Sugarless gum with high collagen peptide content and preparation method thereof

A technology of collagen peptide and high collagen, which is applied in the field of sugar-free chewing gum with high collagen peptide content and its preparation, can solve the problem of low active peptide addition, high active peptide addition, and the inability to guarantee the daily intake of consumers and other issues to achieve the effect of flavor coordination and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Components of sugar-free chewing gum: gum base 20%, sugar alcohol 60% (wherein xylitol 30%, sorbitol 15%, maltitol 10%, erythritol 5%), collagen peptide (tilapia Collagen peptide derived from skin, on a dry basis, protein content ≥ 90%, peptide content ≥ 85%, the proportion of protein hydrolyzate with a relative molecular mass less than 1000Da ≥ 80%, the following examples are the same) 10%, chitosan oligosaccharide ( Oligomeric glucosamine with 2-10 degrees of polymerization, the content is 90.8%, the following examples are the same) 5%, citric acid 1.0%, vitamin C 1.0%, aspartame 1.0%, lecithin 1.0%, flavor and fragrance 1.0% %.

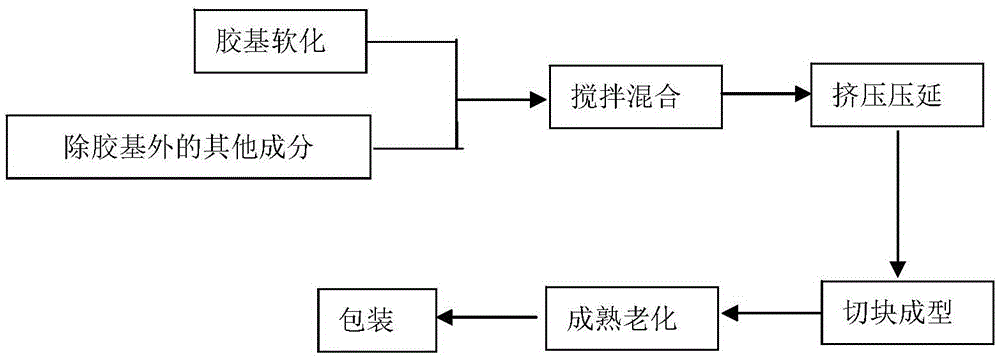

[0037] In this embodiment, through the following processes (such as figure 1 shown) to prepare sugar-free chewing gum:

[0038] (1) Gum base softening: soften the gum base at 50°C for 4 hours in a drying room or an electric heating oven;

[0039] (2) Mixing and stirring: Add the softened gum base and other ingredients into the mixer, and ...

Embodiment 2

[0043] Components of sugar-free chewing gum: gum base 30%, sugar alcohol 42.75% (xylitol 25%, sorbitol 8%, erythritol 5%, D-mannitol 4.75%), collagen peptide 15%, Chitooligosaccharide 7.5%, citric acid 2.0%, vitamin C 0.5%, sucralose 0.5%, lecithin 1.0%, flavor and fragrance 0.75%.

[0044] In the present embodiment, prepare sugar-free chewing gum by following process:

[0045] (1) Gum base softening: Soften the gum base at 60°C for 3 hours in a drying room or an electric heating oven;

[0046] (2) Mixing and stirring: Add the softened gum base and other ingredients into the mixer, and stir for 15 minutes at a stirring temperature of 60°C;

[0047] (3) Cooling, extrusion and calendering: the stirred sugar billet is stored and cooled until the temperature of the material is lower than 40°C, and then put into the extruder. Note that the extruder should be preheated about 30 minutes in advance during extrusion and calendering. About 32°C, the temperature of the extrusion head o...

Embodiment 3

[0050] Components of sugar-free chewing gum: gum base 25%, sugar alcohol 49% (including xylitol 24%, sorbitol 15%, maltitol 10%), collagen peptide 12%, chitosan oligosaccharide 8%, sour agent 2.5% (citric acid 1.0%, malic acid 1.5%), vitamin C 1.2%, sweetener 0.8% (sucralose 0.3%, aspartame 0.5%), lecithin 0.5%, flavor and fragrance 1.0% .

[0051] In the present embodiment, prepare sugar-free chewing gum by following process:

[0052] (1) Gum base softening: soften the gum base at 55°C for 3.5 hours in a drying room or an electric heating oven;

[0053] (2) Mixing and stirring: Add the softened gum base and other ingredients into the mixer, and stir for 15 minutes at a stirring temperature of 55°C;

[0054] (3) Cooling, extrusion and calendering: the stirred sugar billet is stored and cooled until the temperature of the material is lower than 40°C, and then put into the extruder. Note that the extruder should be preheated about 30 minutes in advance during extrusion and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com