Oral EPA(Eicoeapentaenoic acid) O/W type nanoemulsion and preparation method thereof

A nano-emulsion and nano-emulsion technology, applied in dairy products, applications, milk preparations, etc., can solve the problems of loss of the inner wall of blood vessels, use of many auxiliary materials, hardening, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

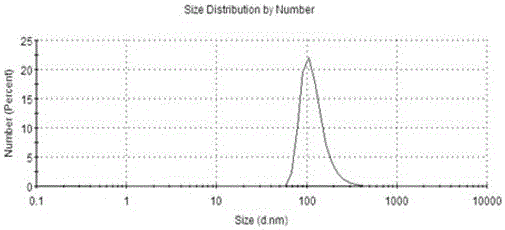

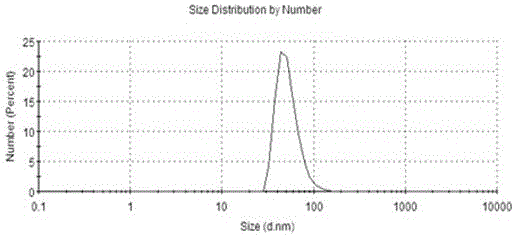

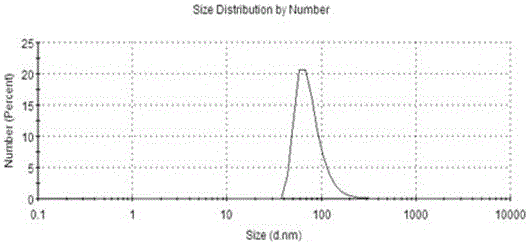

Image

Examples

Embodiment 1

[0043] (1) Accurately weigh 30g of EPA glyceride with a purity of 92%, control the temperature of the heating medium at 25°C, and mix with 4.1g ethyl linolenate, 0.2g ethyl oleate, 0.150g polyoxyethylene 40 under the conditions of inert gas and 200rpm rotation speed Stir hydrogenated castor oil (RH-40), 100g Tween-80, 70g polyethylene glycol 400, and 0.2g ascorbic acid for 20 minutes to make it fully mixed, then slowly raise the temperature to 55°C to obtain a uniformly dispersed oil phase component, and set aside ;

[0044] (2) Accurately weigh 30g of polyethylene glycol and 1.5g of sodium sulfate into 618g of water, and control the temperature of the heating medium at 50°C. At this time, the stirring speed should be controlled at 300rpm, and the mixing time should be 10 minutes. After mixing evenly, heat up to the pasteurization temperature for pasteurization, and cool down to 40°C to obtain uniformly dispersed water phase components;

[0045] (3) Under an inert gas environ...

Embodiment 2

[0047] (1) Accurately weigh 15g of EPA ethyl ester with a purity of 92%, control the temperature of the heating medium at 25°C, and mix with 3.1g of ethyl linolenate, 0.4g of ethyl palmitoleate, 150g of polyoxyethylene 40 under the conditions of inert gas and 250rpm Stir hydrogenated castor oil (RH-40), 50g Tween-80, 70g ethylene glycol, 30g 1,2-propanediol, 0.25g natural vitamin E, 0.25g tert-butyl hydroquinone for 10 minutes to fully mix Slowly heat up to 55°C to obtain evenly dispersed oil phase components, set aside;

[0048] (2) Accurately weigh 35g of ethylene glycol, 15g of 1,2-propanediol, 1.5g of sodium sulfate, and 1.5g of potassium chloride into 667g of water, and control the temperature of the heating medium at 58°C. At this time, the stirring speed should be controlled at 450rpm. for 8 minutes. After mixing evenly, heat up to the pasteurization temperature for pasteurization, and cool down to 45°C to obtain uniformly dispersed water phase components;

[0049] (3...

Embodiment 3

[0051] (1) Accurately weigh 67g of EPA glyceride with a purity of 96%, control the temperature of the heating medium at 35°C, and mix with 0.32g ethyl palmitoleate, 4.6g ethyl linoleate, 170g lecithin, 110g Tween-20, 107g ethylene glycol, 85g glycerin and 0.78g dibutyl hydroxytoluene were stirred for 25 minutes to make them fully mixed, then slowly heated to 55°C to obtain uniformly dispersed oil phase components, which were set aside;

[0052] (2) Accurately weigh 11g of ethylene glycol, 25g of glycerol, and 9.3g of sodium citrate into 468.2g of water, and control the temperature of the heating medium at 60°C. At this time, the stirring speed should be controlled at 200rpm, and the mixing time should be 15 minutes . After mixing evenly, heat up to the pasteurization temperature for pasteurization, and cool down to 50°C to obtain uniformly dispersed water phase components;

[0053] (3) Under an inert gas environment, stir the oil phase components obtained in step (1) at a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com