide, the concentration of sodium sulfide is 20%, and the molar ratio of dosing is 2:1; the filter material is activated carbon, the particle size is 0.25mm, and the hydraulic retention time is 2h.

[0050] (3) The reverse osmosis membrane model is PROC10 of Hyde Energy Company, and the nominal water production capacity is 1.65m 3 / h.

[0051] Raw water concentration: copper ion 18g / L, COD 3000mg / L, pH 3;

[0052] After gradient function anode electrolysis: copper ion 1...

Embodiment 3

[0057] Take the treatment of high copper-containing wastewater from a circuit board factory in Wuxi as an example. The parameters of each unit are as follows:

[0058] (1) Gradient function anode electrolysis process: anode current density 150mA / cm 2 , Ti / Sn-Sb-Ce gradient functional anode was prepared as in Example 1. The cathode is a titanium plate, and the electrolytic residence time is 1.5h;

[0059] (2) Induced crystallization sedimentation tank: the influent pH is 9, the precipitating agent is sodium sulfide solution, the mass concentration of sodium sulfide is 20%, the molar ratio of dosing is 2:1; the filter material is volcanic rock, the particle size is 0.25mm, and the hydraulic retention The time is 1.5h.

[0060] (3) The reverse osmosis membrane model is PROC10 of Hyde Energy Company, and the nominal water production capacity is 1.65m 3 / h.

[0061] Raw water concentration: copper ion 20g / L, COD 4000mg / L, pH 3;

[0062] After gradient function anode electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com